Welding material for quickly welding and repairing defects of HT300 grey iron castings and repair method

A welding material and rapid welding technology, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of gray iron casting defects that are difficult to deal with, achieve the enhancement of weld crack resistance, reduce white spots and Crack tendency, effect of rapid welding repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

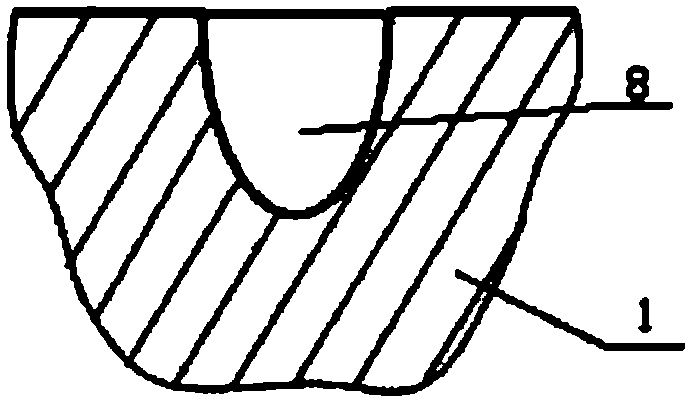

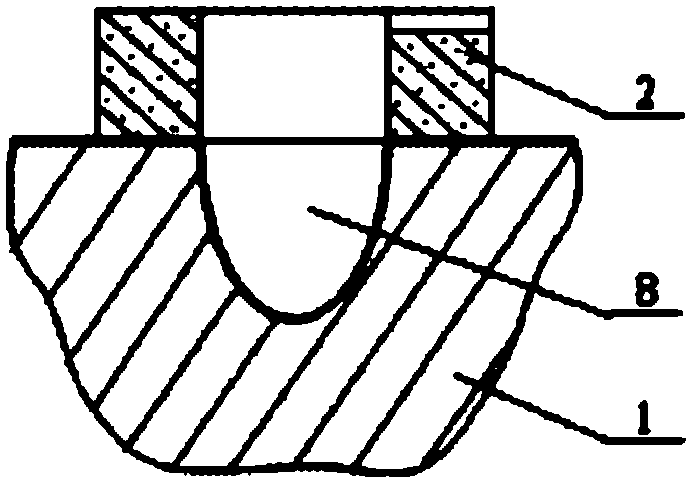

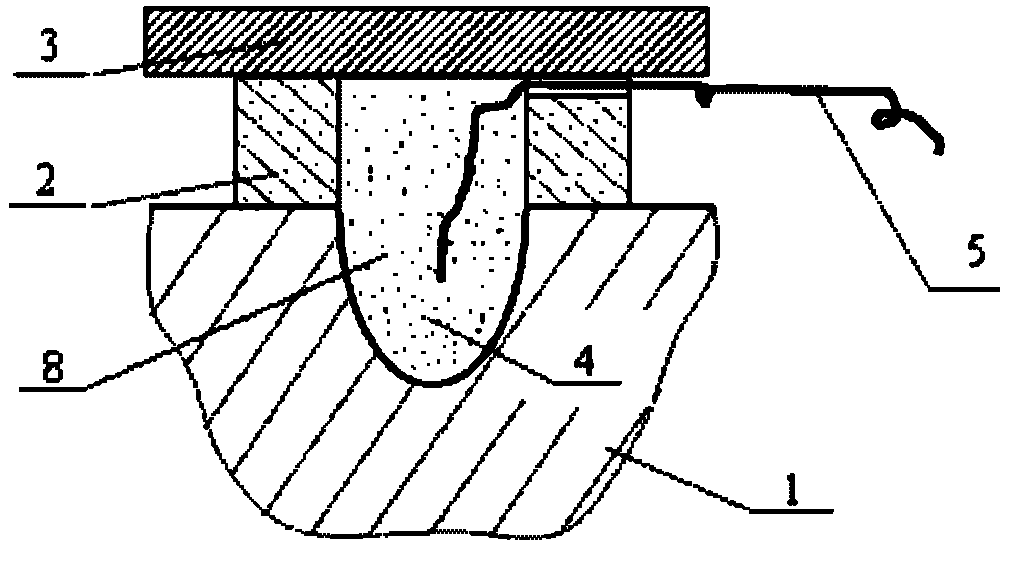

Method used

Image

Examples

Embodiment 1

[0048] First, the welding consumables for the welding of large HT300 gray iron castings are prepared, which are composed of powders of the following components mixed uniformly by weight percentage:

[0049] Fe 2 o 3 34%, Al 27%; Na 2 CO 3 1.0%, Na 2 B 4 o 7 4.0%, CaF 2 4.0%, CaO 8.0%, SiO 2 1.5%; graphite 3.0%, pig iron 7.0%, 75 ferrosilicon 4.0%, nickel 0.5%, bismuth 0.2%, 60 silicon calcium 1.0%, 30 ferrotitanium 1.0%, 75 ferromanganese 1.4%, 50 ferrochrome 1.0%, 50 0.5% ferromolybdenum, 0.5% tin bronze, 0.2% ferro-18 boron, 0.2% ferro-60 vanadium, the total weight is 100%.

[0050] Carry out welding according to aforementioned repairing method again, in the above-mentioned embodiment, the chemical composition (Wt%) of the welding powder deposited metal after repairing is respectively:

[0051] C is 2.70, Si is 1.70, Mn is 0.96, Mo is 0.03, Cr is 0.05, Cu is 0.06, Ti is 0.02, V is 0.01, S is 0.08, and P is 0.15.

[0052] The mechanical properties of the weld m...

Embodiment 2

[0054] First, the welding consumables for the welding of large HT300 gray iron castings are prepared, which are composed of powders of the following components mixed uniformly by weight percentage:

[0055] Fe 2 o 3 32%, Al 28%; Na 2 CO 3 1.5%, Na 2 B 4 o 7 5.0%, CaF 2 6.0%, CaO7.0%%, SiO 2 1.0%; graphite 3.5%, pig iron 6.0%, 75 ferrosilicon 3.5%, nickel 0.6%, bismuth 0.1%, 60 silicon calcium 1.5%, 30 ferrotitanium 0.5%, 75 ferromanganese 1.3%, 50 ferrochrome 1.2%, 50 0.6% ferromolybdenum, 0.5% tin bronze, 0.1% ferro-18 boron, 0.1% ferro-60 vanadium, the total weight is 100%.

[0056] Carry out welding according to aforementioned repairing method again, in the above-mentioned embodiment, the chemical composition (Wt%) of the welding powder deposited metal after repairing is respectively:

[0057] C is 2.63, Si is 1.66, Mn is 0.91, Mo is 0.03, Cr is 0.06, Cu is 0.05, Ti is 0.01, V is 0.01, S is 0.07, and P is 0.17.

[0058] The mechanical properties of the weld m...

Embodiment 3

[0060] First, the welding consumables for the welding of large HT300 gray iron castings are prepared, which are composed of powders of the following components mixed uniformly by weight percentage:

[0061] Fe 2 o 3 35%, Al 26%; Na 2 CO 3 1.0%, Na 2 B 4 o 7 4.0%, CaF 2 4.0%, CaO 8.0%, SiO 2 0.5%; graphite 3.5%, pig iron 8.0%, 75 ferrosilicon 3.5%, nickel 0.5%, bismuth 0.2%, 60 silicon calcium 1.0%, 30 ferrotitanium 1.0%, 75 ferromanganese 1.4%, 50 ferrochrome 1.0%, 50 0.5% ferromolybdenum, 0.5% tin bronze, 0.2% ferro-18 boron, 0.2% ferro-60 vanadium, the total weight is 100%.

[0062] Carry out welding according to aforementioned repairing method again, in the above-mentioned embodiment, the chemical composition (Wt%) of the welding powder deposited metal after repairing is respectively:

[0063] C is 2.89, Si is 1.84, Mn is 0.90, Mo is 0.03, Cr is 0.03, Cu is 0.05, Ti is 0.01, V is 0.01, S is 0.07, and P is 0.16.

[0064] The mechanical properties of the weld m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com