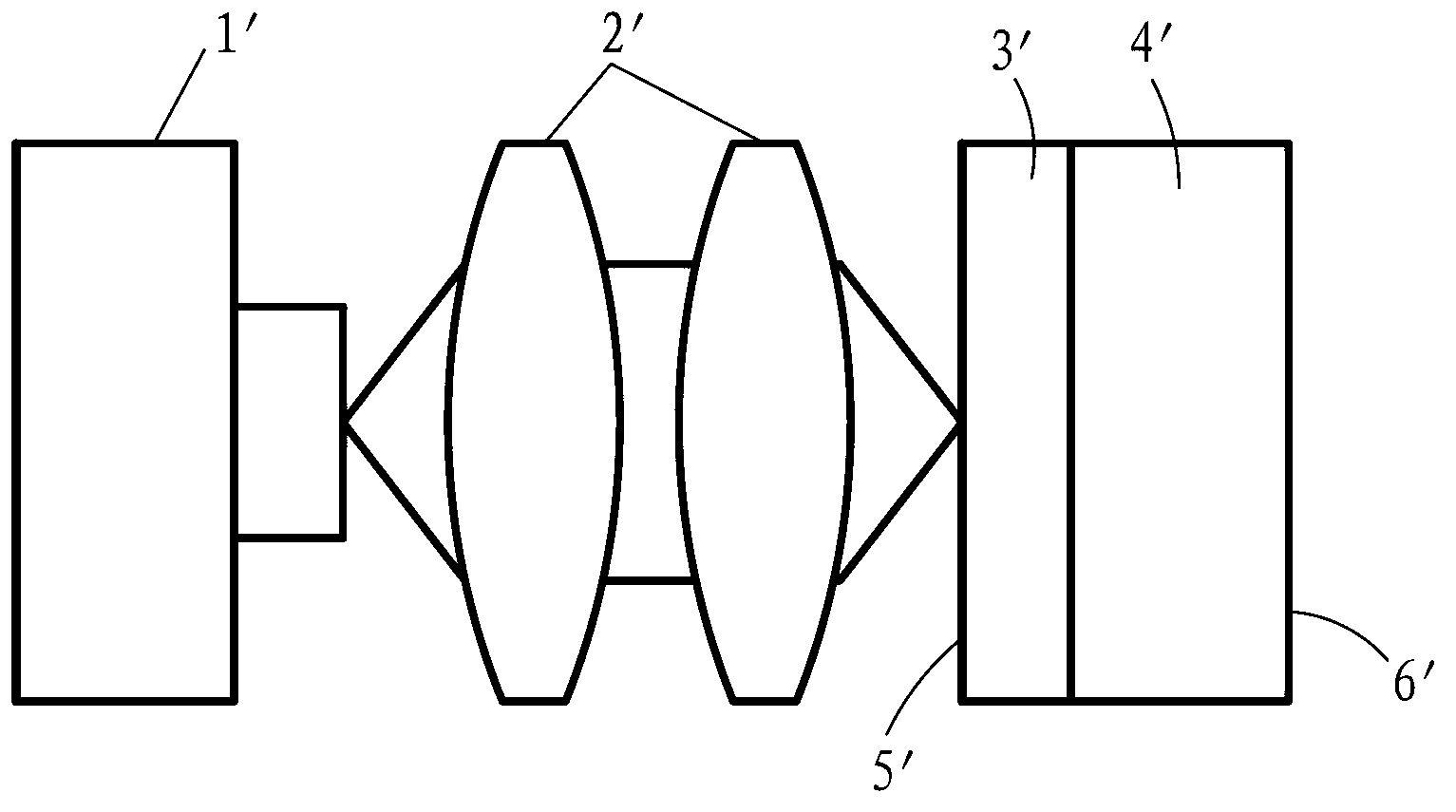

Intracavity frequency doubling microchip laser and preparation method thereof

A microchip laser and intracavity frequency doubling technology, which is applied to the structure/shape of laser parts and optical resonators, can solve the problems of increasing cost and increasing volume, and achieve cost saving, reducing adjustment man-hours, The effect of saving crystal material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

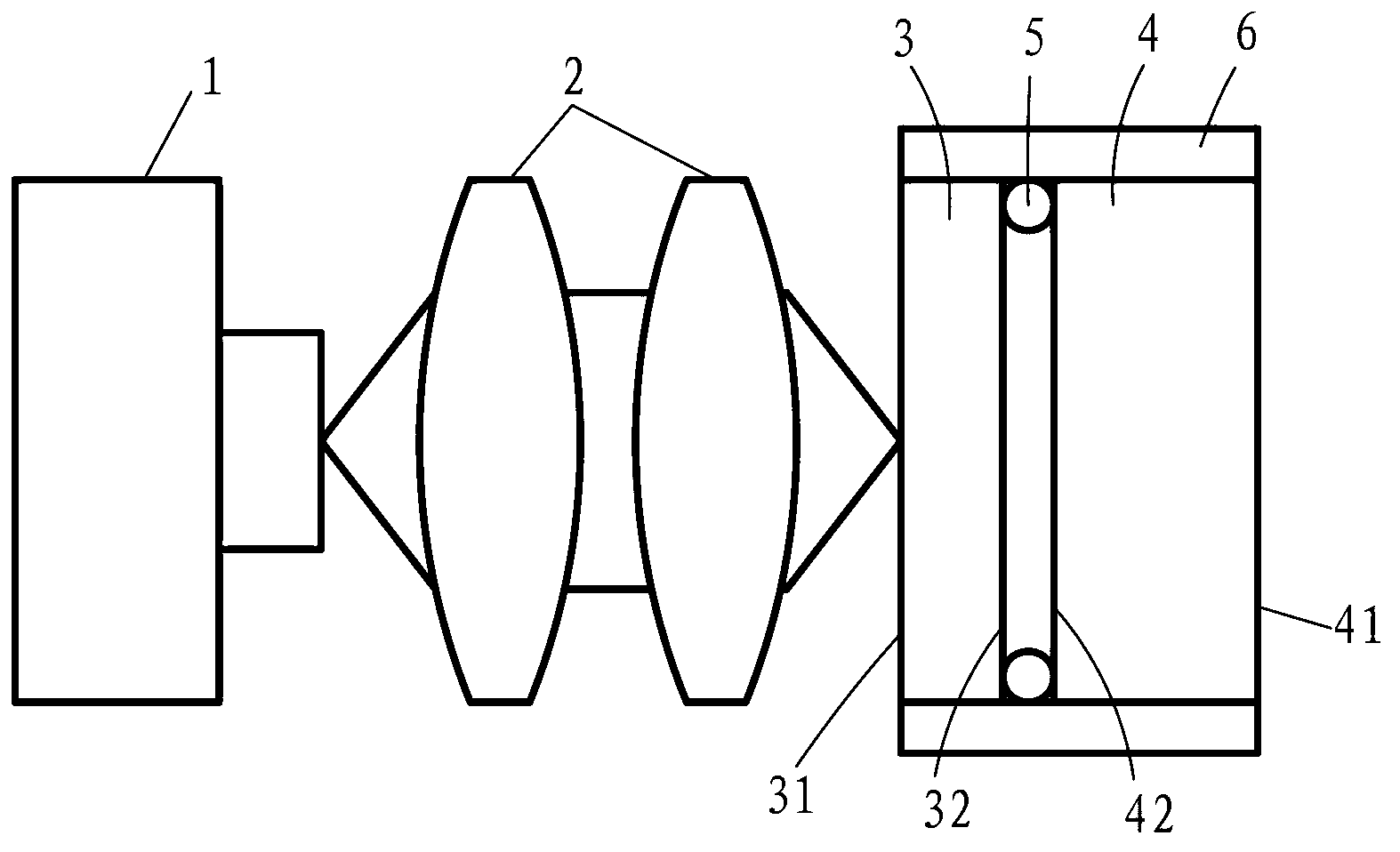

[0024] The preparation method of intracavity frequency doubling microchip laser of the present invention comprises

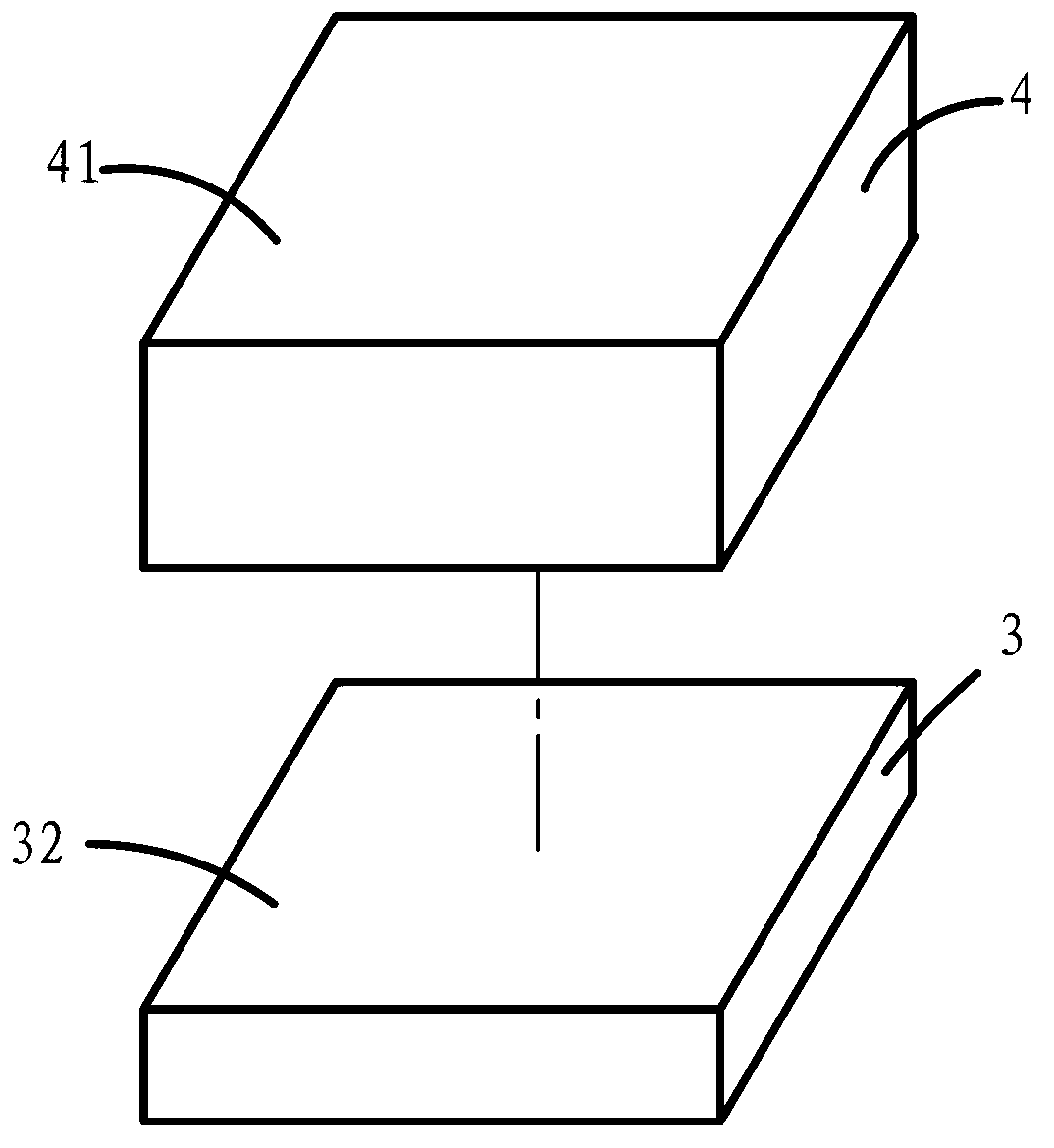

[0025] Step 10, processing the laser crystal 3 and the frequency doubling crystal 4 into high-precision parallel flat plates;

[0026] Step 20, plate a film with high reflectivity of the fundamental frequency light and frequency doubled light on the front face of the laser crystal 3, as the cavity mirror 31 in front of the laser cavity, plate the high reflectivity of the fundamental frequency light on the rear end face of the frequency double crystal 4, A thin film with high transmittance for frequency doubled light is used as the rear cavity mirror 41 of the laser cavity;

[0027] Step 30, coating the rear end face of the laser crystal and the front face of the frequency doubling crystal with anti-reflection coatings 32 and 42 for fundamental frequency light;

[0028] Step 40. Place the laser crystal and the frequency doubling crystal on one side of the anti-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com