Optical fiber current sensing system

A technology of optical fiber current sensing and current, applied in voltage/current isolation, measuring current/voltage, measuring electrical variables, etc., can solve problems such as application limitations, achieve simple and convenient installation process, improve polarization performance, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Throughout the drawings, the same reference numerals denote the same elements.

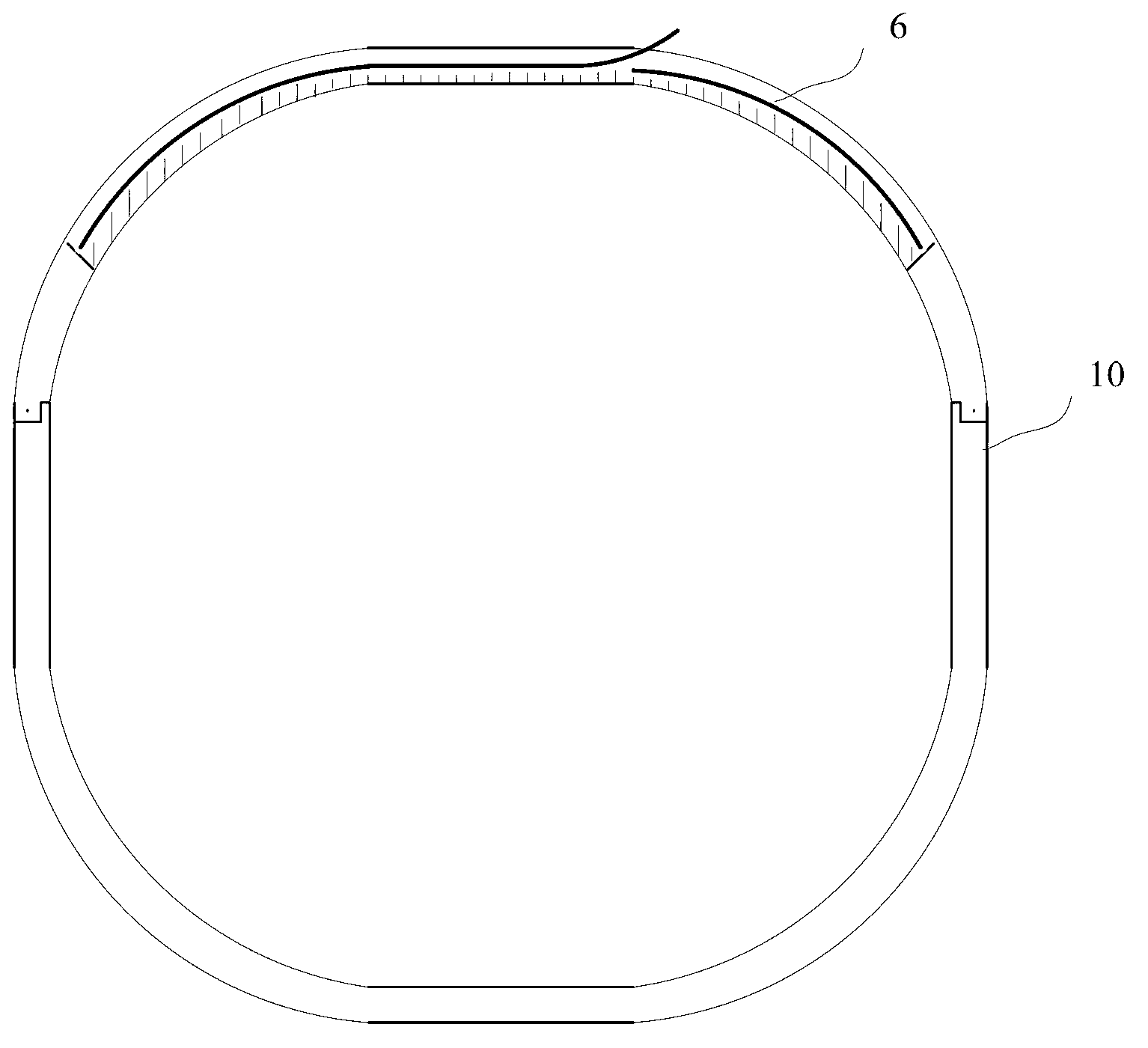

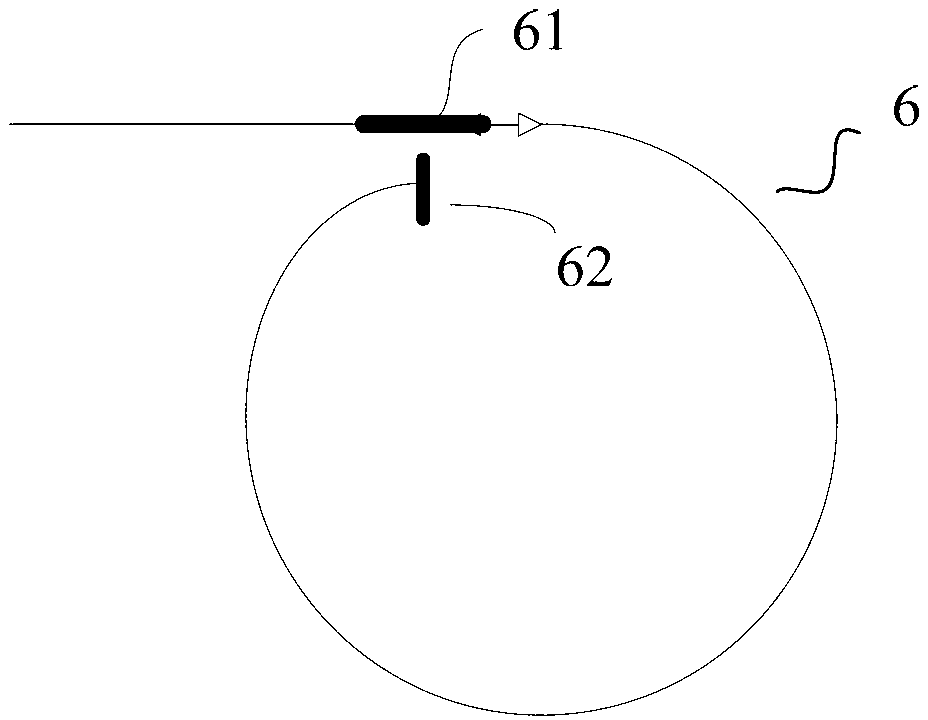

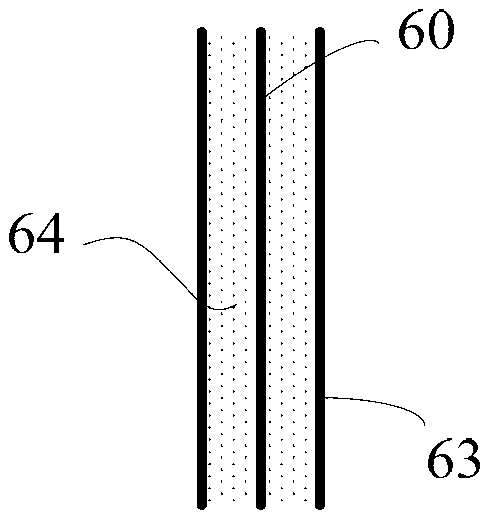

[0038] In order to enable the sensing optical fiber to be installed with openings on site, an embodiment of the present invention provides an optical fiber current sensing device for measuring current passing through a conductor. Such as figure 1 As shown, the fiber optic current sensing device includes a sensing fiber 6 and a bracket 10 for installing the sensing fiber. The sensing fiber 6 includes an optical fiber and a flexible protective sheath covering the optical fiber. The bracket 10 includes a first portion and a second portion each having a fiber optic groove. The first part and the second part are detachably connected to form a closed ring structure surrounding the conductor under test, and the fiber groove of the first part and the fiber groove of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com