Stage lamp thermal system

A technology for stage lamps and hot zones, which is applied to lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as burnout and fan failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

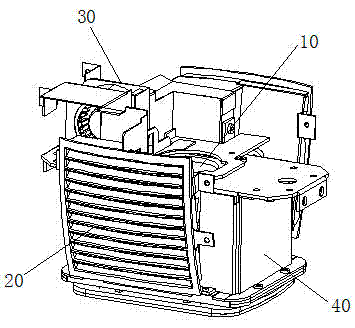

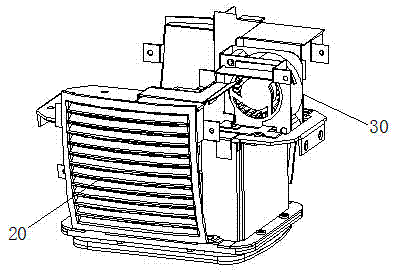

[0036] Such as Figure 1 to Figure 8 Shown is the first embodiment of the stage light thermal system of the present invention, as figure 1 , figure 2 As shown, it includes a light emitting unit 10, an air inlet chamber 20, an air blast chamber 30 and an air outlet chamber 40, as image 3 , Figure 4 As shown, the air inlet cavity 20 is provided with a system air inlet 21, a fan 22 and a flow distribution mechanism 23, as Figure 6 As shown, the air distribution mechanism 23 divides the air inlet cavity 20 into a cold area L and a hot area R, wherein the system air inlet 21 is located in the cold area L, a part of the fan 22 is located in the cold area L, and the other part is located in the hot area R, and the cold area L is connected to the air blowing chamber 30 and the air outlet chamber 40 , the hot zone R is connected to the air outlet chamber 40 , the air blast chamber 30 is connected to the air outlet chamber 40 , and the light emitting unit 10 is installed in the a...

Embodiment 2

[0042] Such as Figure 9 Shown is the second embodiment of the stage light thermal system of the present invention. As an improvement to Embodiment 1, the stage light thermal system of this embodiment further includes a heat insulating element 50 arranged outside the light emitting unit 10, and the heat insulating element 50 separates the light Functional components within the lamp cavity of the unit and thermal system. Among them, the functional components include color chip disk, pattern disk, CMY color mixing system, etc.

[0043] Further, the heat insulation element 50 is 8-15 mm away from the light-emitting unit 10 and covers the top of the light-emitting unit at an angle of 5-30° with respect to the installation plane of the light-emitting unit 10 .

[0044] The thermal system of the stage light in the embodiment of the present invention is arranged around the light-emitting unit to form an air inlet chamber, an air blast chamber, and an air outlet chamber. In the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com