Radiator for LED lamp

A technology of LED lamps and radiators, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of unfavorable LED lamp structure design and increased costs, and achieve compact structure design Thermal resistance, preventing local effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

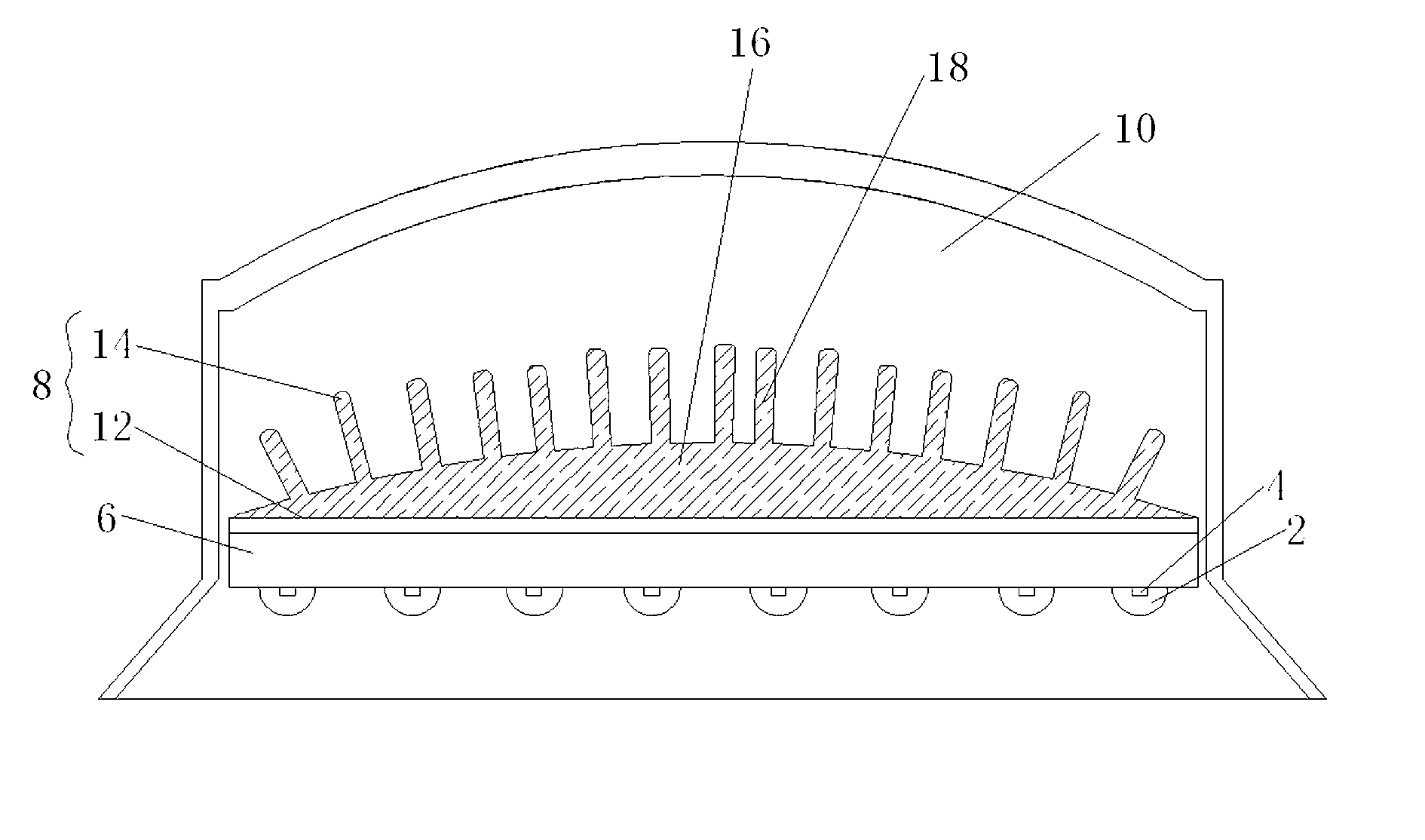

[0017] Such as figure 1 As shown, a heat sink suitable for LED lamps is shown. The LED lamp includes LED lamp beads 2, chips 4, circuit boards 6, heat sinks 8, and a housing 10 that seals and accommodates the above components. The chip 4 is packaged in the LED lamp bead 2, and the LED lamp bead 2 is welded on the circuit board 6, and the LED lamp bead 2 is powered by an external power supply device, wherein, the radiator 8 is arranged on the back of the circuit board 6 (non-main component welding surface), the two can be bonded together by heat-conducting insulating glue, and can also be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com