Automobile water pump water seal cooling mechanism

A cooling mechanism and water pump technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of poor cooling effect, high production cost, complex mechanism, etc., to avoid falling off and sealing problems, simple processing, easy to install and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

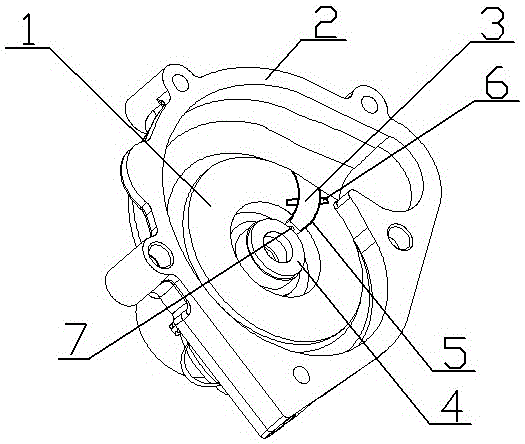

[0015] Such as figure 1 As shown, the present invention discloses an automobile water pump water seal cooling mechanism, comprising a water pump housing 2 and a water seal 4, an annular boss 1 is arranged inside the water pump housing 2, and a groove 5 is arranged on the boss 1, and the A blocking slug 3 is arranged in the groove 5 , and a flow guide tube 7 is arranged in the slugging block 3 .

[0016] Further, the groove 5, the plug block 3 and the guide tube 7 are all arc-shaped structures.

[0017] The blocking block 3 is provided with a positioning pin 6 .

[0018] Both the plugging block 3 and the positioning pin 6 are injection molded parts.

[0019] The guide tube 7 is pre-embedded connected with the plug block 3 .

[0020] The water inlet of the guide pipe 7 is arranged at the water outlet of the water pump housing 2 .

[0021] The diameter of the water inlet of the guide pipe 7 is larger than the diameter of the water outlet.

[0022] The inner hole of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com