Variable crucible ratio monocrystal silicon growth method

A growth method, single crystal silicon technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems affecting device alignment and consistency, secondary defects, and insignificant gettering effect, etc., to achieve Strong compatibility, good axial uniformity, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

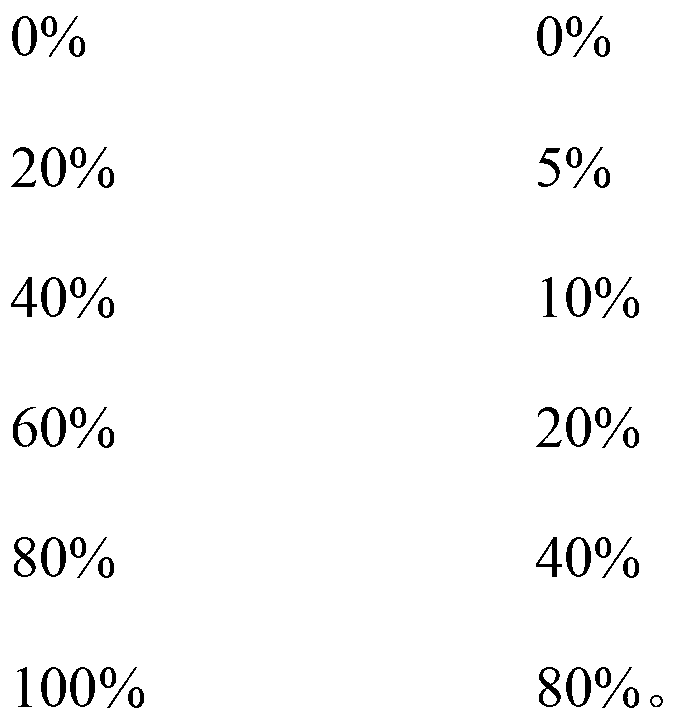

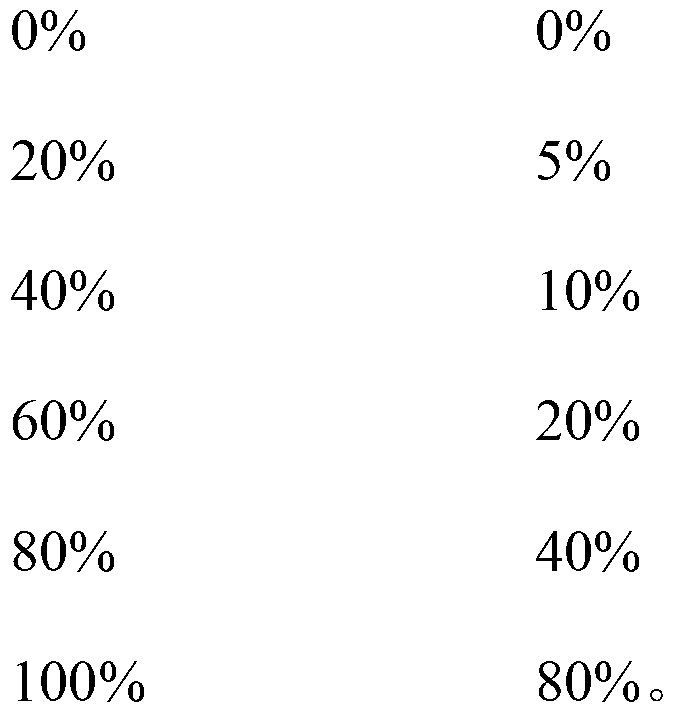

Image

Examples

Embodiment 1

[0020] CG6000 single crystal furnace is adopted, with 16-inch thermal field, 25kg polycrystalline material, the target resistivity of the drawn monocrystalline silicon head is 35 ohm cm, the type of monocrystalline silicon is N type, and the size of monocrystalline silicon is 4 inches. A constant pressure of 40 torr, an argon gas flow rate of 40 slpm, a crucible rotation speed of 5 rpm, and a crystal rotation speed of 12 rpm were adopted.

[0021] Specific steps are as follows:

[0022] (1) Clean the thermal field, single crystal furnace, and quartz crucible;

[0023] (2) Carefully put the polycrystal and dopant into the quartz crucible;

[0024] (3) Close the single crystal furnace, flush the single crystal furnace with argon several times and evacuate it, and check the vacuum leak rate;

[0025] (4) Turn on the argon gas flow, turn on the heater to heat up, and melt the polysilicon;

[0026] (5) After the polycrystal is completely melted, reduce the power of the heater an...

Embodiment 2

[0033] CG6000 single crystal furnace is adopted, with 16-inch thermal field, 30kg polycrystalline material, the target resistivity of the drawn monocrystalline silicon head is 50 ohm cm, the type of monocrystalline silicon is N type, and the size of monocrystalline silicon is 5 inches. A constant pressure of 35 torr, an argon gas flow rate of 50 slpm, a crucible rotation speed of 6 rpm, and a crystal rotation speed of 14 rpm were adopted.

[0034] Specific steps are as follows:

[0035] (1) Clean the thermal field, single crystal furnace, and quartz crucible;

[0036] (2) Carefully put the polycrystal and dopant into the quartz crucible;

[0037] (3) Close the single crystal furnace, flush the single crystal furnace with argon several times and evacuate it, and check the vacuum leak rate;

[0038] (4) Turn on the argon gas flow, turn on the heater to heat up, and melt the polysilicon;

[0039] (5) After the polycrystal is completely melted, reduce the power of the heater an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com