SBS (stimulated brillouin scattering) modified asphalt and preparation method thereof

A technology of modified asphalt and modifiers, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of increased cost of addition, excessive addition of SBS, unstable sample properties, etc., and achieves a simple and easy process , Save the dosage and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh the raw materials used in the following parts by weight:

[0030] 100 parts heavy asphalt

[0031] Minus three-line furfural extract 6.5 parts of oil

[0032] SBS modifier 3.9 parts

[0033] 1.0 part of polyphosphoric acid

[0034] A preparation method of SBS modified asphalt includes the following steps:

[0035] a. Melt 100 parts of the weighed heavy bitumen at 160°C, and then heat it to 180°C after melting is complete;

[0036] b. Add 3.9 parts of SBS modifier, 6.5 parts of triline furfural extract oil, and 1.0 part of polyphosphoric acid into the melted heavy-duty asphalt at the same time, shear for 2 hours, and add stabilizer for 1 hour to obtain samples;

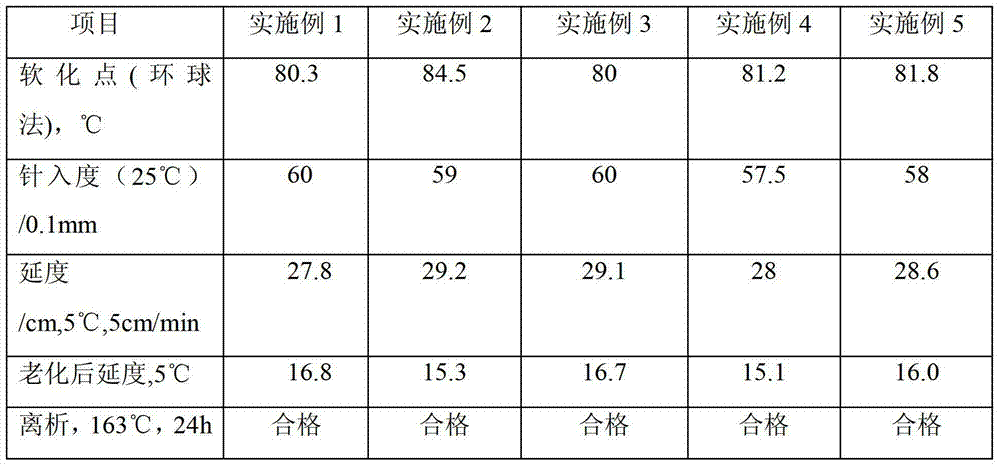

[0037] c. The sample after shearing in step b is stirred for 4 hours at a temperature of 200°C and a rotating speed of 800r / min to make it fully mixed to obtain a finished modified asphalt. The technical indicators of the prepared modified asphalt are shown in the table 2 shown.

Embodiment 2

[0039] Weigh the raw materials used in the following parts by weight:

[0040] 100 parts heavy asphalt

[0041] Minus three-line furfural extract 6.5 parts of oil

[0042] 3.6 parts of SBS modifier

[0043] 1.2 parts of polyphosphoric acid

[0044] A preparation method of SBS modified asphalt includes the following steps:

[0045] a. Melt 100 parts of the weighed heavy duty asphalt at 165℃, and then heat it to 200℃ after the melting is complete;

[0046] b. Add 3.6 parts of SBS modifier, 6.5 parts of triline furfural extraction oil, and 1.2 parts of polyphosphoric acid into the molten heavy-duty asphalt at the same time, shear for 1 hour, and add stabilizer for 0.5 hour to obtain samples;

[0047] c. Stir the sample after shearing in step b at a temperature of 500°C and a rotational speed of 600r / min for 3 hours to make it fully mixed to obtain a finished modified asphalt. The technical indicators of the prepared modified asphalt are shown in the table 2 shown.

Embodiment 3

[0049] Weigh the raw materials used in the following parts by weight:

[0050] 100 parts heavy asphalt

[0051] Minus three-line furfural extract 6.5 parts of oil

[0052] SBS modifier 4.0 parts

[0053] 0.8 part of polyphosphoric acid

[0054] A preparation method of SBS modified asphalt includes the following steps:

[0055] a. Melt 100 parts of the weighed heavy duty asphalt at 168℃, and then heat it to 195℃ after melting;

[0056] b. Add 4.0 parts of SBS modifier, 6.5 parts of triline furfural extraction oil, and 0.8 parts of polyphosphoric acid to the molten heavy-duty asphalt at the same time, shear for 2 hours, and add stabilizer for 2 hours to obtain samples;

[0057] c. The sample after shearing in step b is stirred for 3 hours at a temperature of 1000°C and a rotational speed of 1200r / min to make it fully mixed to obtain a finished modified asphalt. The technical indicators of the prepared modified asphalt are shown in the table 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com