Method for extracting alfalfa polysaccharide by use of complex enzyme

An alfalfa polysaccharide and compound enzyme technology, which is applied in the application, animal feed, animal feed and other directions, can solve the problems of imperfect extraction process of alfalfa polysaccharide, reducing the biological function of polysaccharide, destroying the structure of polysaccharide, etc., so as to promote development and application and reduce extraction time. , the effect of improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. Crush the air-dried or dried alfalfa powder, pass through a 40-mesh sieve, and degrease it with petroleum ether or ether on a Soxhlet extractor until the supernatant is transparent and clear, then dry it at 40°C to obtain defatted grass powder;

[0032] 2. The cellulase, papain and pectinase used in this method were purchased from Sinopharm Chemical Reagent Beijing Co., Ltd., and the enzyme activities were 15000U / g, 6000U / mg and 50U / g respectively.

[0033] 3, get defatted grass powder, by grass powder weight, add 2.5% cellulase, 2.0% papain, 3.0% pectinase, then add disodium hydrogen phosphate-citric acid buffer solution (pH =3.87);

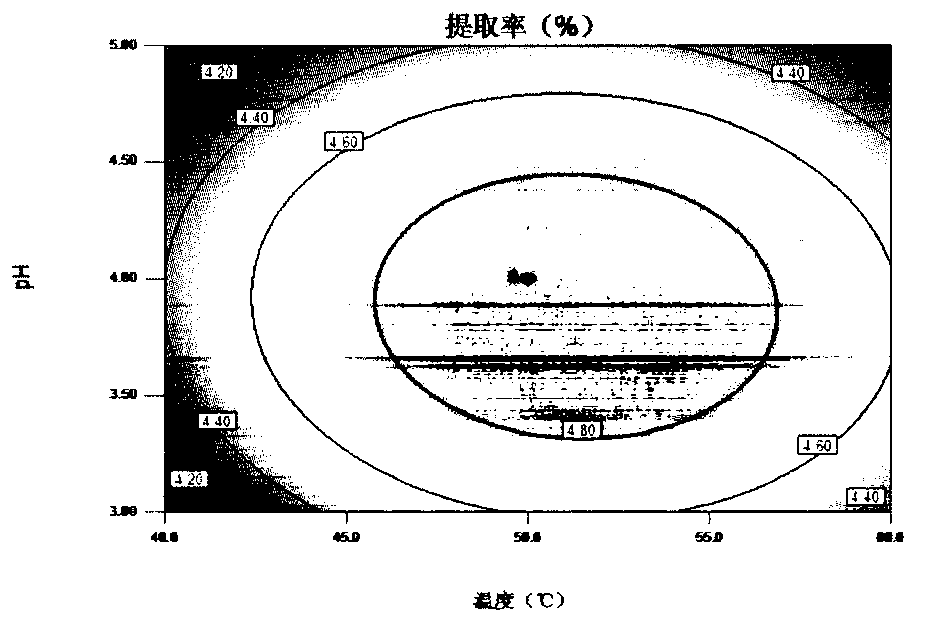

[0034] 4. Put it in a constant temperature water bath, raise the temperature to 52.7°C, then keep the constant temperature, extract for 2.73 hours, stir once every 20 minutes during this period, filter with a vacuum pump after the action, collect the filtrate, and obtain the polysaccharide extract;

[0035] 5. Boil the polysaccharide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com