Coking desulfurization waste liquid pretreatment device

A coking desulfurization waste liquid and pretreatment device technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low removal rate of waste liquid suspension flow, heating decolorization time Long, low adsorption of elemental sulfur, etc., to avoid activated carbon waste, simple structure, low yield of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

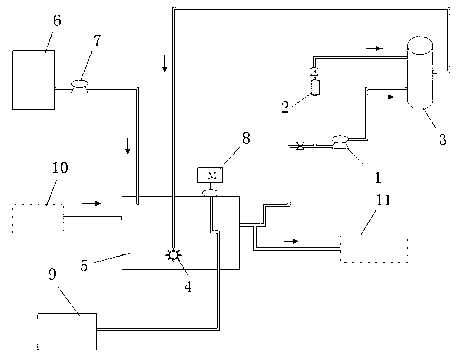

[0014] The present invention consists of a pressurizing pump 1, a water injector 2, an air dissolving tank 3, an aeration head 4, a flotation tank 5, a dosing tank 6, a dosing pump 7, a scum scraper 8 and a scum discharge tank 9.

[0015] The figure shows that the booster pump 1, the water injector 2, the dissolved air tank 3, and the aeration head 4 form the pressurized dissolved air release part, and the air inhaled by the water injector 2 and the desulfurization waste liquid of the booster pump 1 are dissolved in the air. The tank 3 mixes, and then transports the desulfurization waste liquid containing surfactant to the flotation cell 5 for decompression release, and the bubbles absorb the organic matter, suspended solids and metal ions in the waste liquid, and are floated to the surface of the flotation cell 5, Remove scum after generation.

[0016] The structure of the pressurized dissolved air release part is: the liquid inlet pipes of the pressurized pump 1 and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com