Vegetable-sponge-shaped hydrotalcite-like compound and preparation method thereof

A technology of hydrotalcite and loofah pulp, which is applied in the direction of cobalt oxide/cobalt hydroxide, aluminum oxide/aluminum hydroxide, zinc oxide/zinc hydroxide, etc., which can solve the problem of no report of loofah-shaped hydrotalcite, unsuitable for industrial production, and post-production problems. Solve problems such as long process to achieve the effect of unique and uniform shape, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

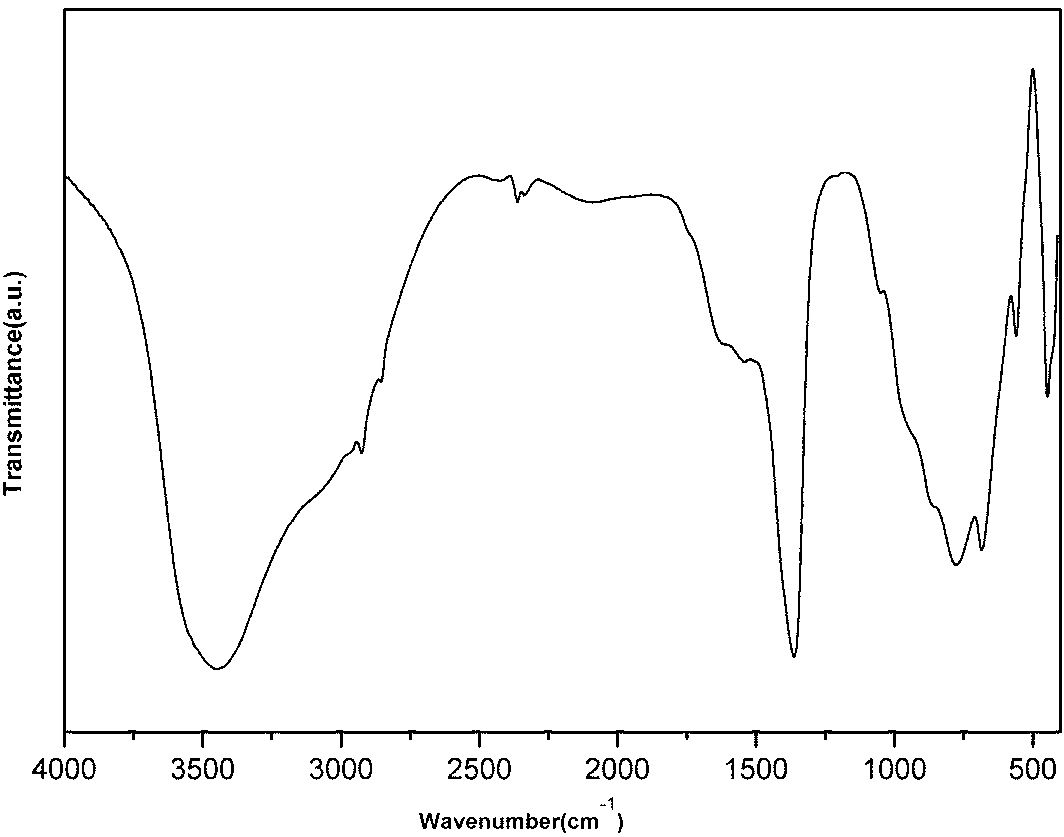

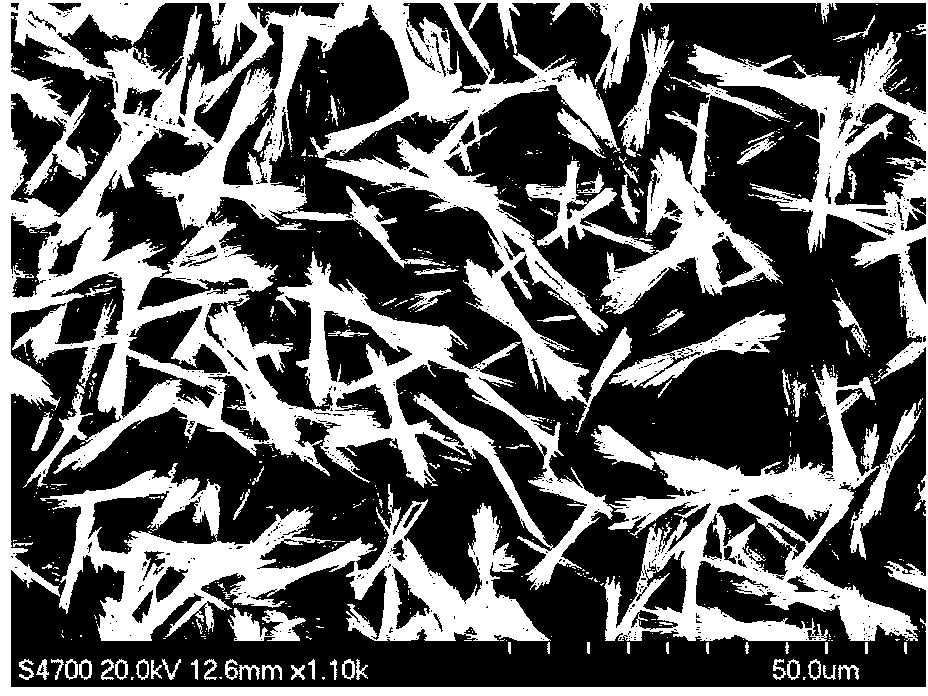

[0024] Step A: 100g Al(NO 3 ) 3 9H 2 O, 40g of urea was mixed in 280mL of deionized water, stirred evenly, and subjected to hydrothermal reaction at 120°C for 24h, the product was washed, filtered, and dried at 80°C to obtain the molecular formula NH 4 [Al(OOH)HCO 3 ] the rod-shaped basic ammonium aluminum carbonate cluster precursor (such as figure 1 shown).

[0025] Step B: Take 5g of basic ammonium aluminum carbonate precursor and disperse it in 250mL of deionized water, slowly add Na 2 CO 3 solution (0.95g dissolved in 100mL deionized water) and Mg(NO 3 ) 2 Solution (4.5g dissolved in 100mL deionized water), heated to 80°C for 10h, the obtained product was washed, filtered, and dried at 70°C to obtain loofah-like Mg / Al-LDHs. The measured BET specific surface area is 90m 2 / g, the average pore diameter is 21.9nm.

Embodiment 2

[0027] Step A: Same as step A in Example 1.

[0028] Step B: Take 5g of basic ammonium aluminum carbonate precursor and disperse it in 250mL of deionized water, slowly add Na 2 CO 3 solution (0.95g dissolved in 100mL deionized water) and Mg(NO 3 ) 2 Solution (4.5g dissolved in 100mL deionized water), heated to 90°C for 9h, the obtained product was washed, filtered, and dried at 70°C to obtain loofah-like Mg / Al-LDHs. The measured BET specific surface area is 94m 2 / g, and the average pore diameter is 21.1nm.

Embodiment 3

[0030] Step A: Same as step A in Example 1.

[0031] Step B: Take 5g of basic ammonium aluminum carbonate precursor and disperse it in 250mL of deionized water, slowly add Na 2 CO 3 solution (3.8g dissolved in 100mL deionized water) and Mg(NO 3 ) 2 Solution (18g Mg(NO 3 ) 2 ·6H 2 O dissolved in 100 mL deionized water), heated to 90 °C for 9 h, the obtained product was washed, filtered, and dried at 70 °C to obtain loofah-like Mg / Al-LDHs. The measured BET specific surface area is 98m 2 / g, the average pore diameter is 21.0nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com