M-MCM-41 mesoporous molecular sieve with high transition metal content and high regularity and preparation method thereof

A M-MCM-41, mesoporous molecular sieve technology, applied in the field of molecular sieves, can solve the problems of low framework metal content and uneven distribution of molecular sieve framework structure, and achieve the effect of expanding the scope of application and large industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

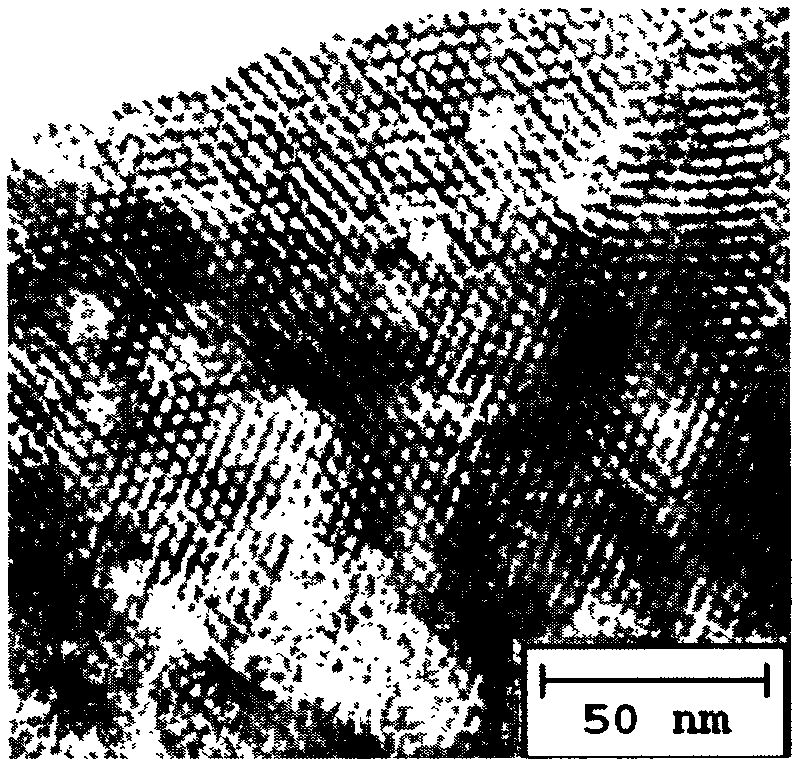

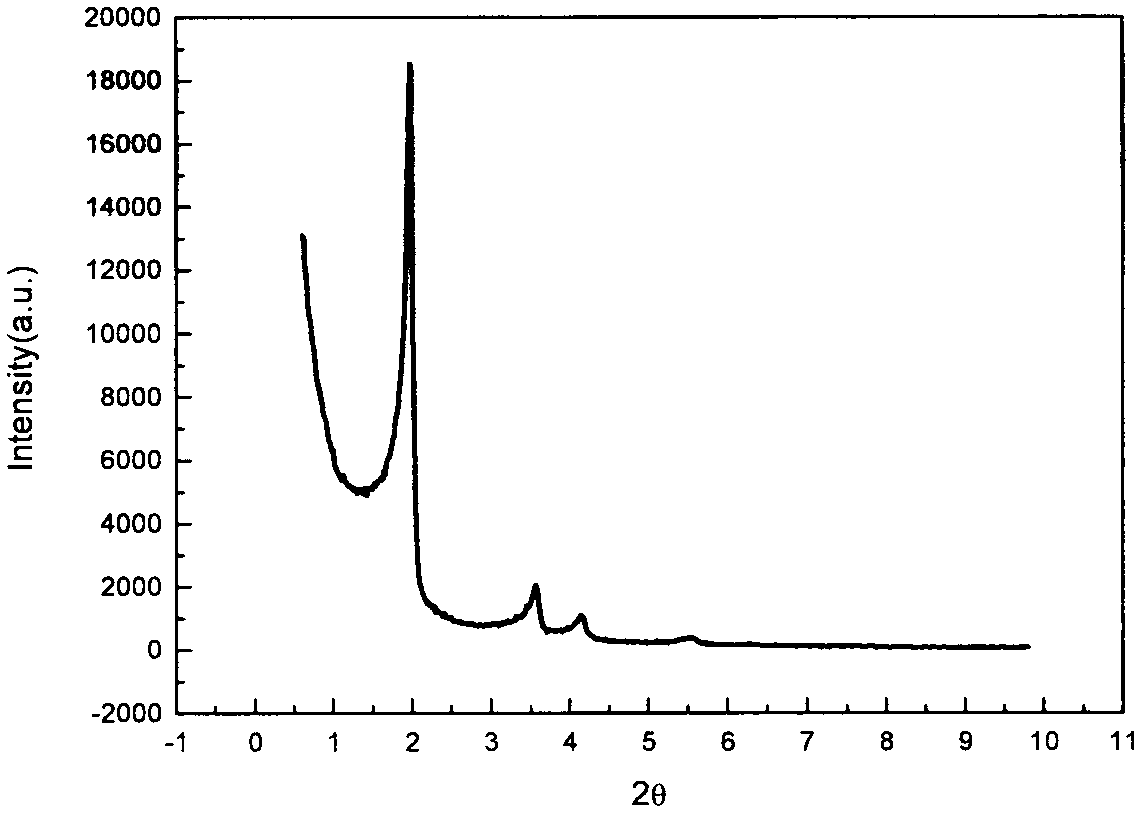

[0025] In a typical embodiment of the present invention, a preparation method of M-MCM-41 mesoporous molecular sieve with high transition metal content and high regularity is provided, the transition metal M is a group consisting of Ni, Co and Cu Any one of them, the preparation method comprises the following steps: (1), preparing the ionic association formed by the complex of transition metal and cationic surfactant [C 16 h 33 (CH 3 ) 3 N] 2 + [M(EDTA)] 2- As a template for the preparation of M-MCM-41 mesoporous molecular sieves, the complexes of transition metals are complexes of transition metals and EDTA, and the cationic surfactant is composed of cetyltrimethylammonium bromide, cetyltrimethylammonium One or more of the group consisting of methyl ammonium chloride, dodecyltrimethylammonium bromide, tetradecyltrimethylammonium bromide and octadecyltrimethylammonium bromide; ( 2), the silicon source, inorganic base, water and the ionic association of step (1) are mixed...

Embodiment 1

[0036] Take by weighing 2.03g nickel nitrate and be dissolved in 10g deionized water, be that the disodium edetate solution of 5wt%-6wt% is added in the described metal salt solution by concentration, stir 0.5 hour, generate metal complex Ni(EDTA ) 2- . Then weigh 5.63g of cetyltrimethylammonium bromide, associate the metal complex with water-soluble cationic surfactant cetyltrimethylammonium bromide, stir for more than 1 hour, and the generated template agent association [C 16 h 33 (CH 3 ) 3 N] 2 + [Ni(EDTA)] 2- As a template for the synthesis of molecular sieves.

[0037] Add 11.31ml tetraethyl orthosilicate dropwise to the prepared template, continue to stir for 1.5 hours, add sodium hydroxide to adjust the pH to 11, and finally add water to make the total amount of water 120ml. It was carried out in a water bath, and after continuous stirring for 3 hours, the obtained gel was transferred into a polytetrafluoroethylene-lined reaction tank for static crystallization...

Embodiment 2

[0039] Weigh 2.02g of cobalt nitrate and dissolve it in 10g of deionized water, add a disodium edetate solution with a concentration of 5wt%-6wt% into the metal salt solution, stir for 0.5 hour, and generate the metal complex Co(EDTA ) 2- . Then weigh 5.63g of cetyltrimethylammonium bromide, associate the metal complex with water-soluble cationic surfactant cetyltrimethylammonium bromide, stir for more than 1 hour, and the generated template agent association [C 16 h 33 (CH 3 ) 3 N] 2 + [Co(EDTA)] 2- As a template for the synthesis of molecular sieves.

[0040] Add 11.31ml tetraethyl orthosilicate to the prepared template, continue to stir for 1.5 hours, add sodium hydroxide to adjust the pH to 11, and finally add water to make the total amount of water 120ml. The above synthesis process is carried out in a water bath at 50°C To proceed, after 3 hours of continuous stirring the resulting gel was transferred into a Teflon-lined reaction tank for static crystallization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com