Fe-SAPO-34 molecular sieve with high skeleton ion content and preparation method thereof

A SAPO-34, fe-sapo-34 technology, applied in the field of molecular sieve preparation, can solve the problems of low heteroatom metal content, low catalytic activity, etc., achieve high metal content, high specific surface area, and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

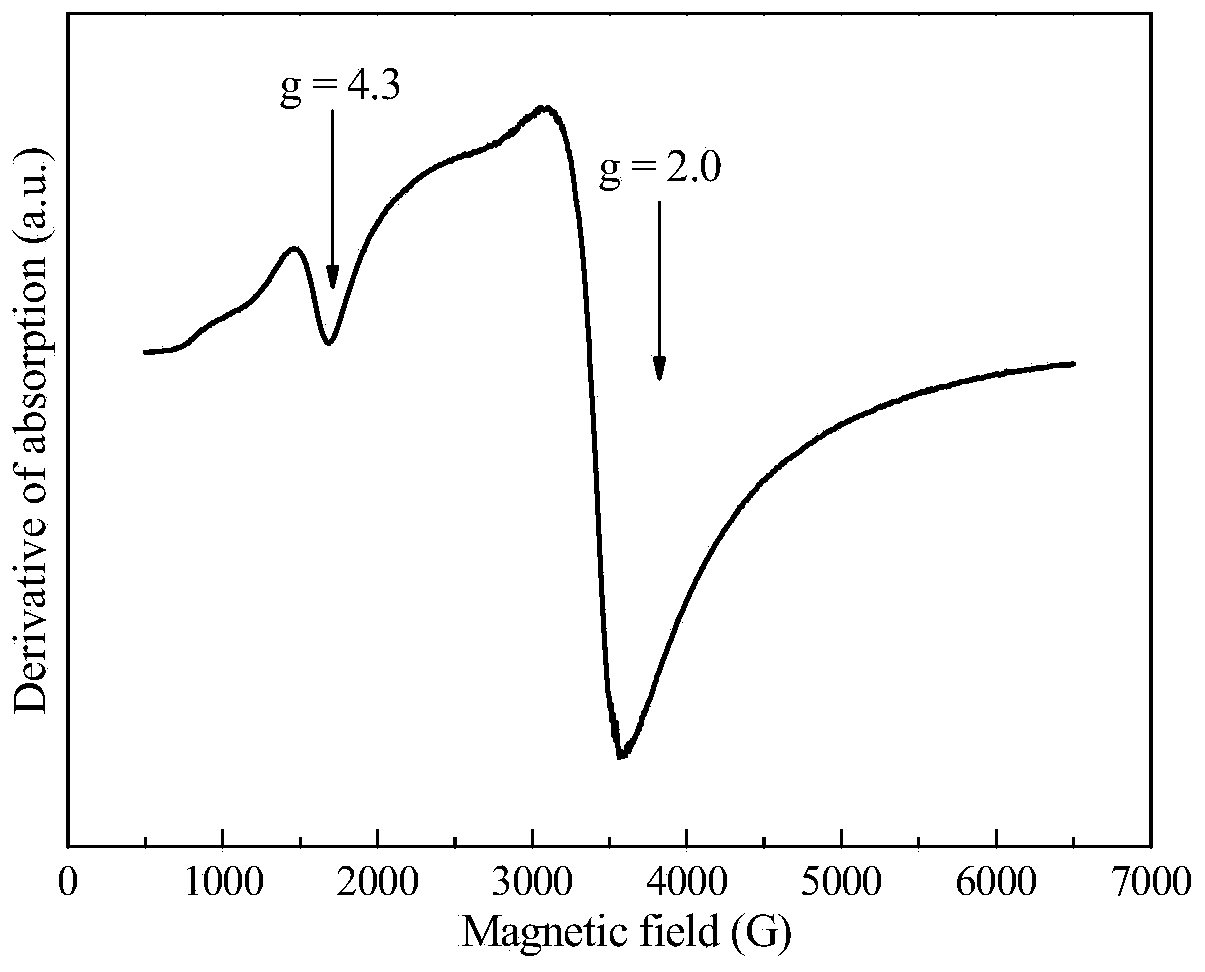

Image

Examples

Embodiment 1

[0028] Add 10g of phosphoric acid and 10g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 minutes, 8 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized under autogenous pressure of 160° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template agent.

Embodiment 2

[0030] Add 10g of phosphoric acid and 12.1g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 min, 10 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized at an autogenous pressure of 160° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C·min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template agent.

Embodiment 3

[0032] Add 8g of phosphoric acid and 12.1g of ethyl orthosilicate to 60ml of deionized water, stir for 15min, then add 11g of K 4 Fe(CN) 6 After continuing to stir for 60 min, 10 ml of diethylamine was added, and after 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and crystallized under autogenous pressure of 180° C. for 72 hours. Then the sample was suction-filtered, washed with deionized water until neutral, and dried at 100°C for 6 hours. at 1°C·min -1 The temperature was programmed to 550°C, and the temperature was kept for 5 hours to remove the templating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com