Metal or metal oxide loaded mesoporous carbon material and preparation method thereof

A technology for supporting metals and mesoporous carbon, applied in nanotechnology, nanocarbon, nanotechnology, etc. for materials and surface science, to achieve the effects of size control, low equipment requirements, and broadened uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

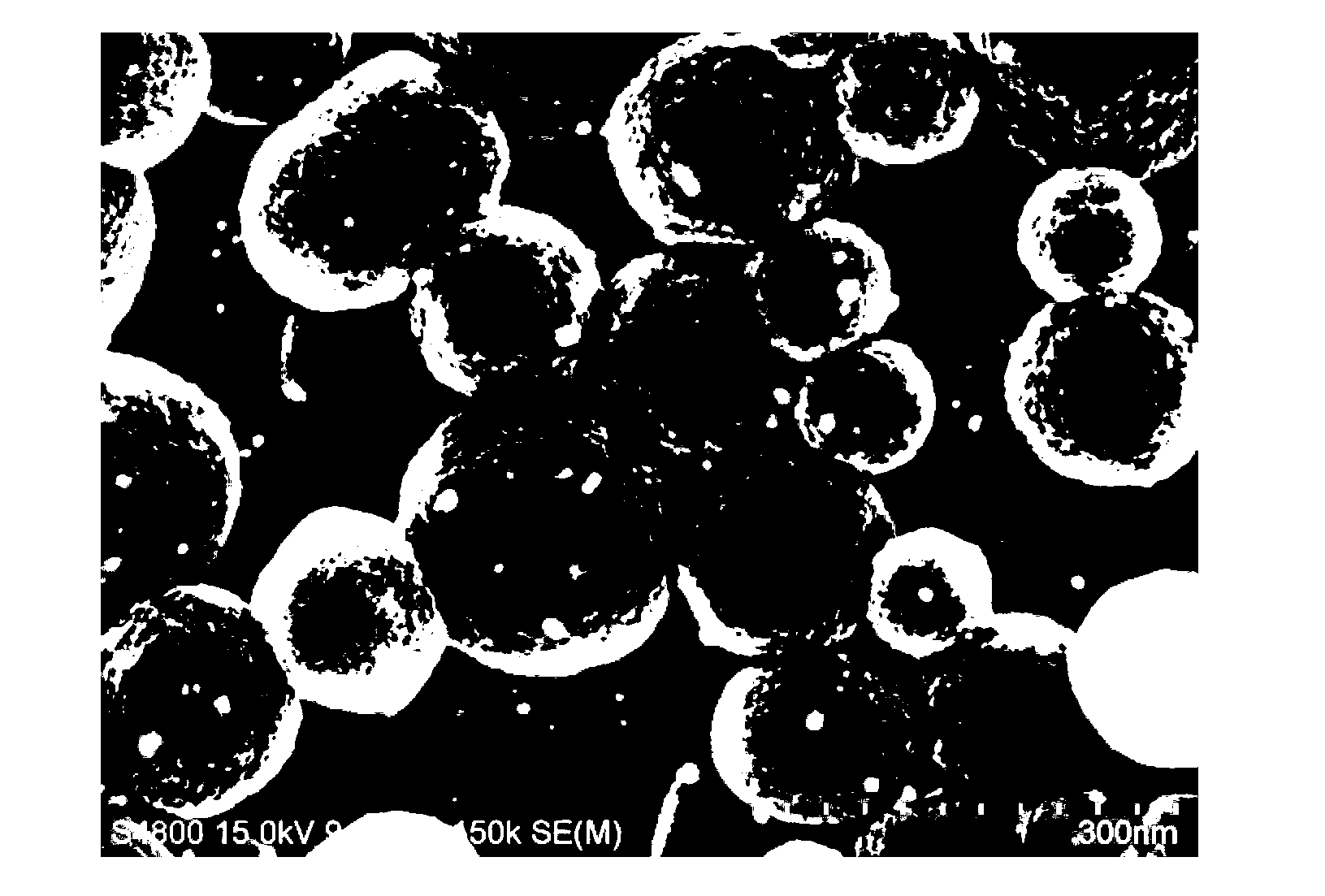

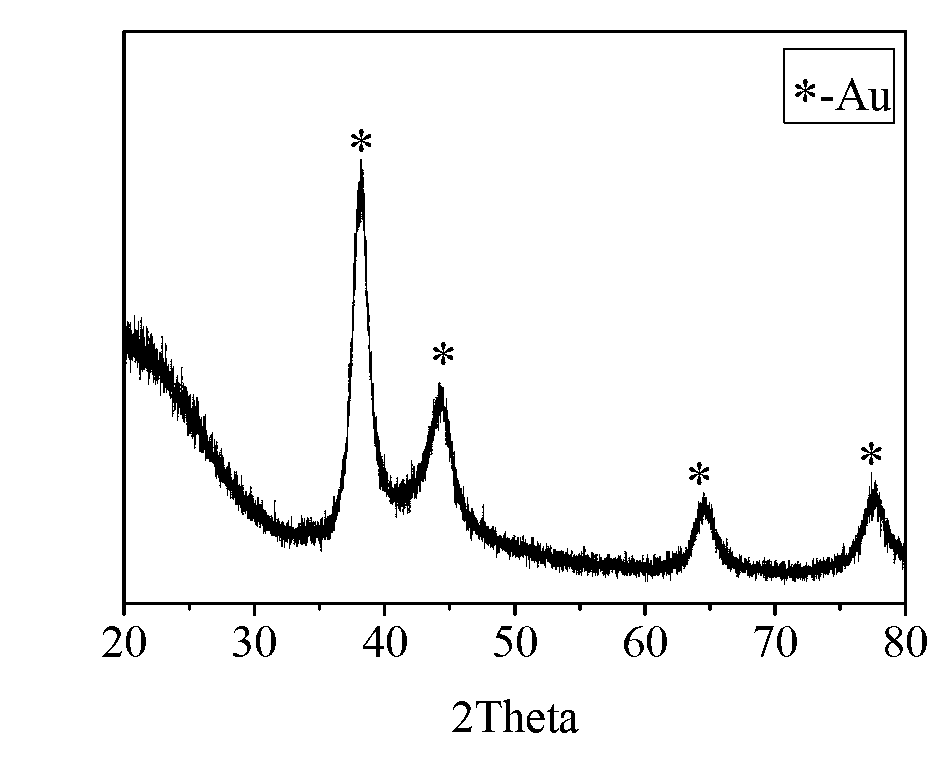

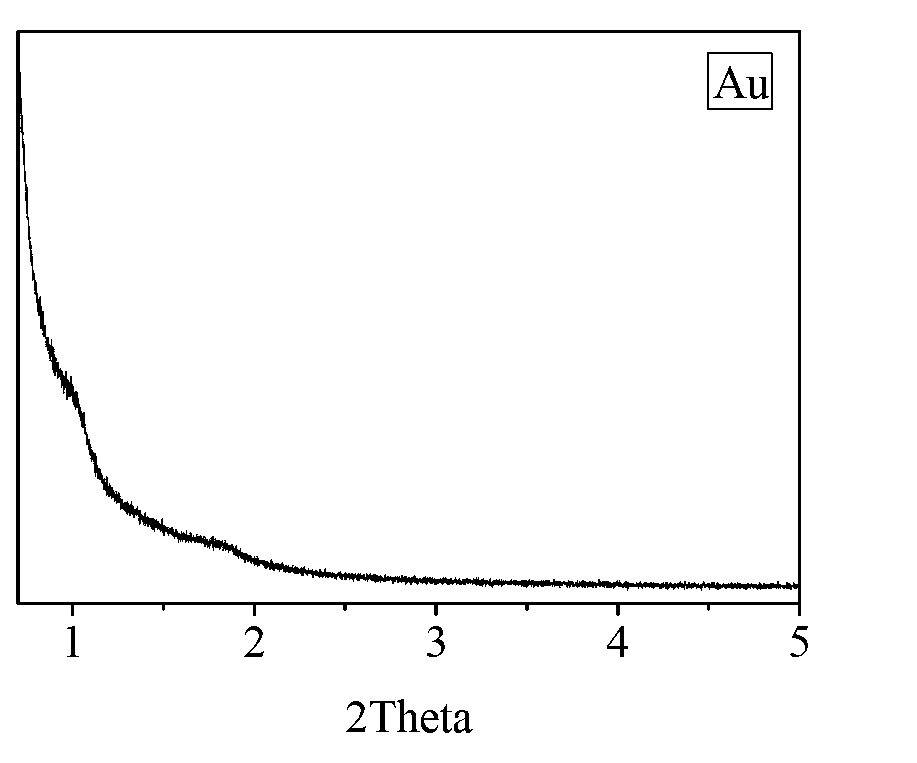

[0038] Example 1: Preparation of ordered mesoporous carbon materials loaded with Au nanoparticles

[0039] Mix 1.6g of phenol, 5.6mL of formaldehyde, 40mL of NaOH solution with a concentration of 0.1mol / L, 2.56g of F127, and 130mL of water, heat and stir in a water bath at 62°C for 20h to prepare a precursor solution. Get this solution 12mL, 0.6mL concentration be that the chloroauric acid solution of 10g / L, 38mL water are placed in the autoclave of 100mL volume, and this autoclave is airtight, is warming up to 130 ℃ and keeps 24h. After cooling to room temperature, it was ultrasonically cleaned three times with water and ethanol, each time for 15 minutes, and dried at 60°C for 3 hours. After drying, at N 2 The ordered mesoporous carbon materials loaded with Au nanoparticles were obtained by calcination at 700°C for 3 h under atmosphere.

[0040] After structural characterization, the obtained ordered mesoporous carbon material loaded with Au nanoparticles was measured by ni...

Embodiment 2

[0043] Example 2 Preparation of Ag nanoparticles-loaded ordered mesoporous carbon material

[0044] Mix 1.0 g of phenol, 3.5 mL of formaldehyde, 40 mL of NaOH solution with a concentration of 0.1 mol / L, 1.6 g of F127, and 130 mL of water, and heat and stir at 63°C for 18 hours to prepare a precursor solution. Take this solution 12mL, 2mL concentration is the silver nitrate solution of 1.6g / L and 36mL water and place in the autoclave of 100mL volume, this autoclave is airtight, is heated up to 130 ℃ and keeps 20h. After cooling to room temperature, it was washed with ethanol ultrasonically for 3 times, then with water for 2 times, and dried at 50°C for 5 hours. After drying, at N 2 The ordered mesoporous carbon materials loaded with Ag nanoparticles were obtained by calcination at 700°C for 3 h under atmosphere.

[0045]After structural characterization, the ordered mesoporous carbon material loaded with Ag nanoparticles was measured by nitrogen adsorption-desorption experime...

Embodiment 3

[0048] Example 3, preparation of ordered mesoporous carbon material loaded with Pt nanoparticles

[0049] Mix 1.2 g of phenol, 4.2 mL of formaldehyde, 40 mL of NaOH solution with a concentration of 0.1 mol / L, 1.92 g of F127, and 130 mL of water, heat and stir in a water bath at 61 °C for 24 h to prepare a precursor solution. Take 12mL of the precursor solution, 0.6mL of chloroplatinic acid solution with a concentration of 10g / L and 38mL of water in a 100mL autoclave. The autoclave is sealed and heated to 130°C for 24h. After cooling to room temperature, ultrasonically wash with ethanol and water three times each, and dry at 40°C for 6h. After drying, at N 2 The ordered mesoporous carbon materials loaded with Pt nanoparticles were obtained by calcination at 700°C for 3 h under atmosphere.

[0050] After structural characterization, the ordered mesoporous carbon material loaded with Pt nanoparticles was measured by nitrogen adsorption-desorption experiments with a pore diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com