Screening method for lithium-ion battery consistency

A technology of a lithium-ion battery and a screening method, which is applied in the field of battery testing, can solve the problems of battery over-discharge, large differences in the consistency of single cells, and over-charging, and achieves the effect of improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

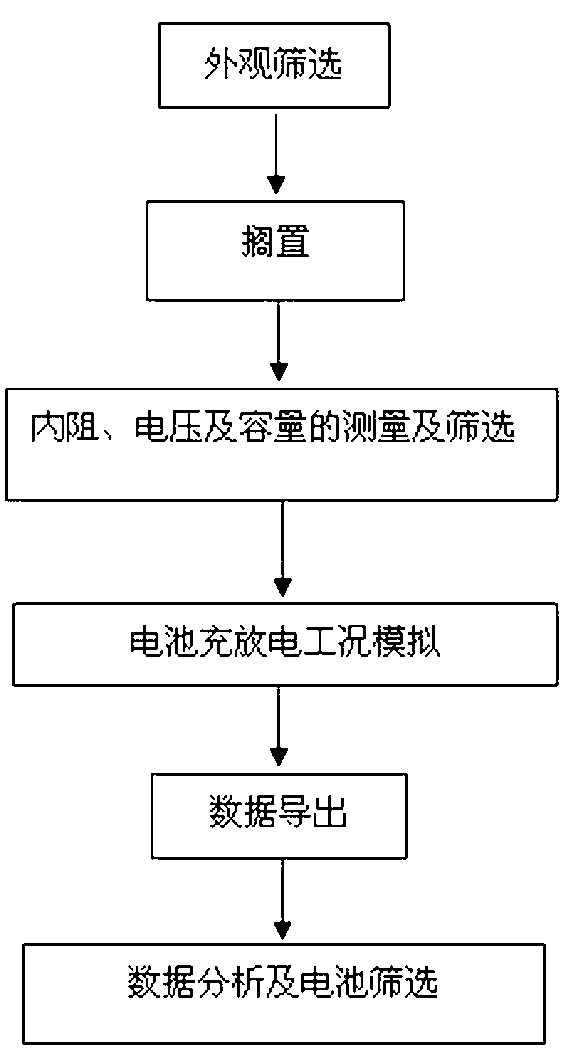

[0025] Method concrete steps of the present invention are as follows:

[0026] Screen out lithium-ion single batteries produced under the same conditions, that is, the raw material composition of the battery and the preparation process of the battery must be consistent;

[0027] Screen the appearance of the battery: the battery must have no flatulence, no leakage, no scratches on the surface, and the appearance and size are qualified, and the batteries with qualified appearance are screened out;

[0028] Put the screened qualified batteries at room temperature at 20-30°C for a preset time: 14-28 days;

[0029] According to the capacity, internal resistance and voltage drop of the single battery under different environments of high temperature: 40-60 °C, low temperature: -40-0 °C or normal temperature: 20-30 °C, statistics and screening are carried out;

[0030] Measure the capacity, internal resistance and voltage drop of the battery to be screened under different temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com