Wire strand cooling spray nozzle for polyester chip production equipment

A technology for production equipment and cooling nozzles, which is applied to spray devices, spray devices, etc., can solve the problems that steel nozzles are easy to fall and slide into the pelletizing chamber, damage the rotary cutter, and cannot concentrate water pressure, etc. Improves corrosion resistance and does not fall easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

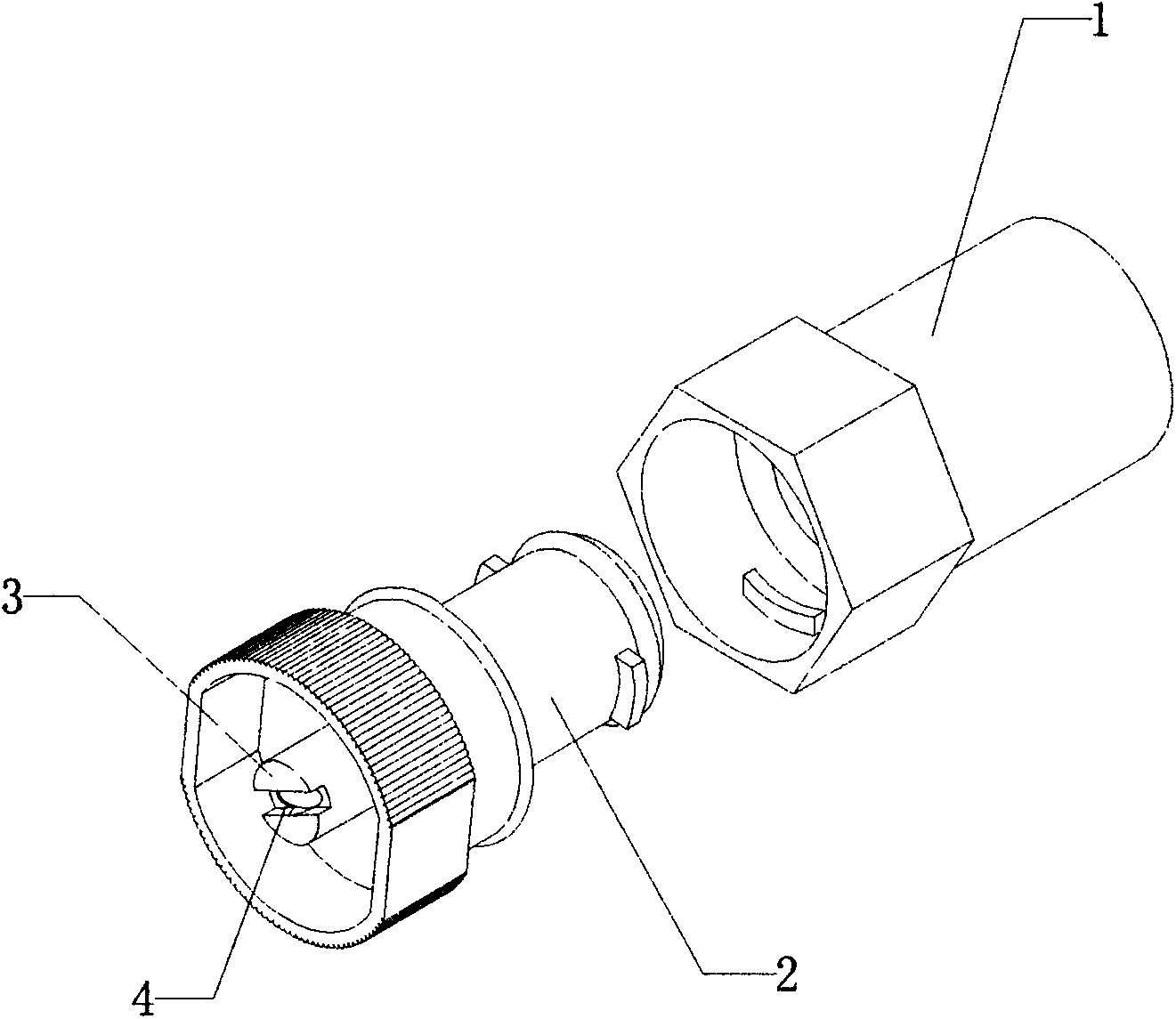

[0010] like figure 1 As shown, a strand cooling nozzle for polyester chip production equipment includes a riser seat 1, the right end of the riser seat 1 is provided with a water inlet, and the left end of the riser seat 1 is connected to the riser body through a buckle 2. There is a riser 3 inside the riser main body 2, and a straight nozzle 4 is set on the left end surface of the riser 3.

[0011] The wire strand cooling nozzle of the present invention has a simple structure, which is beneficial to pre-tightening and is not easy to drop. The whole is made of plastic steel material, and the rotary knife will not be damaged if it enters the cutting chamber by mistake. Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com