Affinity adsorption material for treating hyperbilirubinemia and preparation method thereof

A technology for hyperbilirubinemia and adsorption materials, applied in the field of bioseparation engineering, can solve the problems of difficult clinical application of materials, complicated preparation methods of cross-linked macroporous chitosan microspheres, etc. Mild conditions and efficacy in the treatment of hyperbilirubinemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

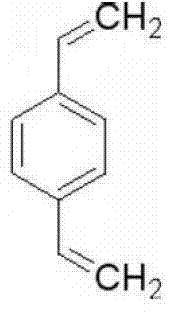

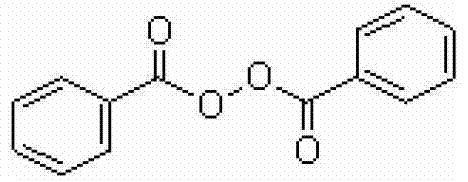

[0023] Step 1: Mix 1.5g AA and 10.5g St, add 0.96g DVB, 0.12g BPO in sequence, and stir well;

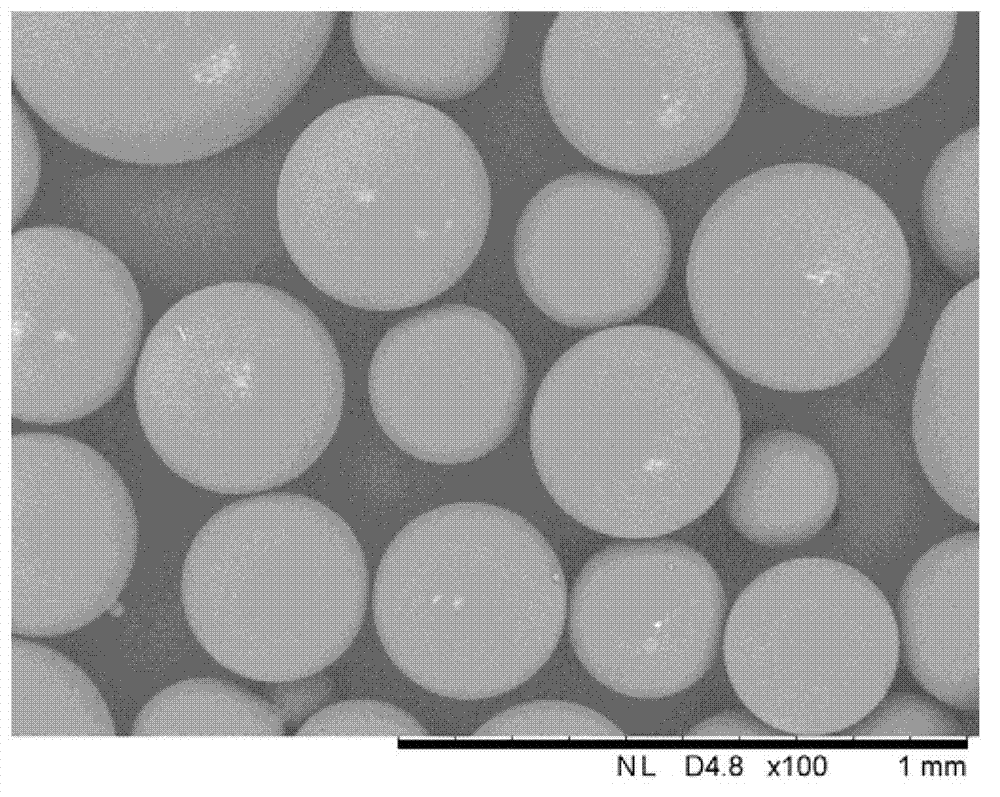

[0024] Step 2: Add the mixed solution in step 1 to 48 g of deionized water containing 0.5 g of PVA, stir mechanically at 600 rpm, react at 75°C for 4 hours, and cure at 90°C for 2 hours to obtain poly(styrene-acrylic acid) microspheres;

[0025] Step 3: Disperse the poly(styrene-acrylic acid) microspheres in step 2 in deionized water, adjust the concentration to 100g / L, and add 2.95g of NHS;

[0026] Step 4: Add 4.61 g of EDC in Step 3 and stir at room temperature for 8 h. The obtained product was repeatedly washed with deionized water, suction filtered, and vacuum-dried to constant weight to obtain activated poly(styrene-acrylic acid) microspheres;

[0027] Step 5: Disperse the activated poly(styrene-acrylic acid) microspheres in step 4 in phosphate buffer solution (pH=7.4), and adjust the concentration to 100g / L. Add 2.4g HAS and stir at room temperature for 12h. The obtained p...

Embodiment 2~7

[0029] The steps are the same as in Example 1, changing the amount of raw materials, cross-linking agent, initiator, stabilizer, dehydrating agent, catalyst, solvent, changing the conditions such as reaction temperature, reaction time, mechanical stirring speed, etc., to obtain human serum albumin-immobilized poly (Styrene-acrylic acid) microspheres, see Table 1 for steps 1 and 2, and see Table 2 for steps 3 and 5.

[0030] Table 1

[0031]

[0032] Table 2

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com