Preparation method of raw dendrobium officinale pulp beverage

A technology of dendrobium candidum and beverage, which is applied in the field of preparation of dendrobium candidum puree beverage, can solve the problems such as the loss of efficacy of fresh juice of dendrobium candidum, and achieve the effects of rich functional components, increased extraction rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

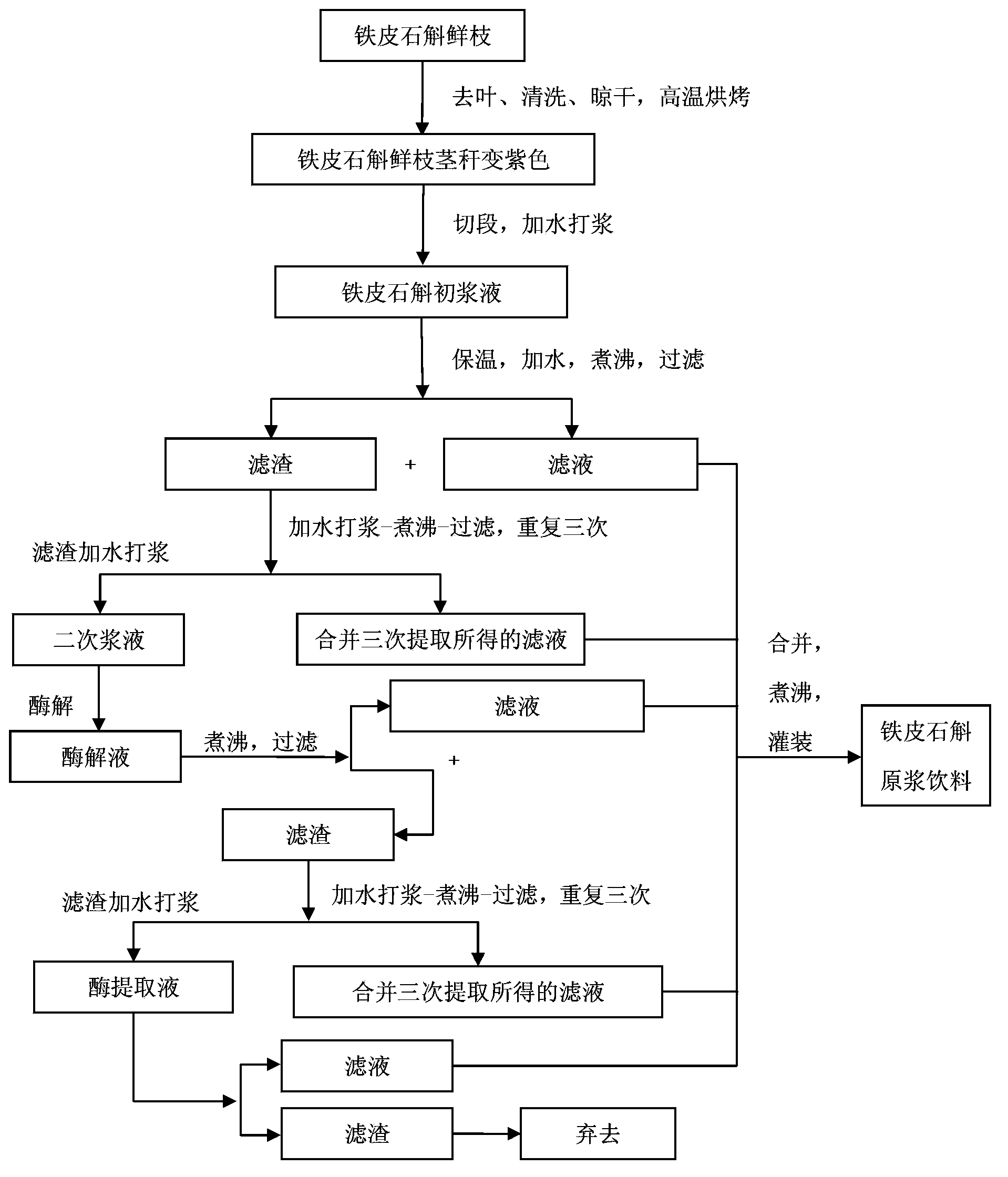

Method used

Image

Examples

Embodiment 1

[0036] (1) Remove the leaves of fresh Dendrobium officinale, wash and dry, bake at 85°C for 40 minutes, and cut into 0.1cm-long stems; take the stems of Dendrobium candidum with a material-to-water ratio of 1:6 and clean water , beating to obtain initial slurry;

[0037] (2) Heat the initial slurry at 55°C for 60 minutes; add 8 times the amount of water of Dendrobium candidum raw materials after heat preservation, boil for 3 minutes, filter, and save the filtrate; Double the amount of water, beating to obtain secondary slurry;

[0038] (3) Add cellulase to the secondary slurry, the addition amount is 5U / g Dendrobium candidum raw material; enzymolyze at pH about 5.0 and 48°C for 20min to obtain enzymatic hydrolyzate;

[0039] (4) Boil the enzymolysis solution for 3 minutes, filter, and save the filtrate; repeat "adding water and beating-boiling-filtering" to the filter residue three times, take the filter residue and add 3 times the amount of water, beat, filter, and take the ...

Embodiment 2

[0045] (1) Remove the leaves of fresh Dendrobium officinale, wash and dry, bake at 95°C for 15 minutes and cut into 0.2cm-long stems; take the stems of Dendrobium candidum with a material-to-water ratio of 1:5 and clean water , beating to obtain initial slurry;

[0046](2) Heat the initial slurry at 50°C for 30 minutes; add 10 times the amount of water of Dendrobium candidum raw material after heat preservation, boil for 5 minutes, filter, and save the filtrate; Double the amount of water, beating to obtain secondary slurry;

[0047] (3) Add cellulase to the secondary slurry, the addition amount is 10U / g Dendrobium candidum raw material; enzymolyze at pH about 5.0 and 50°C for 30min to obtain enzymatic hydrolyzate;

[0048] (4) Boil the enzymolysis solution for 5 minutes, filter, and save the filtrate; repeat "adding water and beating-boiling-filtering" to the filter residue three times, take the filter residue and add 4 times the amount of water, beat, filter, and take the f...

Embodiment 3

[0051] (1) Remove the leaves of fresh Dendrobium officinale, wash and dry them, bake them at 90°C for 30 minutes, and then cut them into 0.8cm-long stems; take the stems of Dendrobium candidum with a material-to-water ratio of 1:7 and clean water , beating to obtain slurry;

[0052] (2) Heat the initial slurry at 50°C for 120 minutes; add 9 times the amount of water of Dendrobium candidum raw material after heat preservation, boil for 5 minutes, filter, and save the filtrate; Double the amount of water, beating to obtain secondary slurry;

[0053] (3) Add cellulase to the secondary slurry, the addition amount is 15U / g Dendrobium candidum raw material; enzymolyze at pH 5.0 and 52°C for 10min to obtain enzymatic hydrolyzate;

[0054] (4) Boil the enzymolysis solution for 5 minutes, filter, and save the filtrate; repeat "adding water and beating-boiling-filtering" to the filter residue three times, take the filter residue and add 5 times the amount of water, beat, filter, and ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com