A printed circuit board and its processing method

A technology for printed circuit boards and circuits, which is applied to printed circuit components, and removes conductive materials by chemical/electrolytic methods. It can solve problems that affect signal accuracy, side erosion, and inability to protect, so as to ensure accuracy. , avoid side erosion phenomenon, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

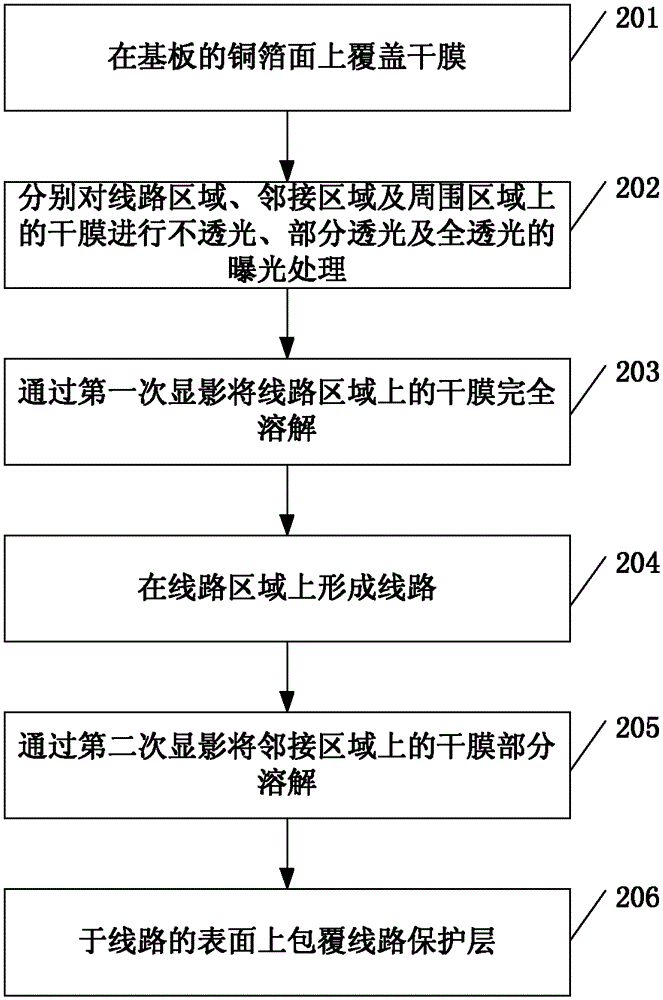

[0025] refer to figure 2 , the PCB processing method of the embodiment of the present invention mainly includes:

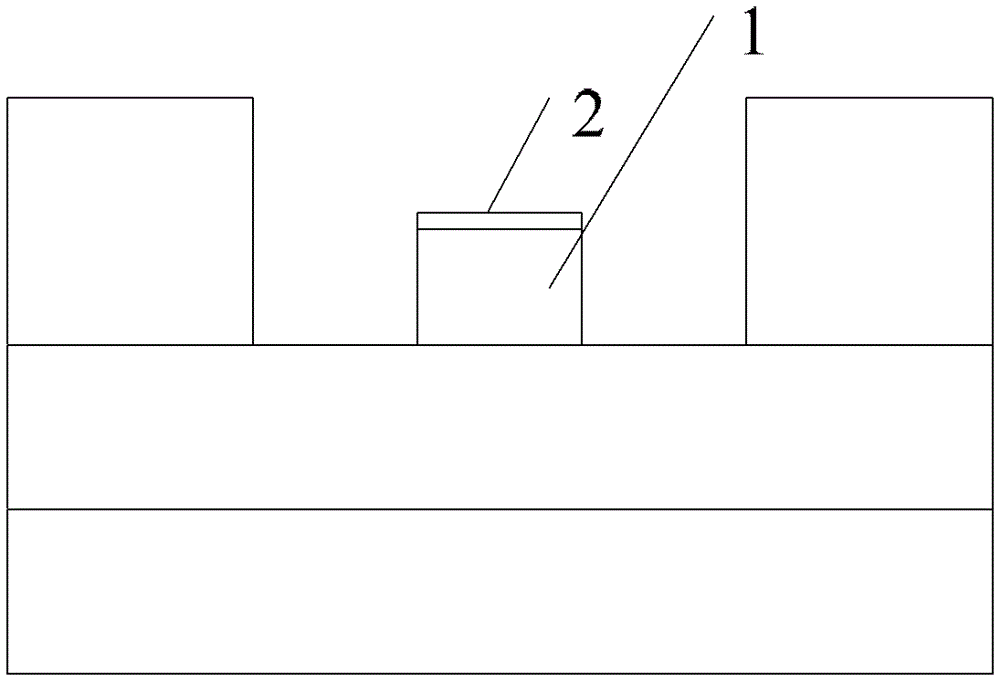

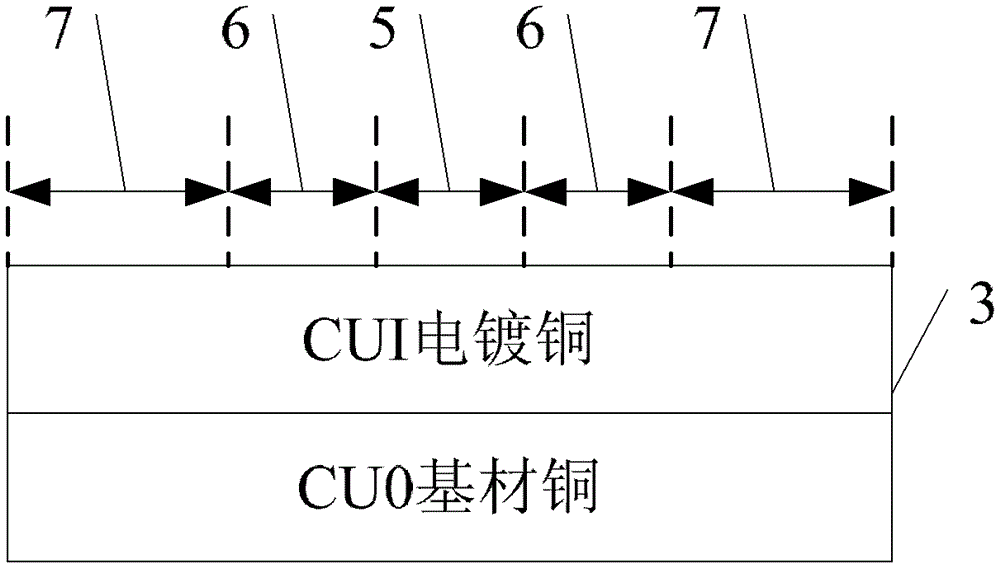

[0026] 201, covering the dry film 4 on the copper foil surface of the substrate 3, the copper foil surface includes the line area 5 and the non-line area for setting the line 1, and the non-line area includes the adjacent area 6 adjacent to the line area 5 and the surrounding area 7. Specifically, the circuit area 5, the adjacent area 6 and the surrounding area 7 on the copper foil surface can be as follows image 3 As shown, the structure formed after the substrate 3 covers the dry film 4 can be as follows Figure 4 shown;

[0027] 202. Perform opaque, partially transparent, and fully transparent exposure treatments on the dry film on the circuit area 5, the adjacent area 6, and the surrounding area 7 respectively. Specifically, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com