Automatic dismantling and separating device for waste dry cell and dismantling and separating method

A separation device, dry battery technology, applied in battery recycling, solid waste removal, recycling technology and other directions, can solve the problems of dismantling hazards, low manual dismantling efficiency, inability to meet large-scale dismantling, separation and recycling, etc. High degree of automation, improve work efficiency and separation effect, and solve the effect of incomplete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

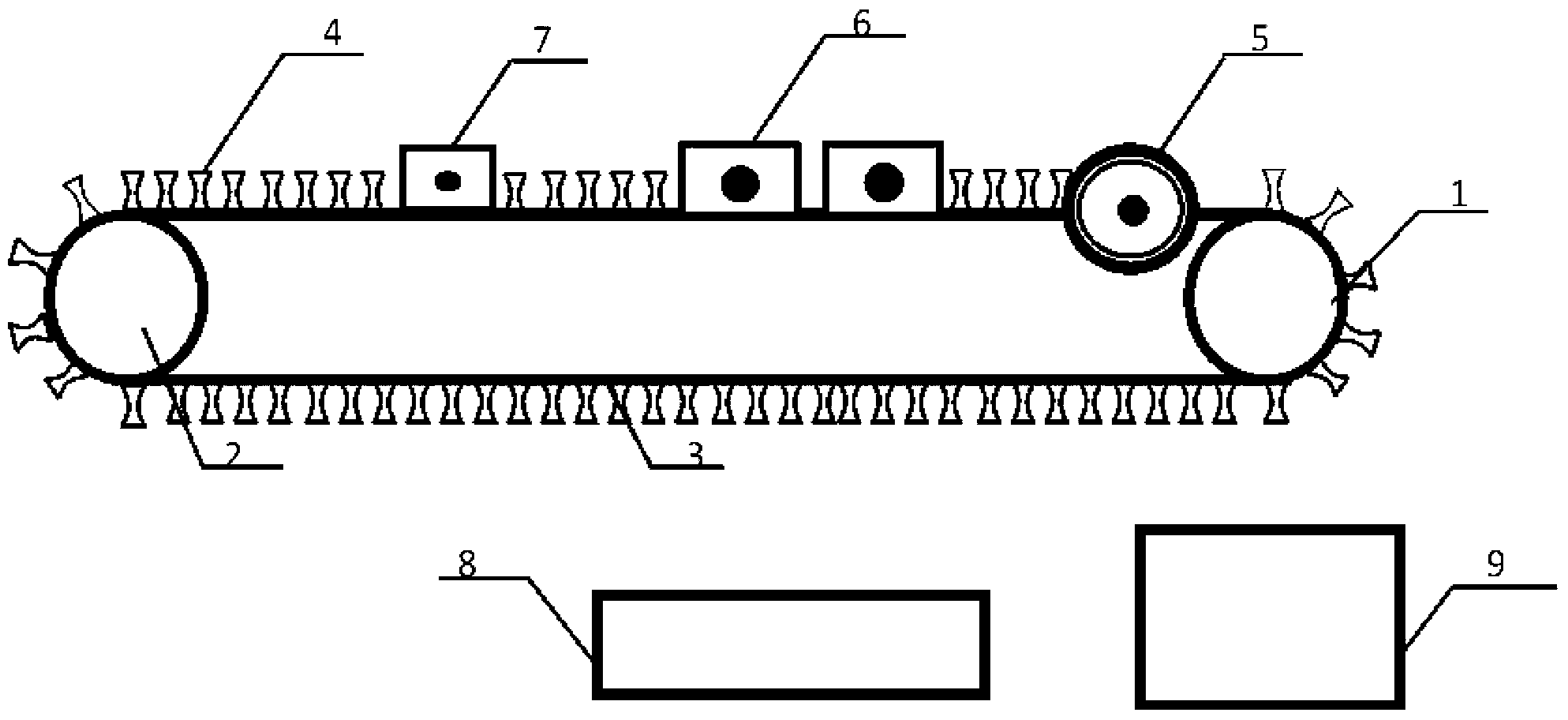

[0031] See attached Figure 1 ~ Figure 2 The automatic dismantling and separation device for waste dry batteries includes two rollers, a conveyor belt 3, a grinding wheel set 5, a striker 6, a cutter 7 and a vibrating screen 8; the surface of the conveyor belt 3 is provided with a plurality of rubber partitions evenly spaced 4. The two rollers include a first roller 1 and a second roller 2, wherein the first roller 1 is a driving roller for driving the conveyor belt 3 to move, and the second roller 2 is a driven roller; the grinding wheel set is arranged on On the conveyor belt 3 and located at one end close to the first drum 1, the grinding wheel set 5 includes a first grinding wheel and a second grinding wheel, and the first grinding wheel and the second grinding wheel are respectively located on both sides of the conveyor belt 3; On the first side of the conveyor belt 3, a cutter 7 is arranged on the conveyor belt 3 and at an end close to the second drum 2; The striker 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com