Ultrasonic phased array detection method of steel box beam U-rib angle welding seam

An ultrasonic phased array and detection method technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., can solve the problem of poor quantitative accuracy, low accuracy, fillet welding Seam difficulty and other problems, to achieve the effect of welding quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

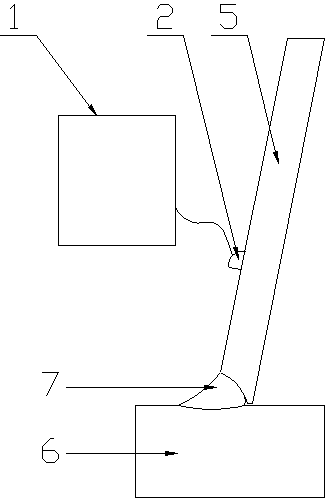

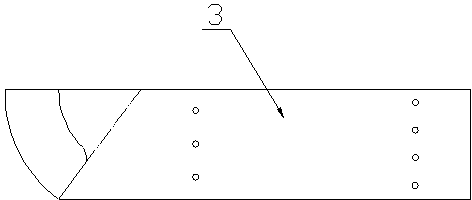

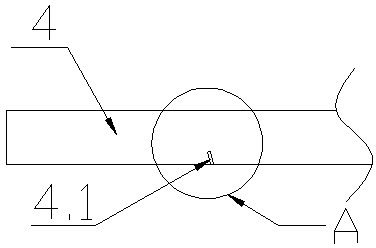

[0040] see Figure 1-8 , the present invention relates to an ultrasonic phased array detection method for steel box girder U rib fillet welds, the detection device of the method comprises an ultrasonic phased array detector 1, a phased array probe 2, a CSK-IA test block 3, and a comparison Test block 4, U-rib web 5, panel 6 and fillet weld 7, the lower end of the U-rib web 5 is welded to the panel 6 to form fillet weld 7, and the phased array probe 2 is arranged on the U-rib The outer side of the web 5 is used to detect the penetration depth and internal defects of the fillet weld 7 , and the ultrasonic phased array detector 1 is connected to the phased array probe 2 .

[0041] The comparative test block 4 is a flat chute test block of the same material as the U rib web 5, and there are 2 test blocks in a group. Thickness, the first chute 4.1 and the second chute 4.2 are respectively opened on the plane of each comparison test block 4 from the end 30mm, the chute is inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com