Compression fatigue testing device and method for low-speed impacted composite material laminate

A low-speed impact and fatigue test technology, applied in the field of fatigue test, can solve the problem of direct application of composite laminate test pieces to compression fatigue test, etc., and achieve good neutrality effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

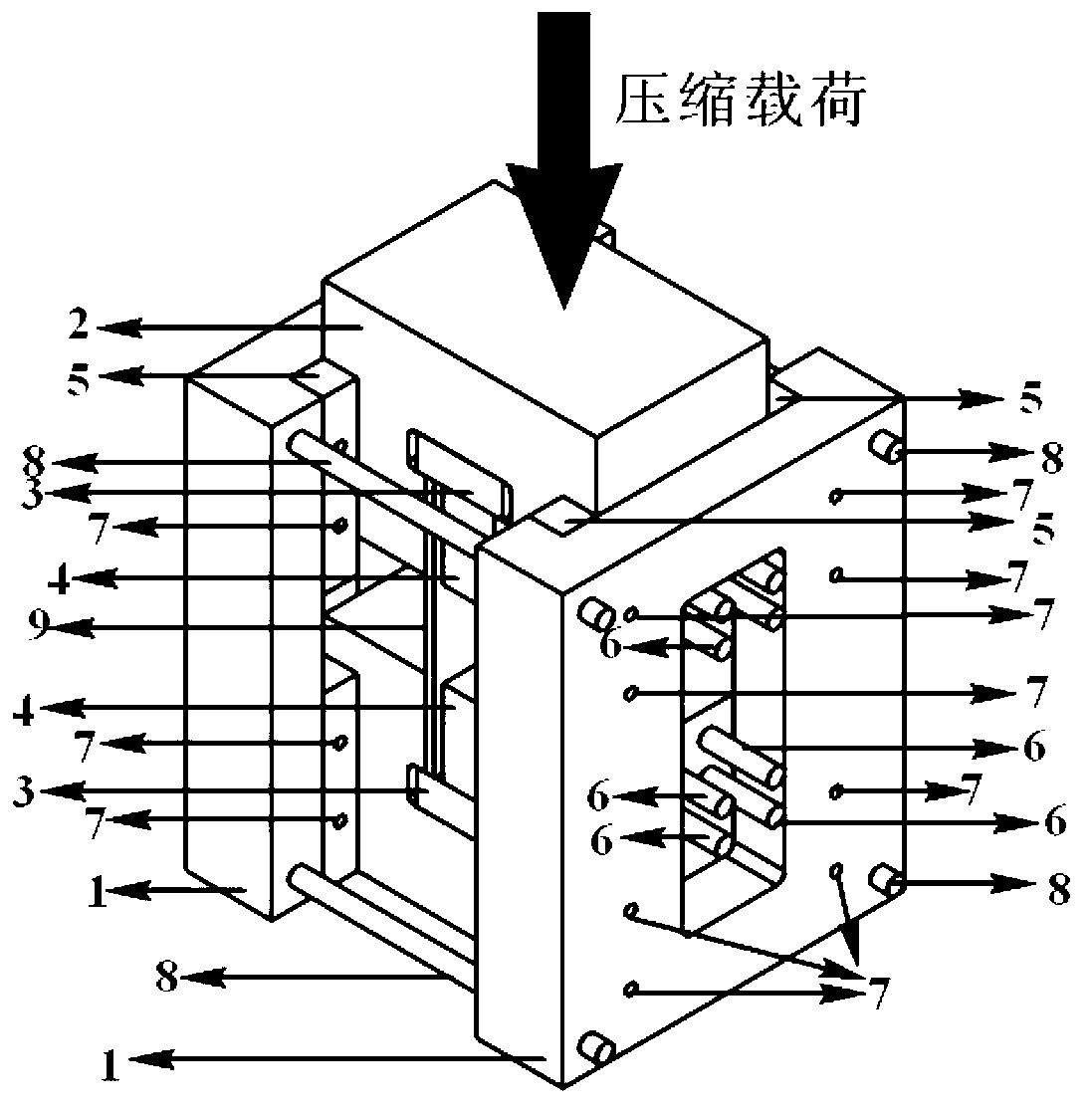

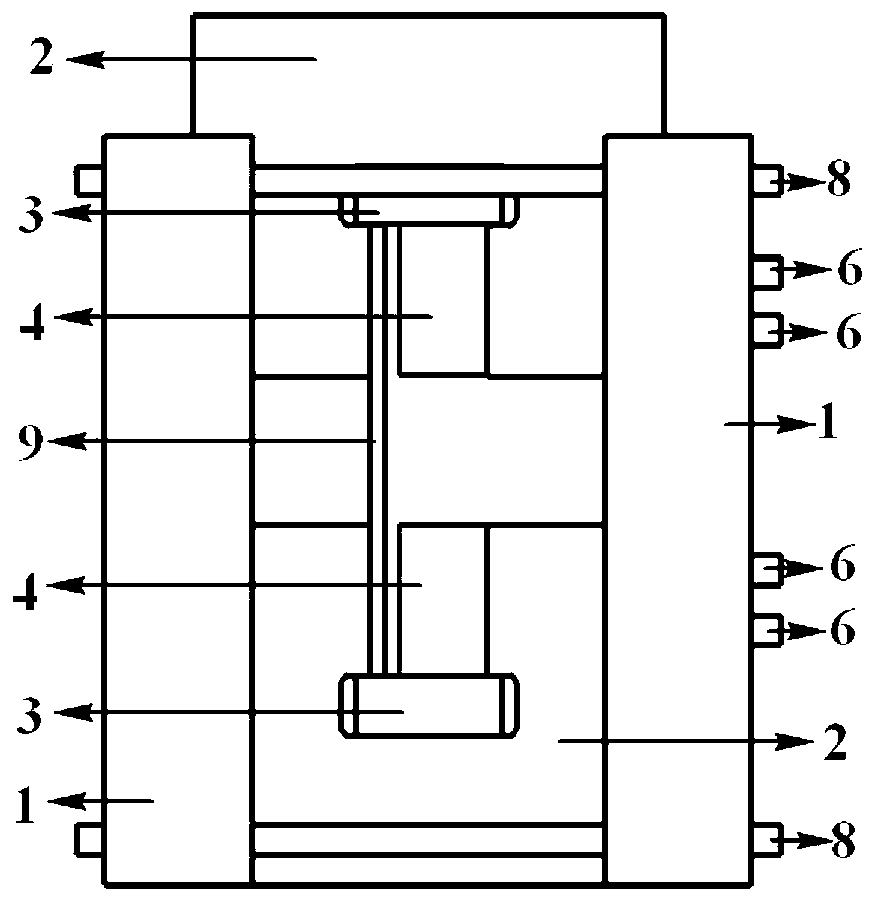

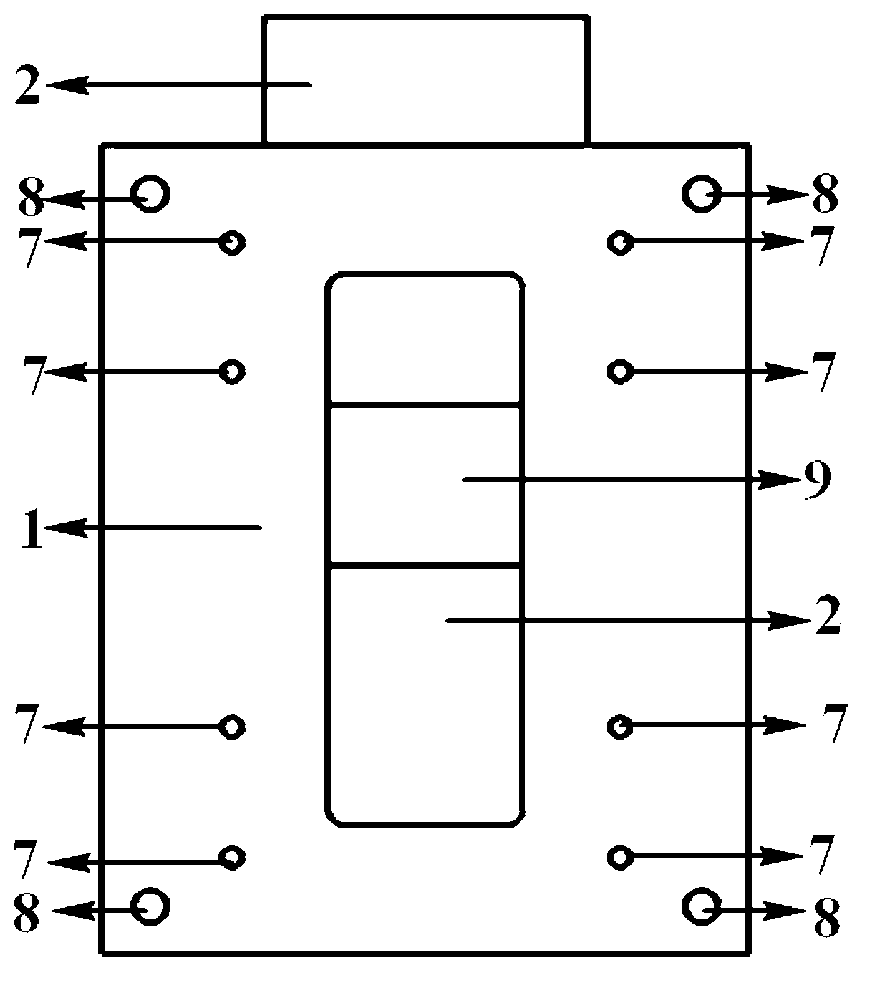

[0047] The compression fatigue test device for composite laminates with initial low-velocity impact damage provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0048] Such as figure 1 , 2 , 3 and 4, the present invention includes two guiding units 1, two loading units 2, two transfer units 3, two fixing units 4, eight slide rail units 5, eight bolt tightening units 6, ten Six bolt connection units 7 and four screw connection units 8 . Each guide unit 1 needs to be connected with four slide rail units 5 through the bolt connection unit 7, and the two guide units 1 hug the two loading units 2 through four screw connection units 8, and the two loading units 2 have T-shaped hole slots One side of the two loading units needs to face inward and correspond to each other, and ensure that the side with the bolt holes of the two loading units faces one direction, each loading unit 2 contains a transfer unit 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com