Static load, stability and impact testing machine for chairs, cabinets, tables, beds and screens

A testing machine and screen technology, applied in impact testing, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inaccurate loading force value and displacement control, single testing items, low automation level, etc., to achieve The effect of improving the level of integration, flexible operation and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

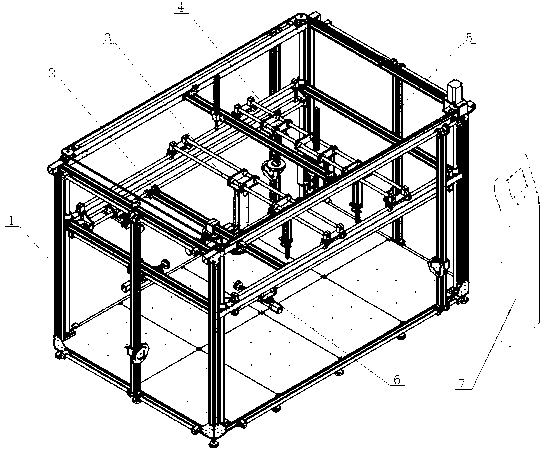

[0021] Such as figure 1 As shown, a chair, cabinet, table, bed, screen static load, stability, and impact testing machine includes a frame assembly 1, a first moving beam assembly 2, a second moving beam assembly 3, a third moving beam assembly 4, and a moving vertical beam Assembly 5, horizontal electric cylinder assembly 6 and control cabinet 7, wherein: the first moving beam assembly 2, the second moving beam assembly 3, the third moving beam assembly 4, the moving vertical beam assembly 5, and the horizontal electric cylinder assembly 6 are respectively connected with the machine The frame assembly 1 is connected, and the control cabinet is respectively connected with the frame assembly 1, the first moving beam assembly 2, the second moving beam assembly 3, the third moving beam assembly 4, the moving vertical beam assembly 5, and the horizontal electric cylinder assembly 6. Described mobile vertical beam assembly 5 has 4 pieces, and horizontal electric cylinder assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com