Full-vision semi-automatic coupling platform

A semi-automatic and visual technology, applied in the field of optoelectronics, can solve problems such as difficult operation, affecting coupling efficiency and yield, and achieve the effect of convenient operation, simple structure, and prevention of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

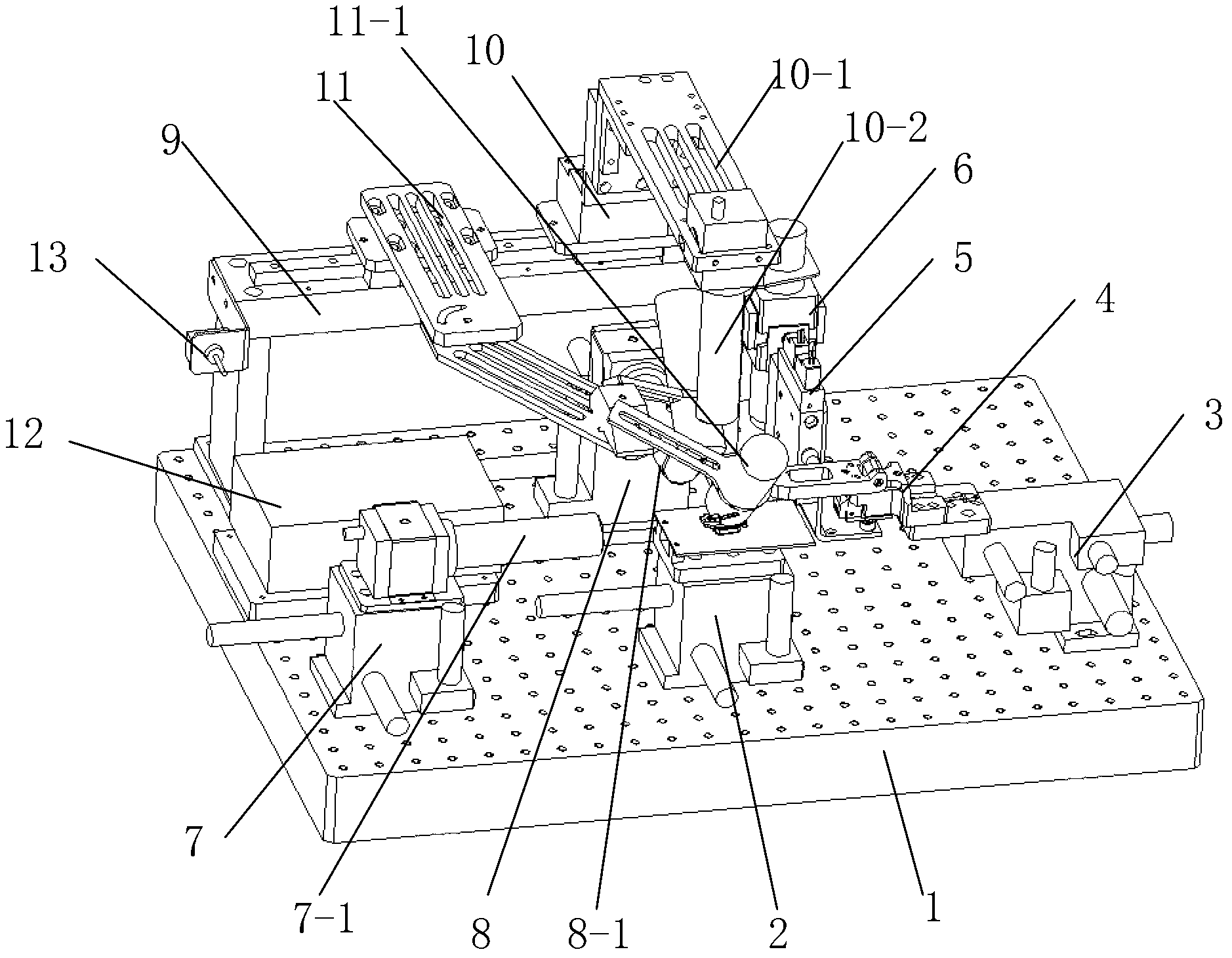

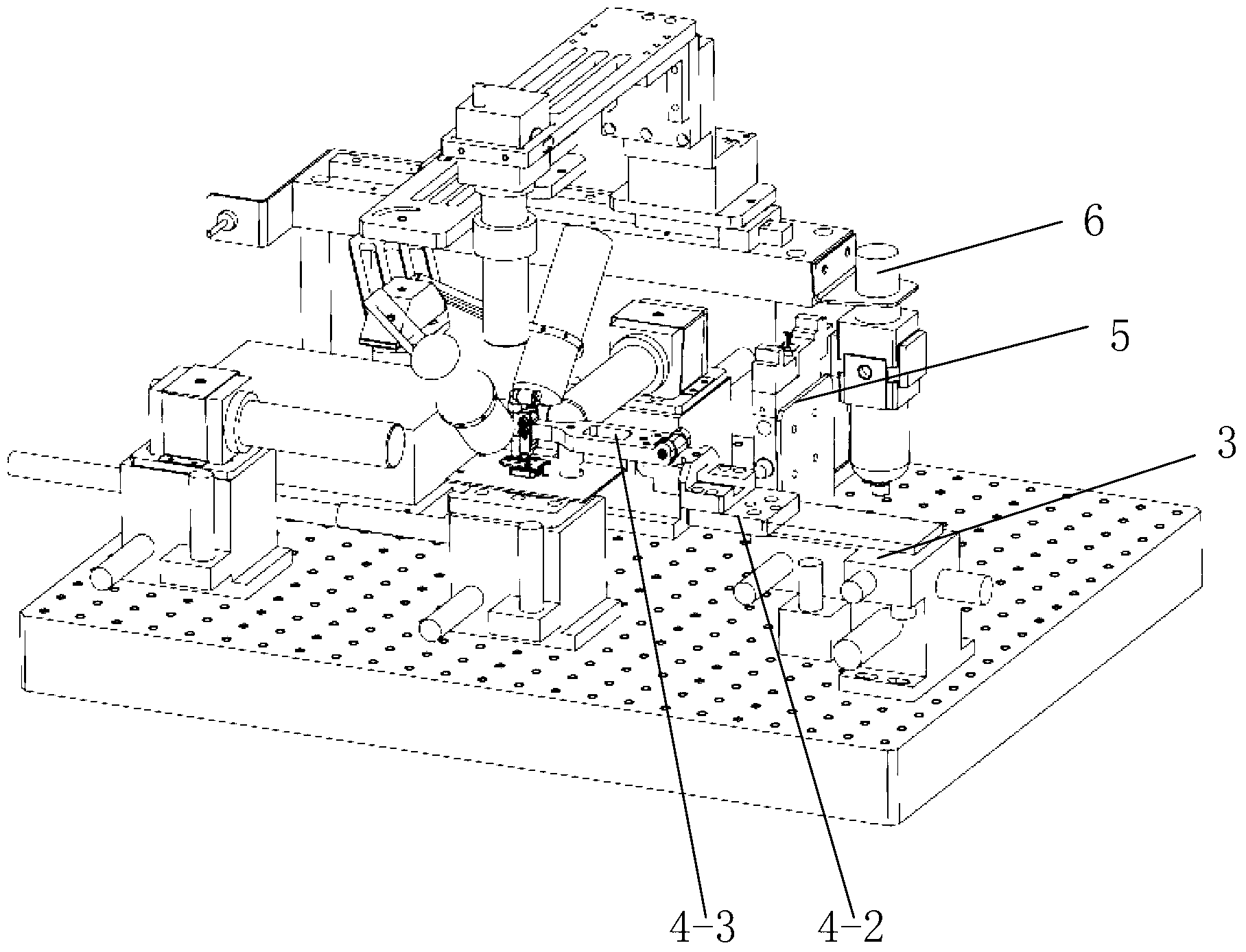

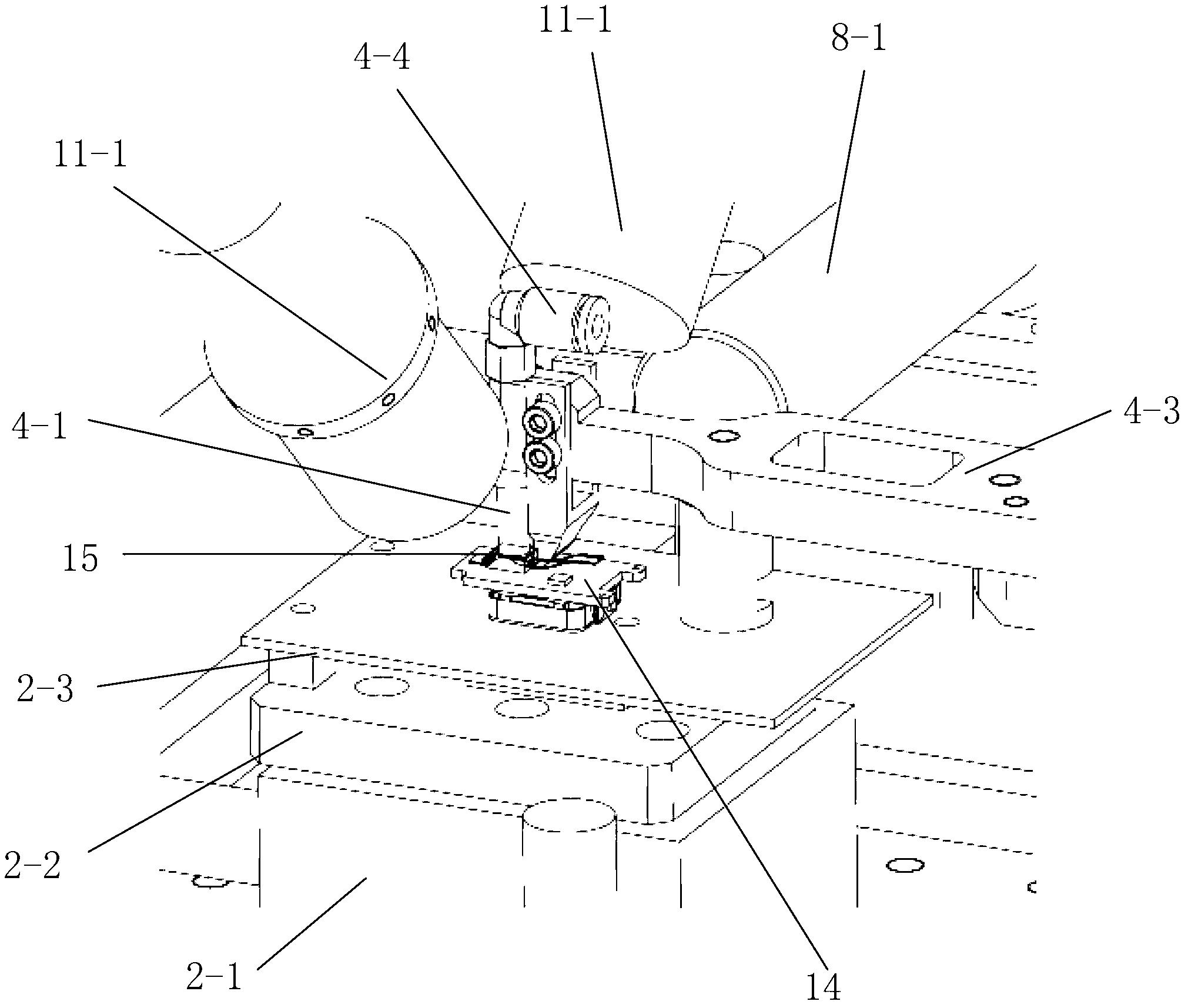

[0037] Such as figure 1 , 2As shown in and 3, a fully visual semi-automatic coupling platform includes an optical breadboard shockproof table 1, an object installation adjustment frame 2, a six-dimensional adjustment frame 3, a vacuum nozzle installation rotation mechanism 4, a compressed air filter valve 5, and a vacuum valve 6 , Side view camera installation adjustment frame 7, rear view camera installation adjustment frame 8, translation slide table 9, overlooking camera installation adjustment frame 10 and UV ultraviolet irradiation system installation frame 11;

[0038] The optical breadboard anti-vibration table 1 is a cuboid platform, and an object installation adjustment frame 2 is fixed on its upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com