Novel heating stove

A heating stove and a new type of technology, which can be applied to household stoves/stoves, stoves/stoves with hot water devices, and household heating, etc. pollution and other problems, to achieve the effect of adjusting the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

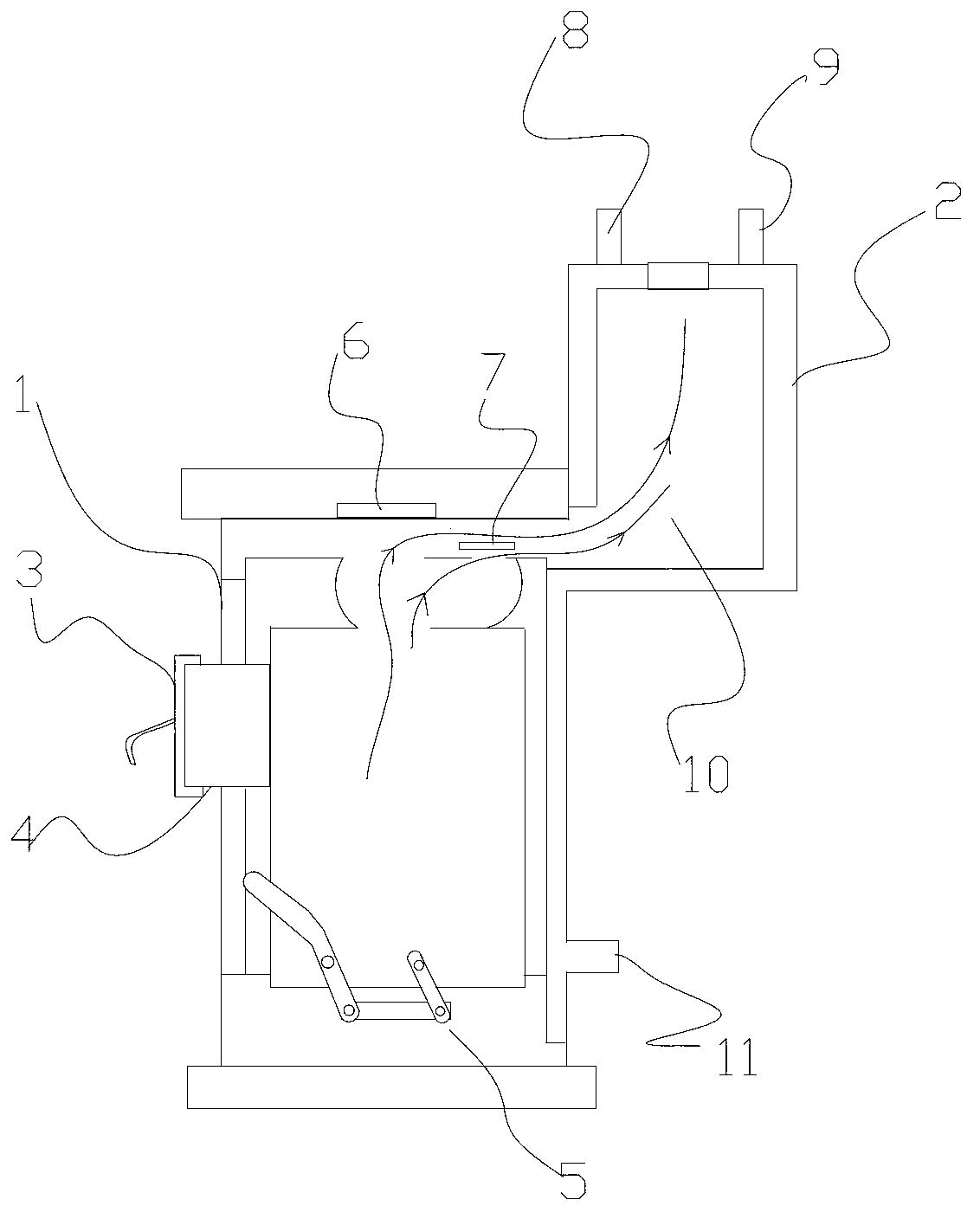

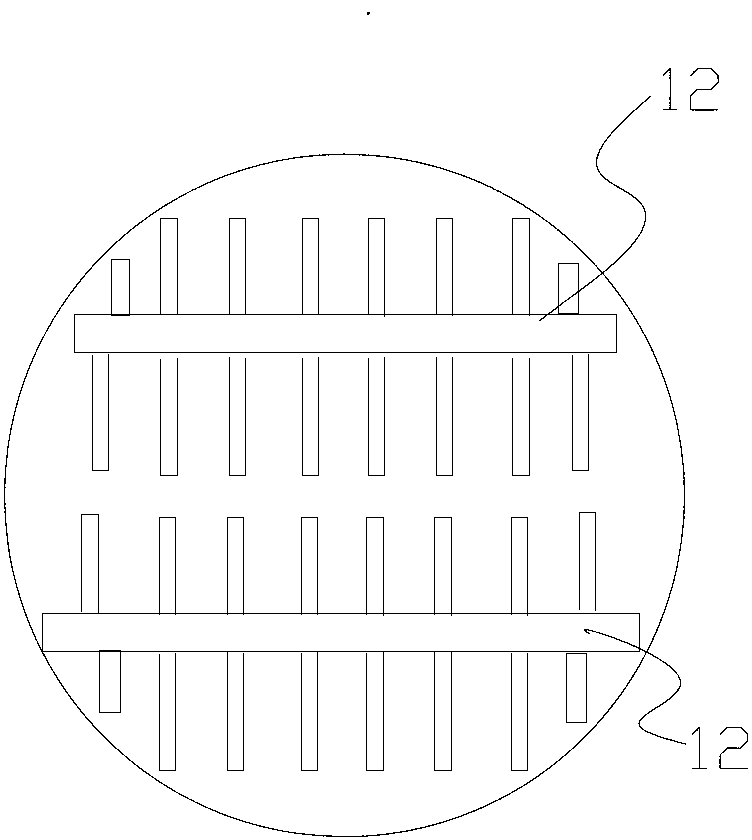

[0017] see Figure 1~3 As shown, a novel heating furnace includes a furnace body 1 and an interlayer water jacket 2 arranged on the furnace body. The inner bottom of the furnace body 1 is provided with a rotatable fire grate 12, and the inner furnace mouth of the furnace body 1 is provided with An adjustable fire extinguisher 6; the interlayer water jacket 2 is surrounded by a flue 10, and the interlayer water jacket 2 has a water inlet 11 and a circulating water outlet 9.

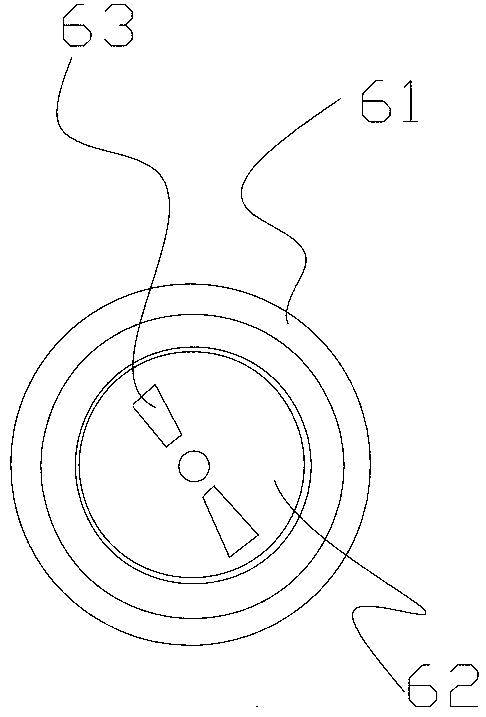

[0018] see image 3 As shown, the adjustable annealer 6 includes a support plate 61, the upper end of the support plate 61 is pivotally provided with a dial 62, and the surface of the support plate 61 and the dial 62 are provided with an annealing adjustment hole 63.

[0019] When in use, by turning the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com