Animal feeding trough

A technology for feeding troughs and livestock, applied in the field of breeding tools, can solve the problems of inconvenient cleaning of livestock feeding troughs, and achieve the effects of reducing the breeding of flies and bacteria, improving histocompatibility, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

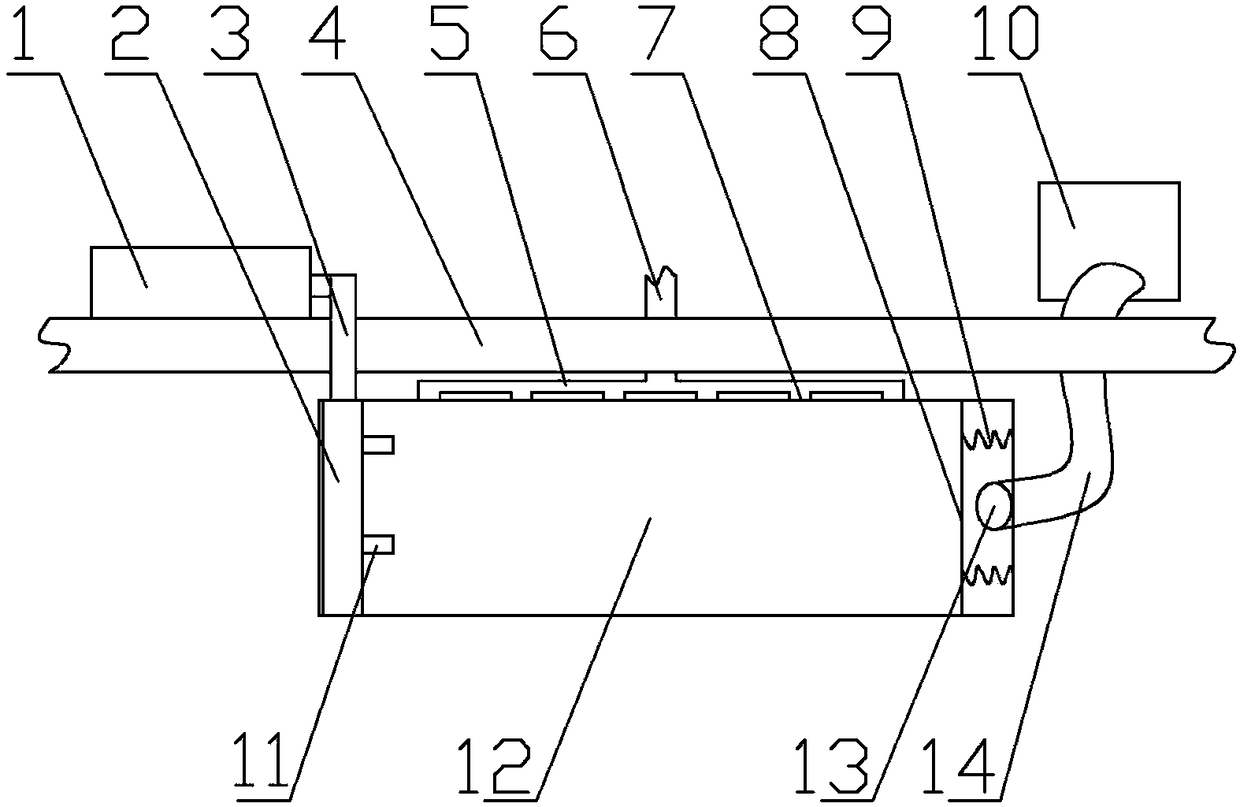

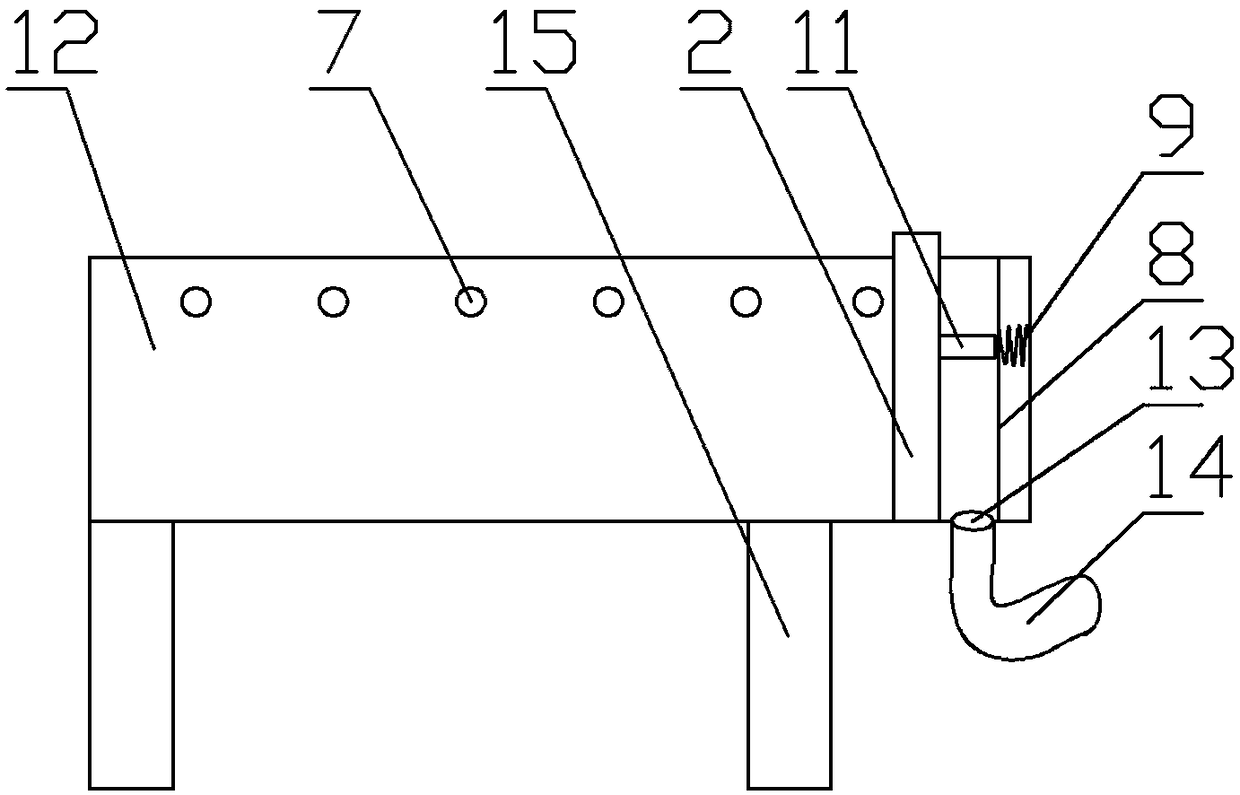

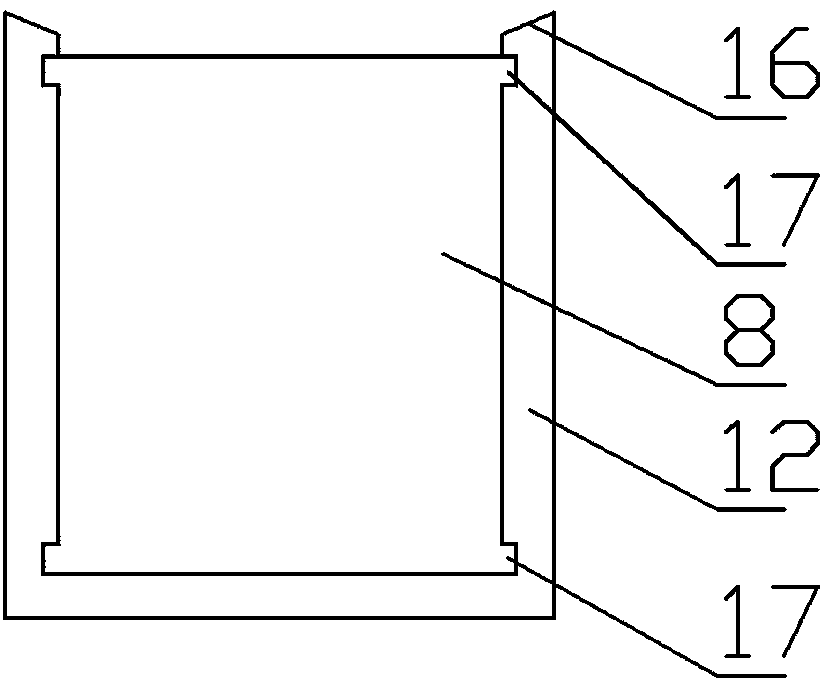

[0026] according to Figure 1-Figure 3 , a livestock trough, which includes a stainless steel tank 12 close to the fence 4 on one side; legs 15 are provided below the tank 12; a push plate 2 is provided at one end of the tank; the push plate 2 Fitted with the inner wall of the tank body 12; the push plate 2 is provided with a connecting rod 3 extending into the outside of the fence; the fence 4 is provided with a pushing device 1 connected with the connecting rod 3; A collection hole 13 is provided at the bottom of one end; a collection box 10 is provided on the outside of the fence; the collection hole 13 is connected to the collection box 10 through a connecting pipe 14; a vertically divided baffle plate 8 is provided in front of the collection hole 13 ; The baffle plate 8 is slidingly connected to the tank body 12; a spring 9 is provided between the end of the baffle plate and the tank body; the push plate 2 is provided with a push rod 11 corresponding to the baffle plate 8...

Embodiment 2

[0038] As another invention point of the present invention, the present invention also improves the push plate material, improves its mechanical properties and aging resistance, and has certain antibacterial properties; the push plate is prepared according to the following steps:

[0039] 1) Mix polypropylene resin, phenolic resin, ethylene-vinyl acetate copolymer, polycarbonate, triallyl cyanurate and oleic acid amide in a mass ratio of 50:10:5:3:2:1 Evenly, add to the internal mixer, the internal mixing time is 10min, the internal mixing temperature is 85°C, and component A is obtained;

[0040] 2) Mix nano-titanium dioxide and nano-silver evenly at a mass ratio of 2:1 to obtain a mixture, then add it to twice the weight of deionized water, stir well, and then add hexamethylcyclotrisiloxane with the same mass as nano-silver , heated to 80°C, under the condition of heat preservation, ultrasonic dispersion treatment for 10min, and then naturally cooled to room temperature to o...

Embodiment 3

[0044] Taking Example 2 as an example, various aspects of performance of the push plate material have been detected:

[0045] Among them, a control group is set up, in which,

[0046] Control group 1: without adding component B, the rest are the same as in Example 2;

[0047] Control group 2: No component C was added, and the rest were the same as in Example 2.

[0048] The tensile strength, elongation at break, and yellowing index were tested respectively, as shown in Table 1:

[0049] Table 1

[0050] group

[0051] Conclusion: By adding a certain proportion and type of auxiliary materials, the tensile strength, elongation at break and anti-aging ability can be significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com