Electronic expansion valve

A technology of electronic expansion valve and valve needle, which is applied in the direction of lifting valve, valve device, valve details, etc., can solve the problems of increasing the risk of system leakage, complex controller, and increasing system assembly cost, so as to reduce the risk of leakage, The effect of reducing the assembly process and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage.

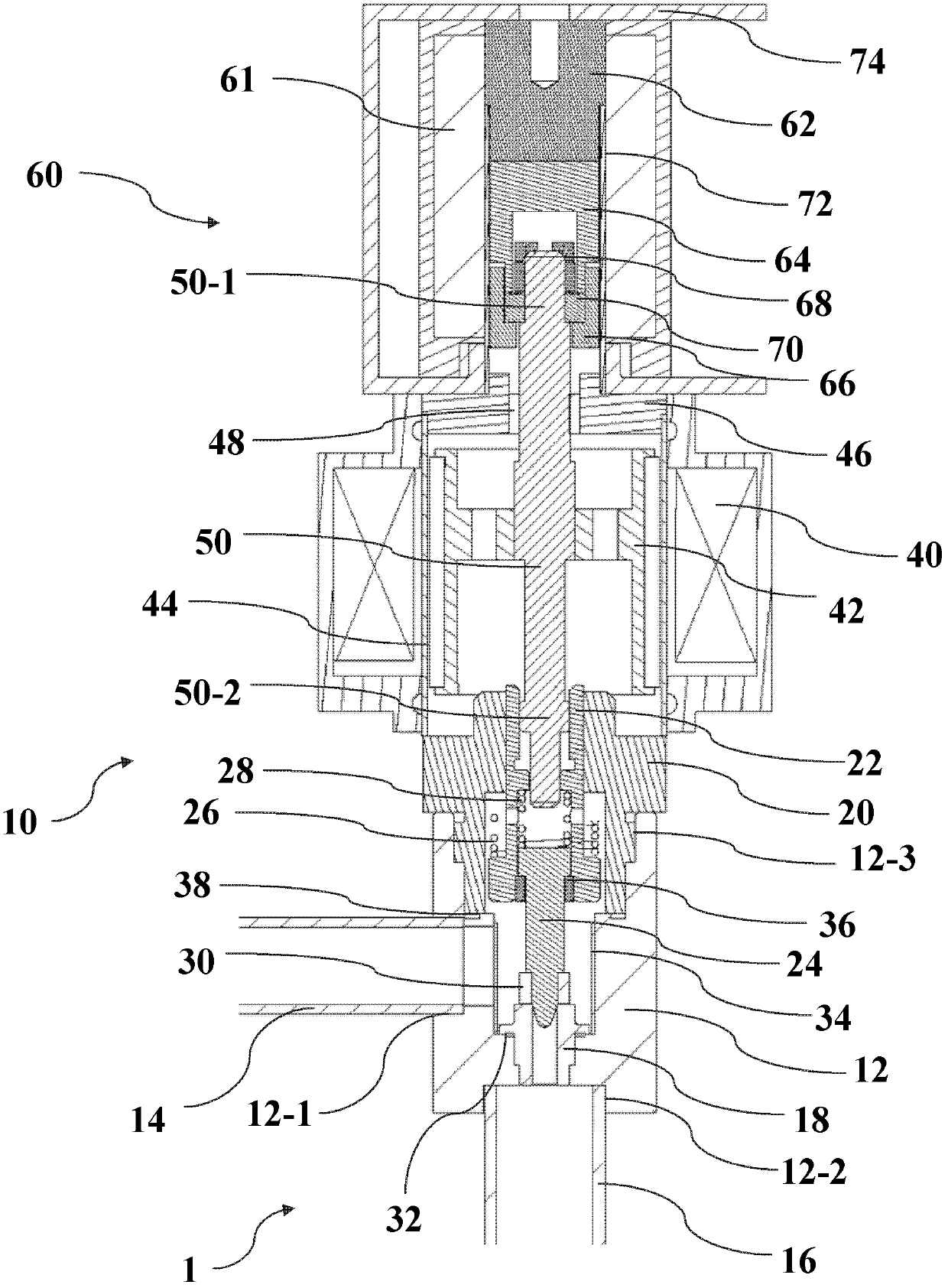

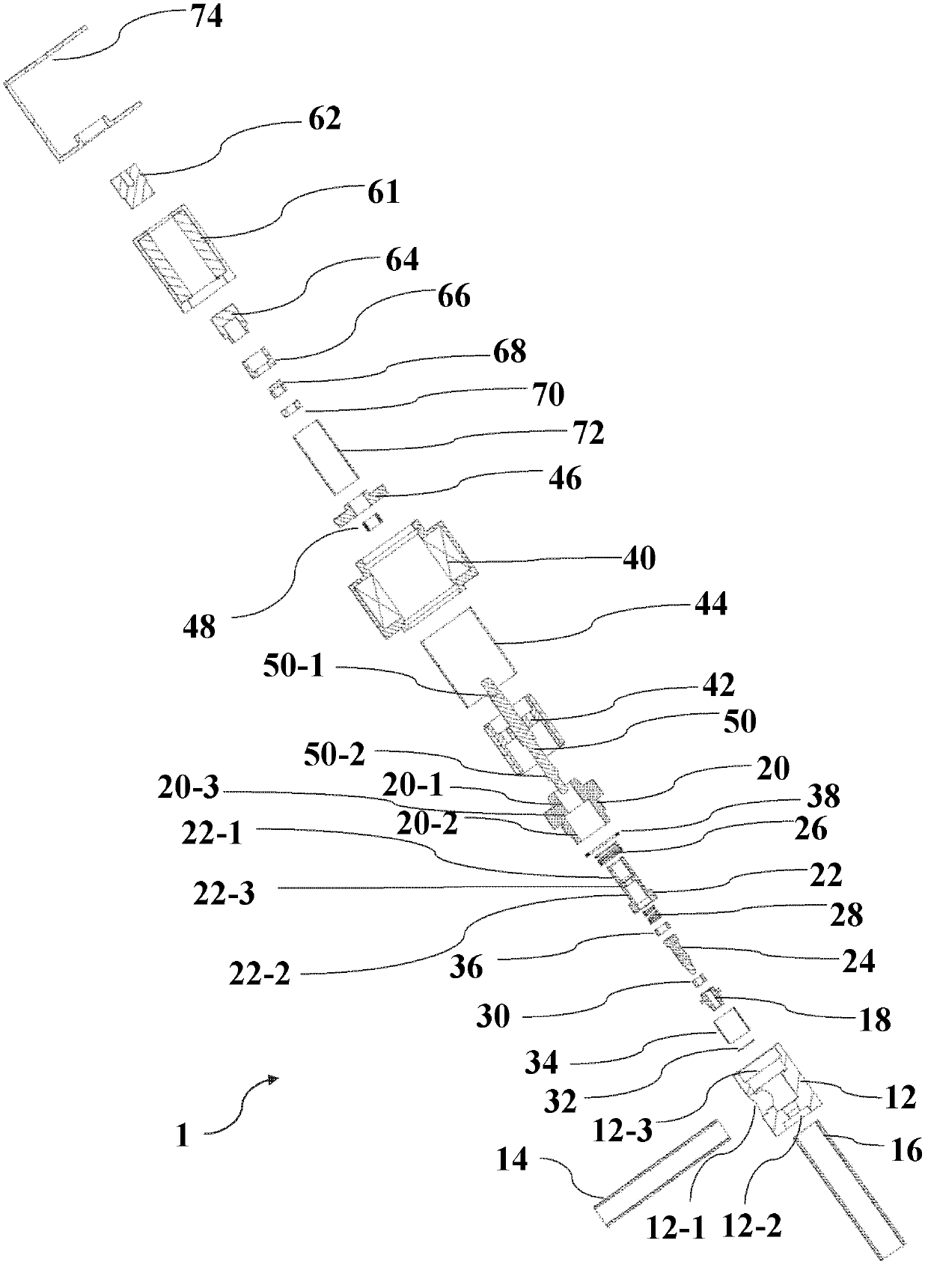

[0058] first refer to Figure 1-4 The configuration of the electronic expansion valve according to the first embodiment of the present invention is described.

[0059] The electronic expansion valve 1 according to the present invention may include a valve part 10 for regulating the flow rate of fluid flowing through the electronic expansion valve and an electromagnetic holding mechanism 60 for holding and releasing the actuator in the valve part 10 .

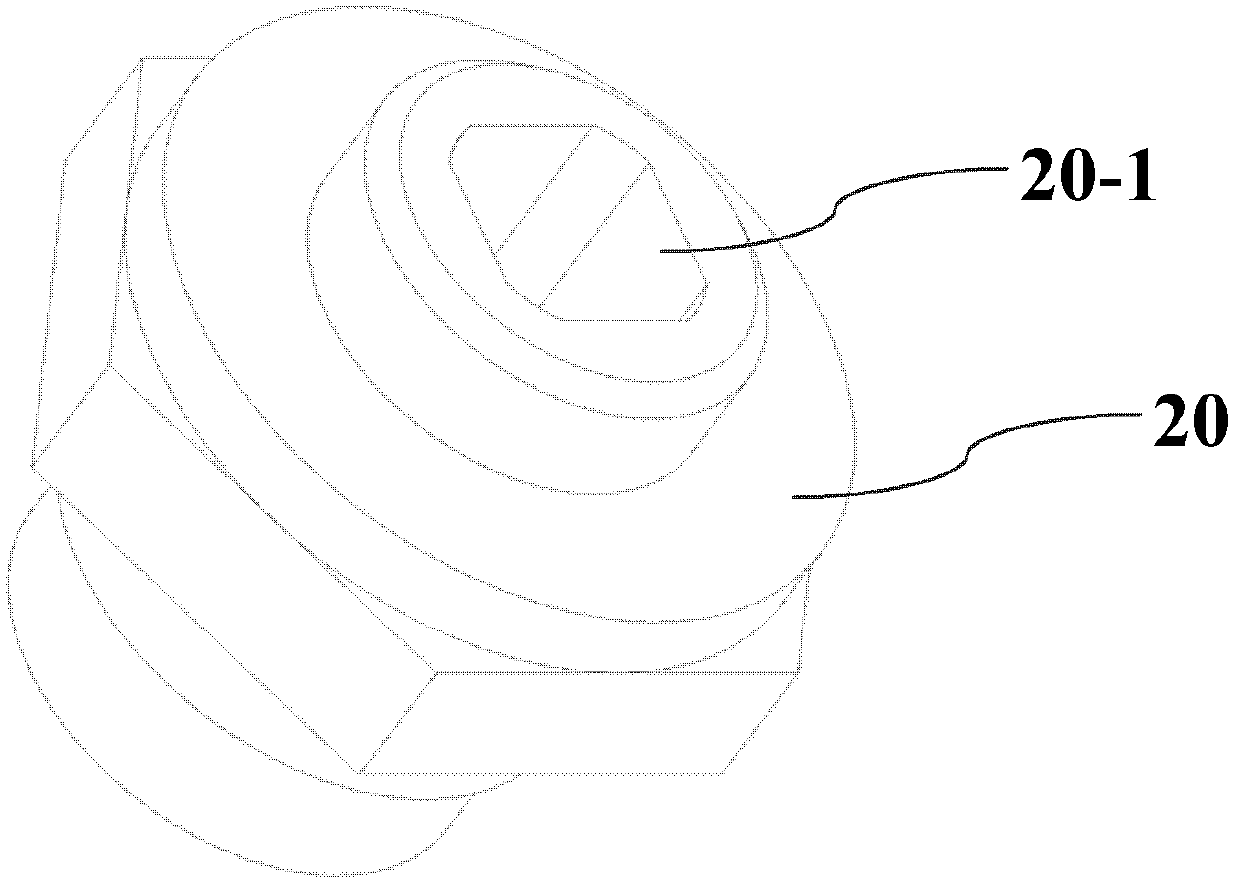

[0060] Specifically, the valve component 10 may include a valve body 12 . The valve body 12 is provided with an inlet 12 - 1 connected to the inlet pipe 14 and an outlet 12 - 2 connected to the outlet pipe 16 . A valve seat 18 may be provided at the outlet 12 - 2 of the valve body 12 . The electronic expansion valve 1 may further include a valve needle 24 capable of opening and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com