Biaxial harmonic gear pump

A gear pump and harmonic technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., to achieve the effects of reduced leakage, stable operation, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

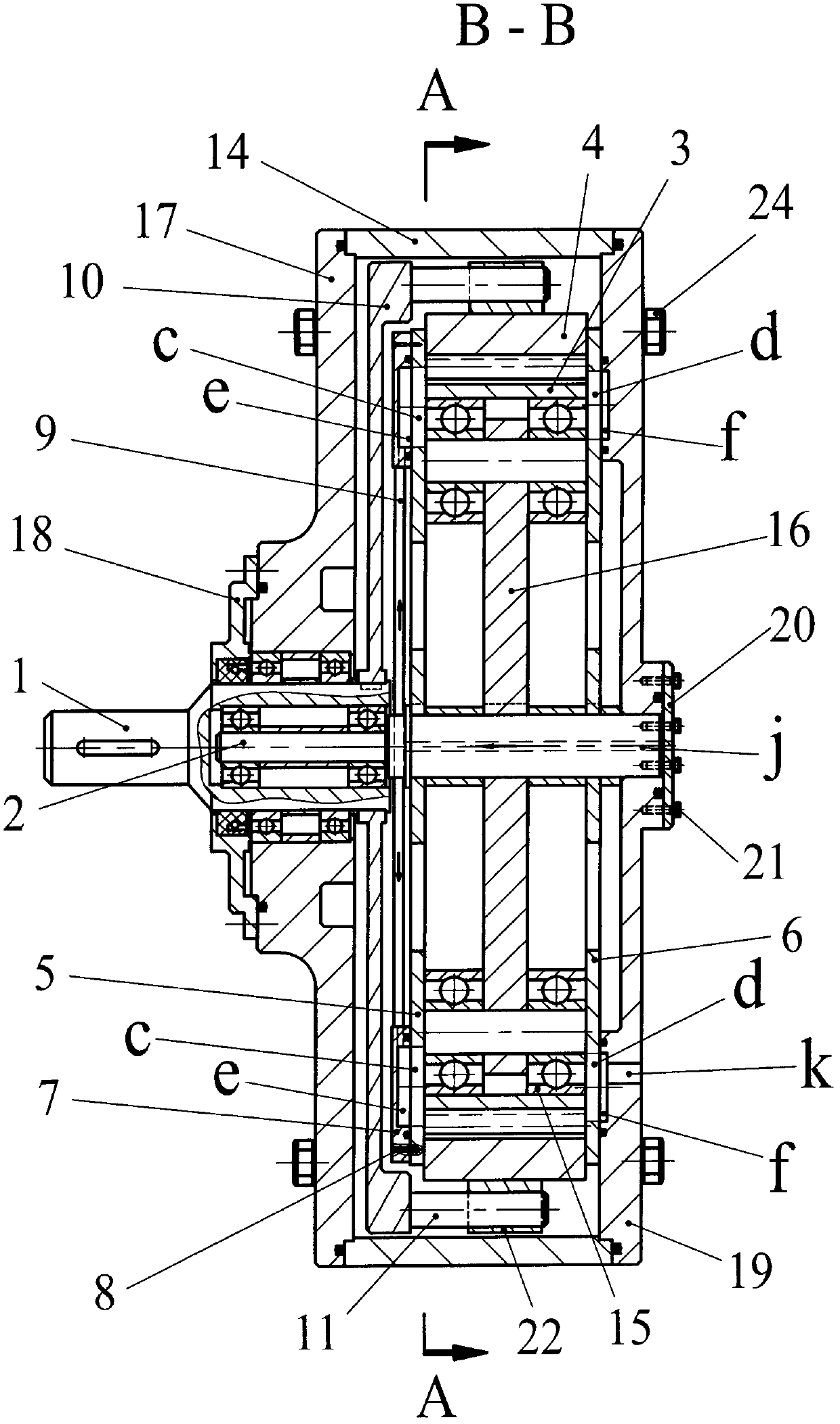

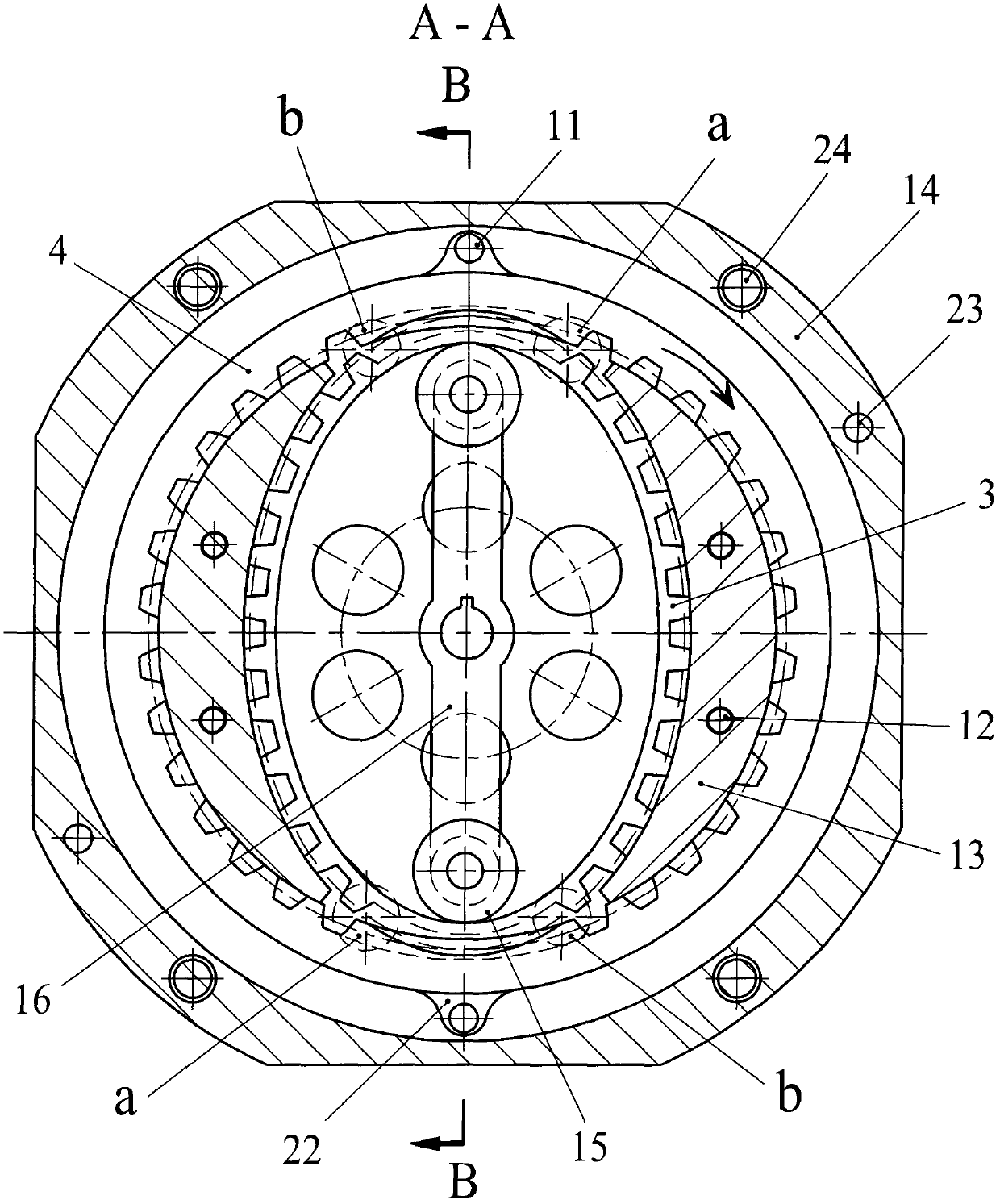

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] figure 1 and figure 2 It is an embodiment disclosed by the present invention. The double-shaft harmonic gear pump of the present invention consists of a transmission shaft 1, a mandrel 2, a flexible spline 3, a rigid spline 4, a left side plate 5, a right side plate 6, a sealing block 13, a rigid spline rotating arm 10, a column pin 11, Bearing seat 17, roller 15, support arm 16, shaft end cover 20, pump body 14, pump cover 19 etc. are made up. The transmission shaft 1 is set on the left end of the mandrel 2 and can rotate around the mandrel 2; the flexible spline 3 is a thin-walled external gear that can produce elastic deformation, and is installed on the outer ring of the roller 15; the rigid spline 4 is a rigid internal gear. An ear seat 22 is arranged on it; the flexible spline 3 meshes with the rigid spline 4, both ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com