Method for diagnosing electrical contact connection of an exhaust gas sensor

A technology of exhaust sensor and electrical contact, which is applied in the direction of electric control of exhaust treatment devices, exhaust treatment, testing of electrical devices in transportation, etc., to achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

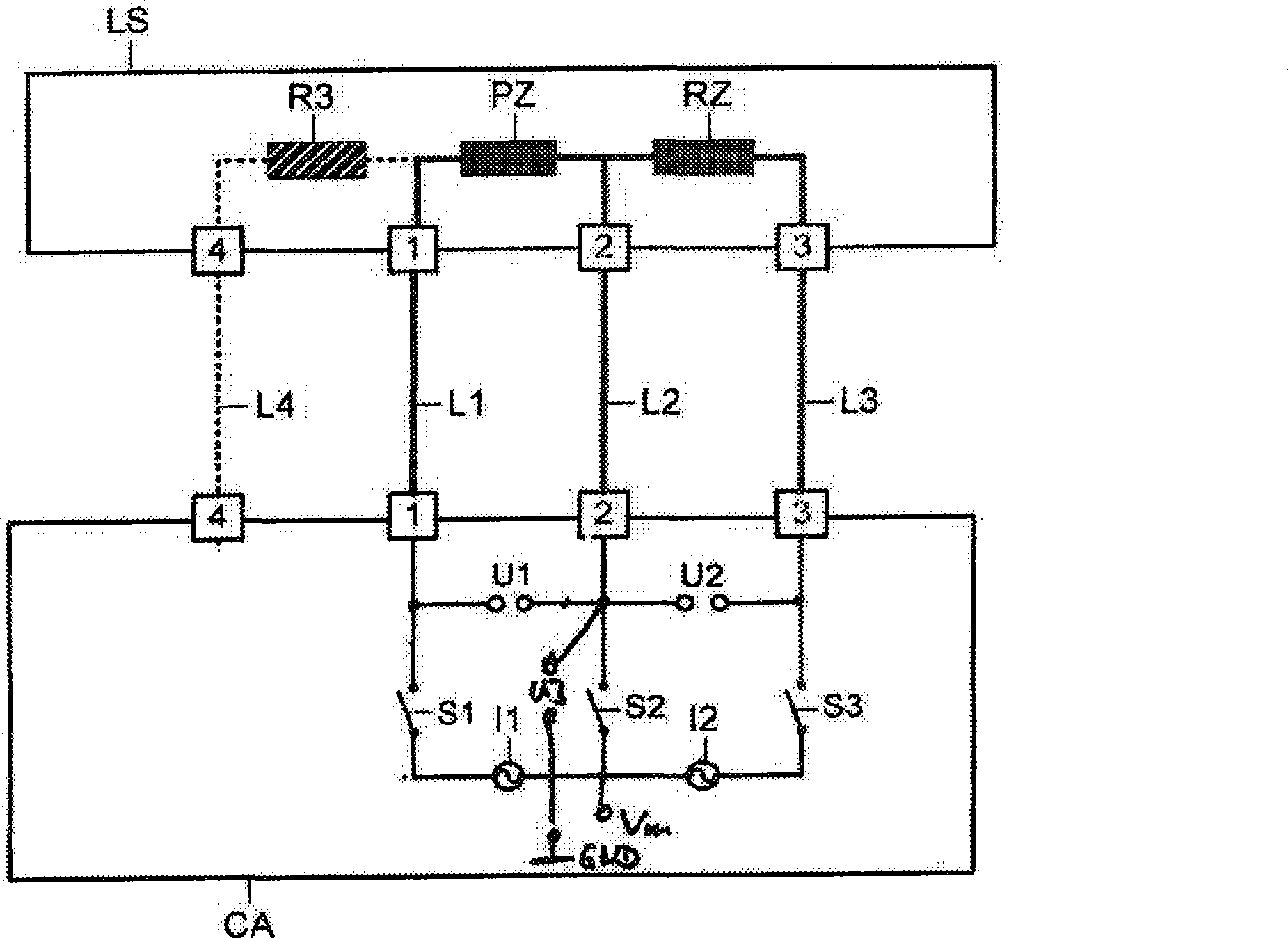

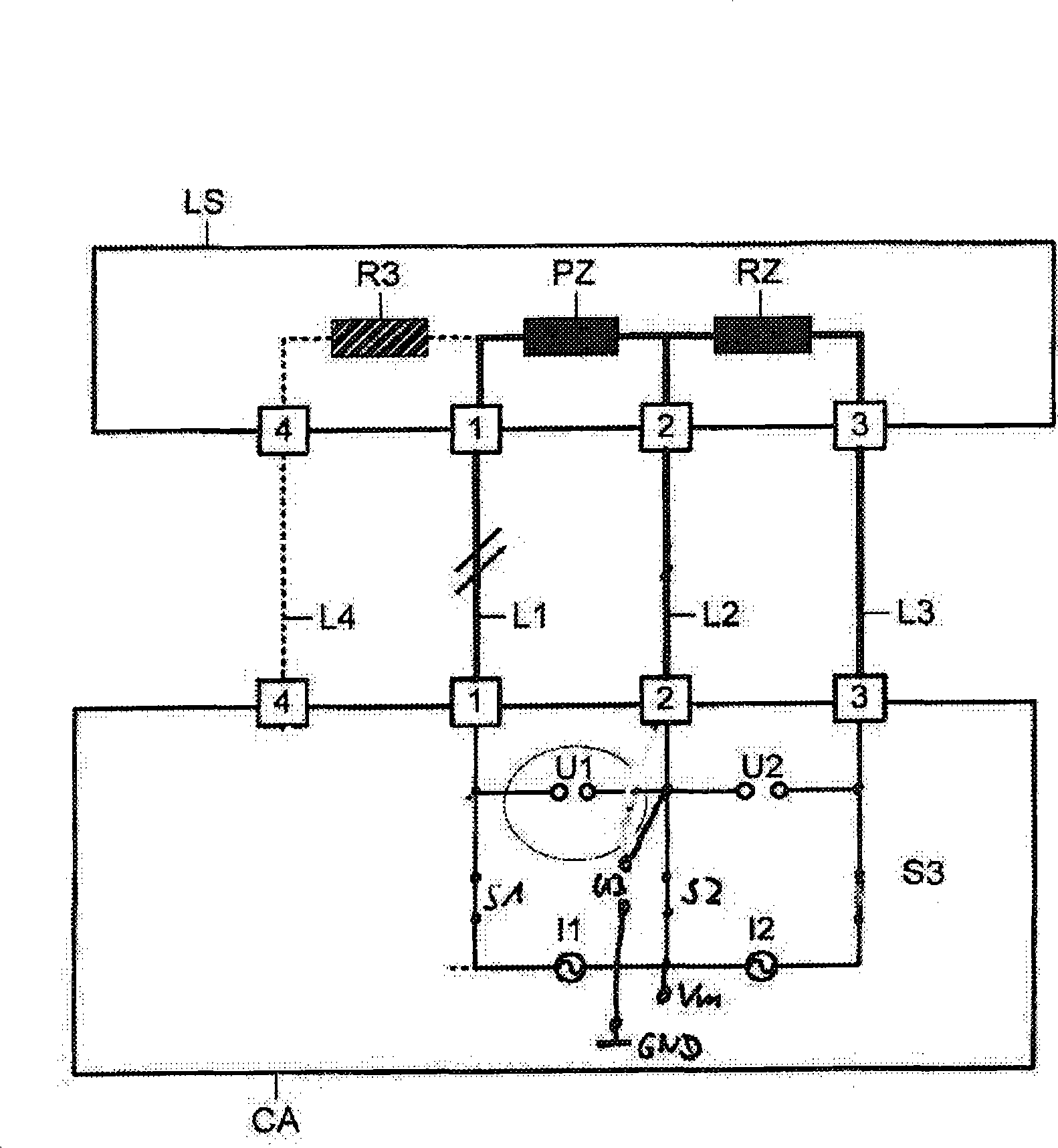

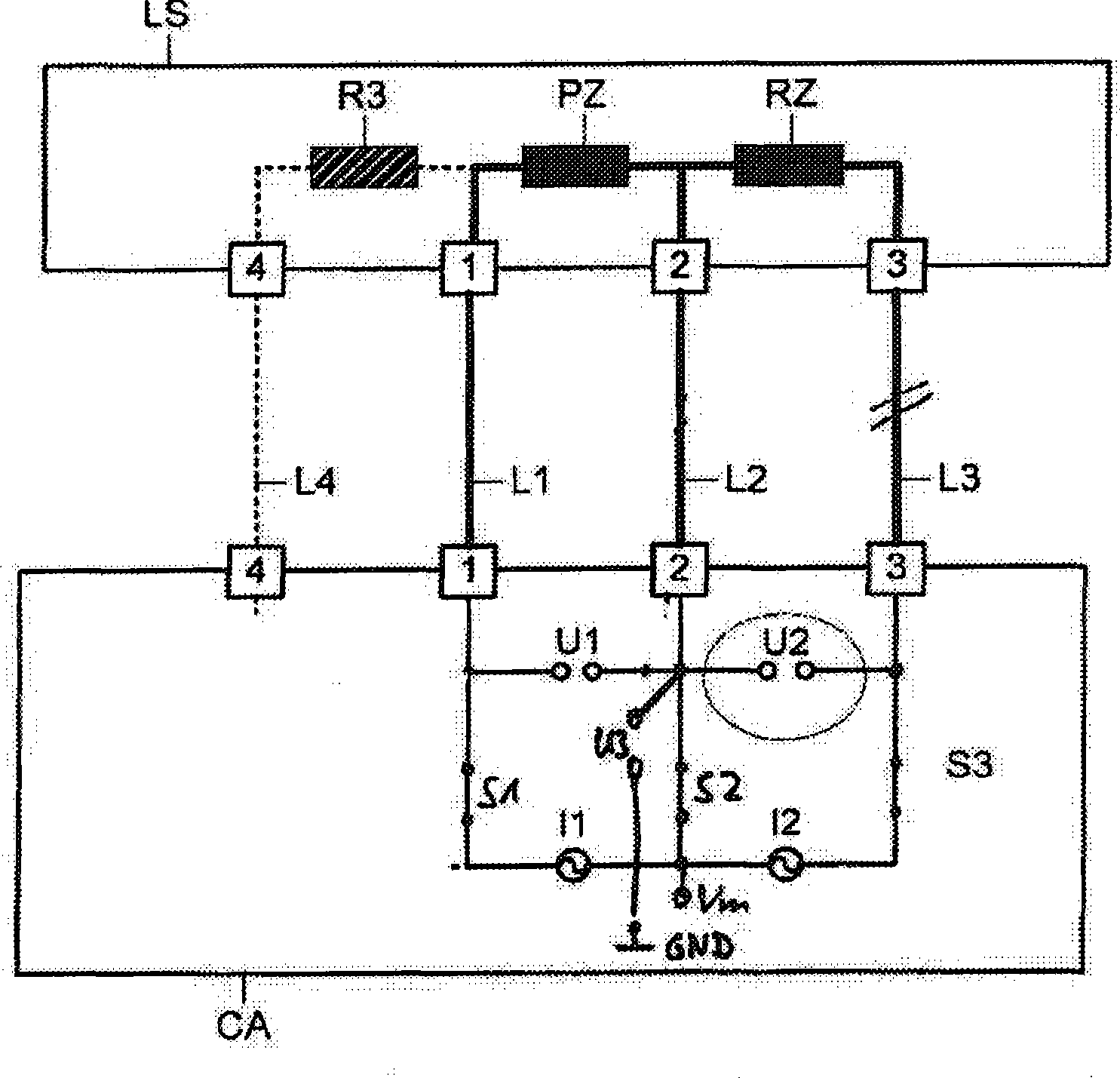

[0018] figure 1 A schematic diagram of a device CA for carrying out the diagnostics according to the invention for the electrical contacting of an exhaust gas sensor LS in the form of a linear exhaust gas probe is shown.

[0019] The exhaust gas sensor LS includes a pump unit PZ as a first unit and a reference unit RZ as a second unit. The pump unit PZ is interconnected between the first terminal 1 and the second terminal 2 of the exhaust gas sensor. A reference unit RZ is interconnected between the second terminal 2 and the third terminal 3 of the exhaust gas sensor LS. These devices are the minimum configuration for an oxygen sensor. exist figure 1 In , an optional balancing resistor R3 is shown in dotted line, which is arranged between the first terminal 1 and the fourth terminal 4 . The balancing resistor R3 is used to compensate for manufacturing tolerances of the probe, ie the resistance value of the pump unit PZ.

[0020] The device CA including all means for diagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com