Cross-district double-U-shaped ventilating system for high-gas working face and application method for cross-district double-U-shaped ventilating system

A ventilation system and working face technology, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc. It can solve problems such as high maintenance costs, roadways that cannot be used for the next working face, and reduced coal recovery rate in the mining area. , to achieve the effect of increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

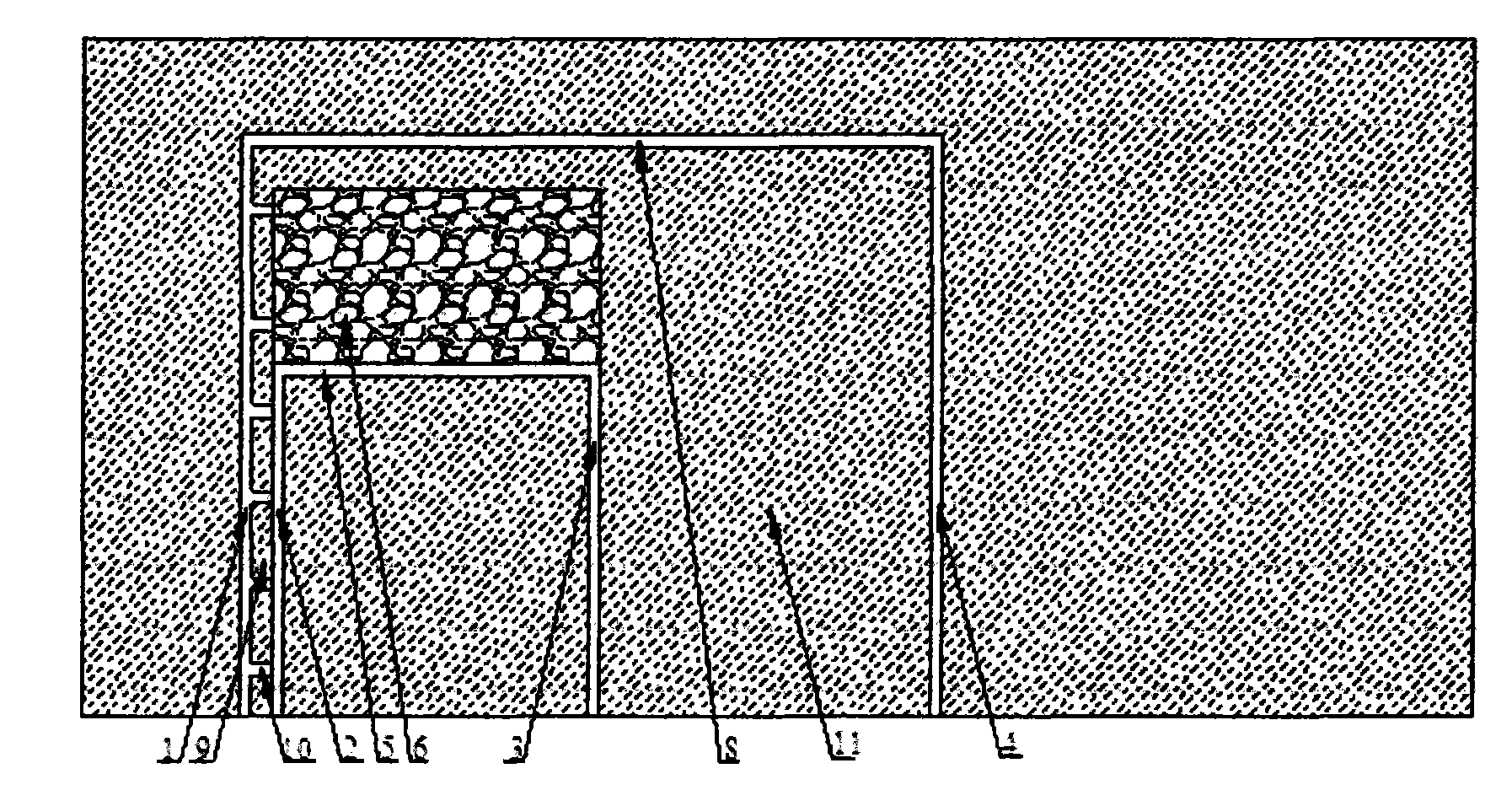

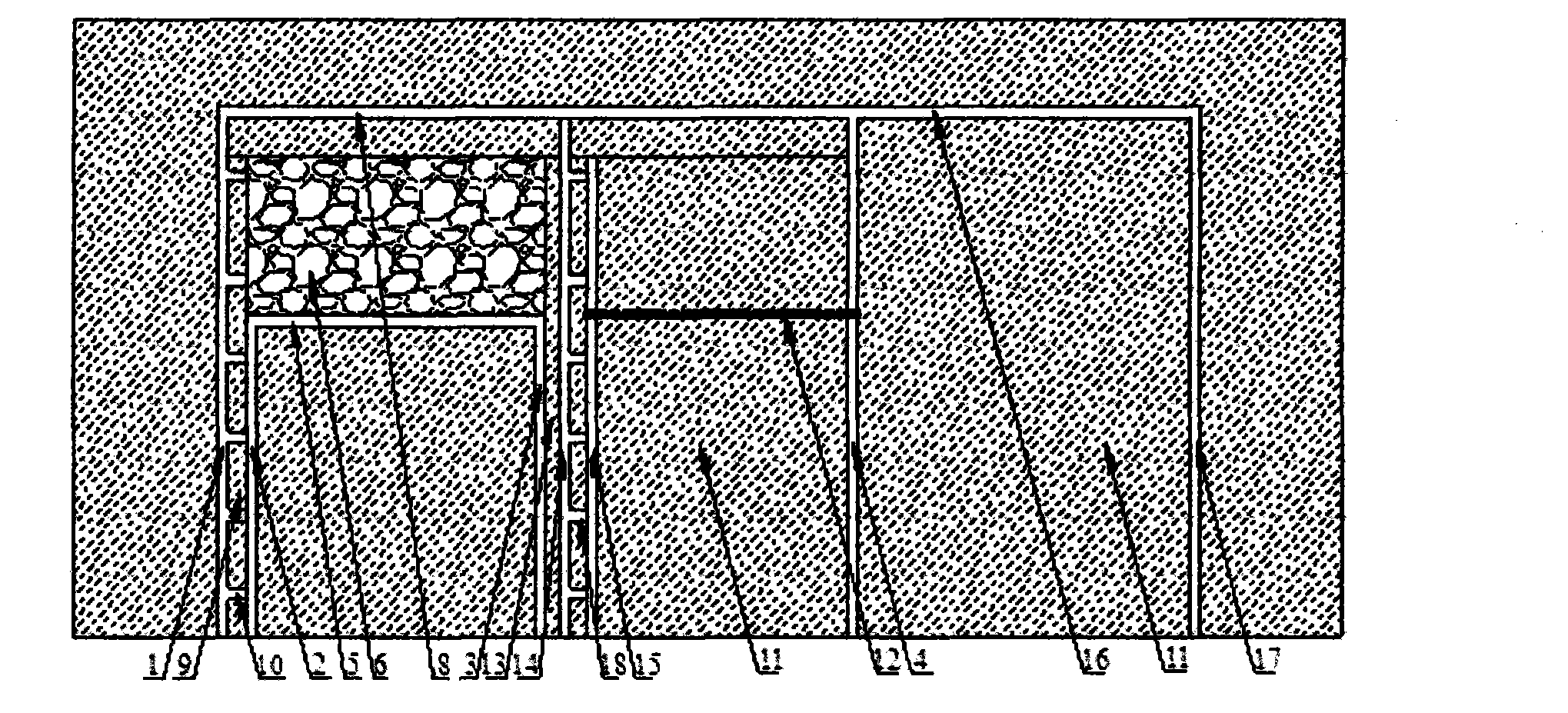

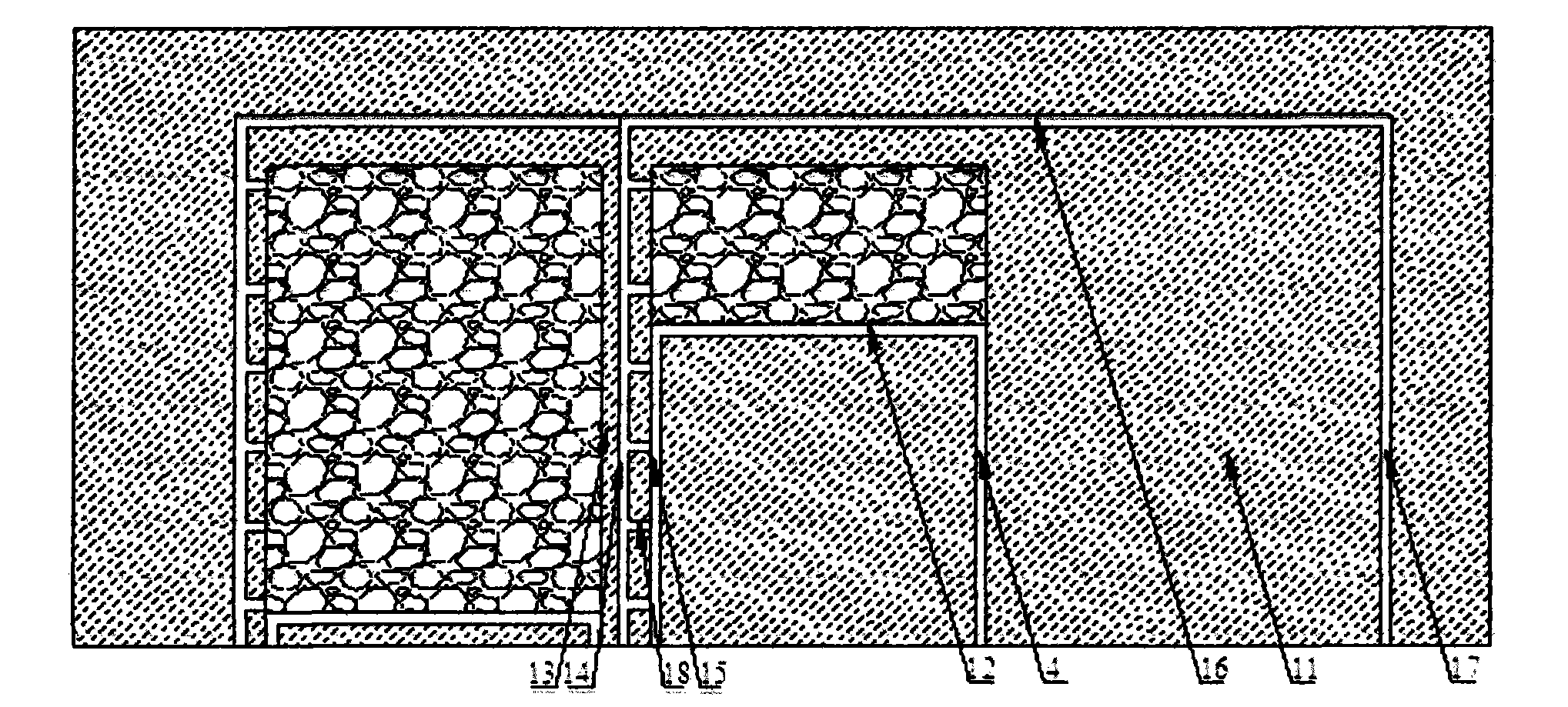

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the cross-section double U-shaped ventilation system of the high-gas working face in this embodiment includes: the working face 5, the goaf 6 located above the working face, and the return gas tailgates arranged in sequence from left to right 1. Return air alley 2, air inlet alley 3 and air inlet tile exhaust alley 4 (four ventilation alleys with two inlets and two circuits). Both the air inlet lane 3 and the air return lane 2 are in communication with the working face 5 , thus constituting the inner U-shaped ventilation system of the working face 5 . The return air tile exhaust alley 1 and the air inlet tile exhaust alley 4 are arranged on both sides of the working face 5, and the two are connected through the auxiliary cutout 8, thereby constituting the outer U-shaped ventilation system of the working face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com