Autoclaved aerated concrete double-hard-face building block and manufacturing and construction method thereof

A technology of autoclaved aeration and concrete, which is applied in the direction of manufacturing tools, building materials, ceramic molding machines, etc., can solve the problems of easy collapse failure, low density, insufficient durability, etc., to achieve enhanced masonry strength, low transformation investment, The effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

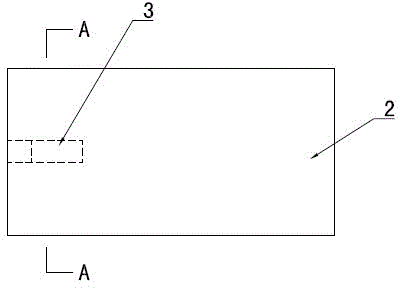

[0043] Embodiment 1, with reference to attached figure 1 , 2 : Autoclaved aerated concrete double-hard surface block is used for the inner wall of a house with a large depth, and belongs to the wall that bears the pressure load and impact load of the vertical wall. The size of the autoclaved aerated concrete double-hard surface block is length×width×height=600×240×300 mm, and the thickness of the hard surface area 2 is 30 mm. The block base area 1 has a thickness of 180 mm, the block base area 1 is autoclaved aerated concrete with a density of 300KG / M3, and the hard surface area 2 is 800KG / M 3 In the autoclaved aerated concrete, there is a tie bar 3 at the critical point between the block base area 1 and the hard surface area 2, and the tie bar 3 is a flat open iron piece. Before the cutting process is completed and the autoclaved curing is completed, the tie bar 3 The end face of the semi-finished block is inserted between the block base area 1 and the hard surface area 2 a...

Embodiment 2

[0059] The size of the autoclaved aerated concrete double hard surface block is length × width × height = 600 × 300 × 300 mm, the thickness of the hard surface area 2 is 50 mm, and the block base area 1 is autoclaved with a density of 350KG / M3 Air-entrained concrete, the hard surface zone 2 has a density of 800KG / M 3 autoclaved aerated concrete.

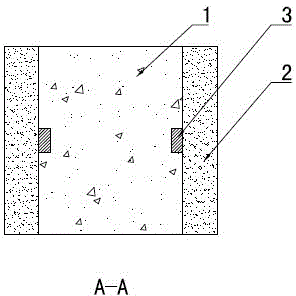

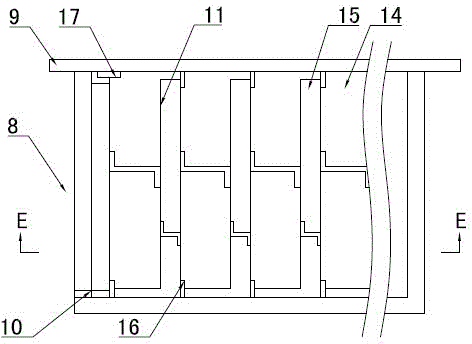

[0060] Design the partition assembly 11 that separates the mold into two casting areas, refer to the attached image 3 , 4 , Utilize horizontal positioning bar 10, vertical positioning bar 16 to arrange partition assembly 11 in the mould, and partition assembly 11 divides mold into block base layer cultivation area 14 and hard surface cultivation area 15; The width of base layer cultivation area 14 is 200 millimeters, The width of the hard surface layer breeding area 15 is 100 mm, and the embryo body cutting and separation line is located at the centerline of the width of the hard surface layer growing area 15;

[0061] All the ot...

Embodiment 3

[0063] Refer to attached Figure 7 : The construction of butt-joint end faces of autoclaved aerated concrete double-hard-faced blocks to strengthen the connection.

[0064] Autoclaved aerated concrete double-hard surface blocks are used for the top floor of the indoor counter. In addition to the bonding of the masonry joints, the rigidity between the blocks needs to be strengthened. The overall size of the lightweight cement-based hard surface layer block is length × width × height = 600 × 300 × 300 mm, and a connecting plug-in 4 is inserted into the opening of the tie bar 3. Through the connecting plug-in 4, the adjacent two Blocks are plugged together, and high-strength cement paste is applied before plugging, so that the shear resistance of the end face joints of the blocks can fully meet the requirements of the specification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com