Large-scale electrostatic spinning machine

An electrospinning machine and large-scale technology, applied in the field of electrospinning and nanomaterial systems, can solve problems affecting quality, high cost, and difficulty in large-scale preparation, and achieve high porosity, simple structure, and superior mass production performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

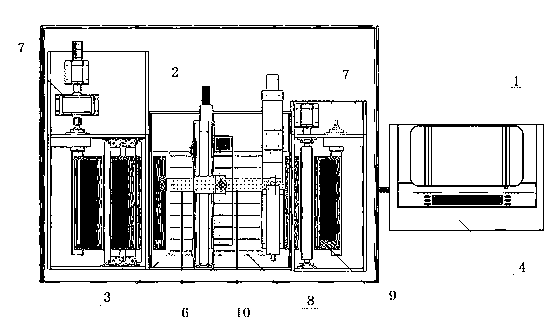

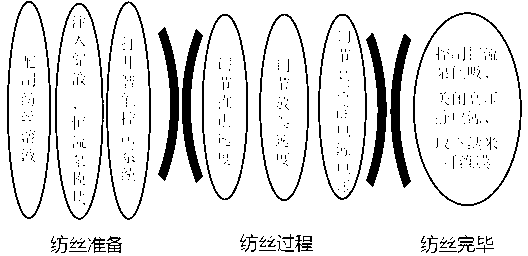

[0025] Such as figure 1 , 2 As shown, the large-scale electrospinning machine includes a high-voltage electrostatic source 1, an array needle spinning system 2, a collection system 3 and an intelligent control system 4; the array needle spinning system 2 includes a constant-current pump module 5, and a constant-current pump module 5 connected to the silk-forming module 6, the positive pole of the high-voltage electrostatic power source 1 is connected to the silk-forming module 6; the collection system 3 includes a transmission mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com