Method for preparing alkylation gasoline through polycondensation of methanol

An alkylated gasoline and alkylation technology, applied in the chemical industry, can solve problems such as energy consumption, and achieve the effects of reducing production energy consumption, reducing costs, and improving safety and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

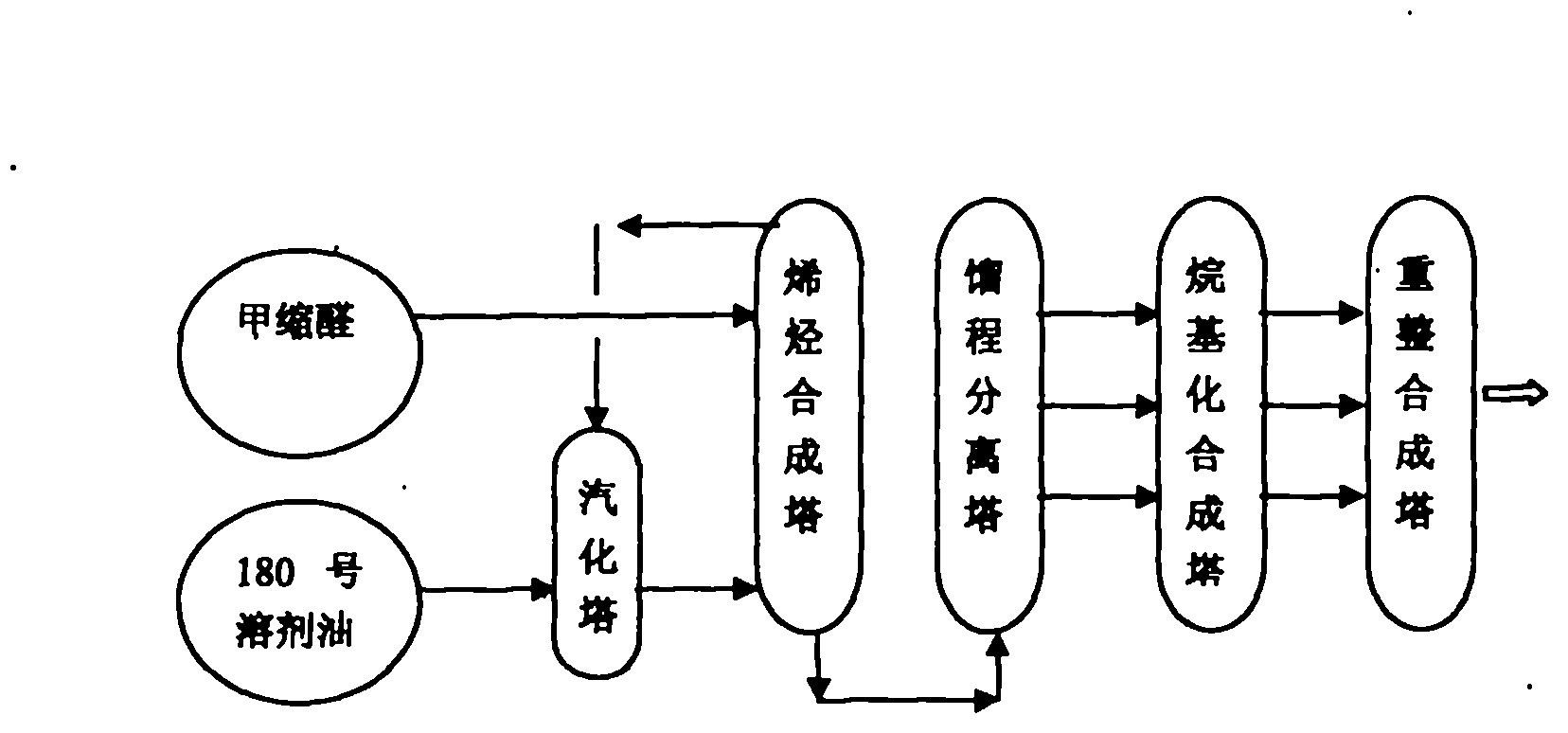

Method used

Image

Examples

Embodiment 1

[0068] The making of embodiment 1 methylal hydrocarbon structure catalyst:

[0069] 1) Raw materials: commercially available 4A\5A molecular sieves are used as the carrier, sulfuric acid and Rx+methanesulfonic acid are used as catalysts to produce Al / Si+ / Ca / Na / K / hydrogen type molecular sieves;

[0070] 2) Chemical etching of type A molecular sieve:

[0071] H 2 SO 4 Prepare a solution with a pH value of -1~+2, soak 4A\5A molecular sieves in acid solution for 3h~72h, air dry at 120°C, crystallize in hot air at 180°C~300°C for 5h~72h, and then Metal ions such as Ca / Na / K / are etched under conditions to obtain olefinized channels, and after washing and drying, crystallize at 300°C to 580°C to obtain hydrogen molecular sieve A.

[0072] 3) Production of B-type molecular sieve:

[0073] Prepare Rx + methanesulfonic acid into a solution of PH=-1~2, soak 4A\5A molecular sieves in the acid solution to etch metal ions Ca / Na / K3h~72h, after soaking, washing, neutralization, take out a...

Embodiment 2

[0075] Embodiment 2 Mixed hydrocarbon alkylation catalyst production:

[0076] 1) Raw material: ZSM-5 catalyst raw powder; tungstophosphoric acid; rare earth oxide: ReO 3 , La 2 o 3 , metal oxides: ZnO, Fe 2 o 3 , SnO 2 ; Commercially available 13X molecular sieves.

[0077] 2) Catalyst production:

[0078] A: Rare earth molecular sieve production: Dissolve rare earth oxides in dilute nitric acid to etch metal ions, adjust its pH value to between 0.1 and 4, mix with ZSM-5 catalyst 10% to 70%, and filter, dry, The pH value is adjusted, followed by crystallization at a temperature of 300°C to 600°C to obtain ZSM-5+rare earth alkylated molecular sieves.

[0079] B: Metal catalyst production: react rare earth oxides or metal oxides with dilute nitric acid to obtain nitrate, adjust the pH value of nitrate to a solution of 0.1 to 5, soak 13X molecular sieve in tungstophosphorus (heteropoly) acid 5h~72h, take it out and air dry it, and dry it in hot air at 100℃~200℃ for 1h~72...

Embodiment 3

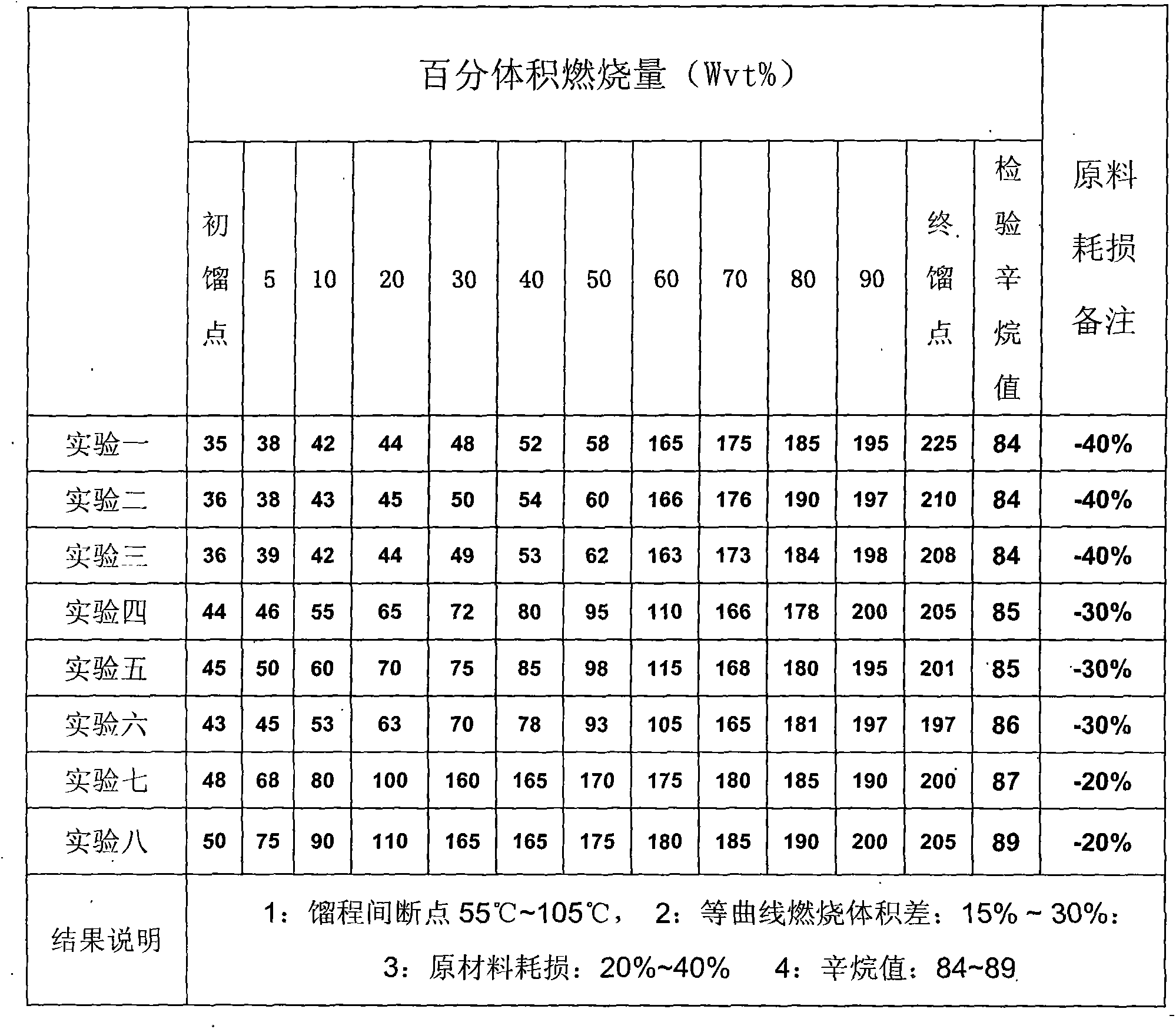

[0082] Laboratory Preparation of Alkylated Gasoline by Polycondensation of Methanol:

[0083] 1. Experimental conditions:

[0084] 1.1 Raw materials: methanol, methylal, commercially available No. 180 high boiling point solvent oil.

[0085] 1.2 Molecular sieve: 50g of olefin molecular sieve A\B according to the ratio of 1:1, and 20g of alkylated molecular sieve A / B according to the ratio of 4:2.

[0086] 1.3 Experimental equipment:

[0087] One 1000ml three-necked quartz flask, one 250ml separating funnel, one 600mm reflective reflux tower, one ¢50×200mm ground molecular sieve sleeve, one 500mm serpentine condenser tube, one 300W constant temperature heating jacket, one 1000ml volumetric flask , one 250ml reflux molecular sieve, one set of temperature controller at the top of the reactor.

[0088] 2. Experimental steps:

[0089] 2.1 Put the olefin catalyst A / B into the molecular sieve sleeve, and the alkylation catalyst A / B into the reflux molecular sieve, and use glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com