A kind of antibacterial and deodorant pvc sole foam material

A foaming material and foaming agent technology, applied in shoe soles, footwear, application and other directions, can solve the problems of poor moisture absorption and air permeability, easy to cause foot odor and athlete's foot, etc., and achieve a good effect of killing fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

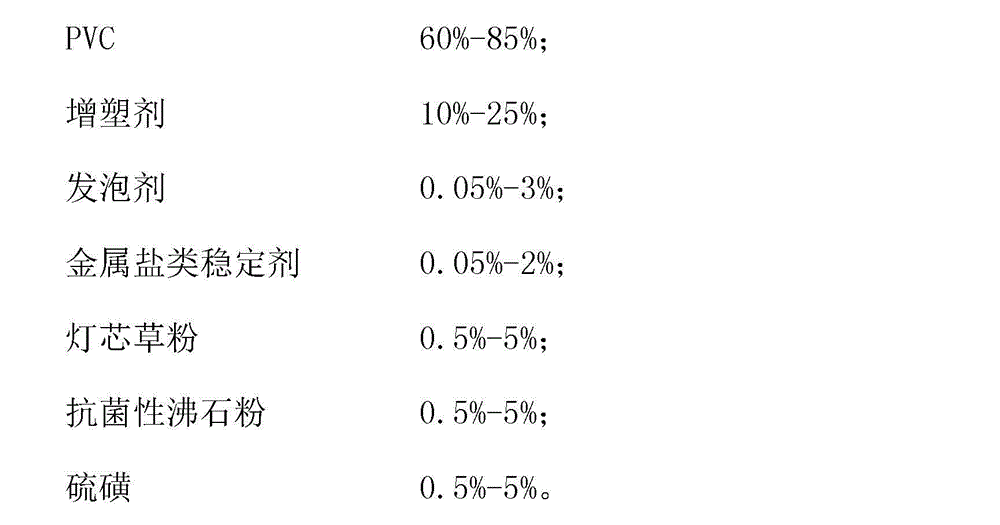

[0014] A kind of antibacterial and deodorizing PVC foam sole material comprises by weight percentage:

[0015]

[0016] The preparation method is as follows:

[0017] (1) Accurately weigh according to the formula, fully mix PVC, DOP, and barium stearate into a drying oven at 100-110°C for pre-plasticization, and stir once every 5 minutes to make DOP completely absorbed by PVC. A pre-plasticized mixture is obtained.

[0018] (2) Put it into a double-roller plastic mixer (roller temperature is 110-120°C). After the material is completely wrapped and plasticized, add other additives and mix evenly, and knead to produce tablets.

[0019] (3) Take the material sheet and place it in a heating mold at 165°C, press it under the condition of 10MPa to make it foam, and cool it out of the mold to obtain an antibacterial and deodorizing PVC foam sole material.

Embodiment 2

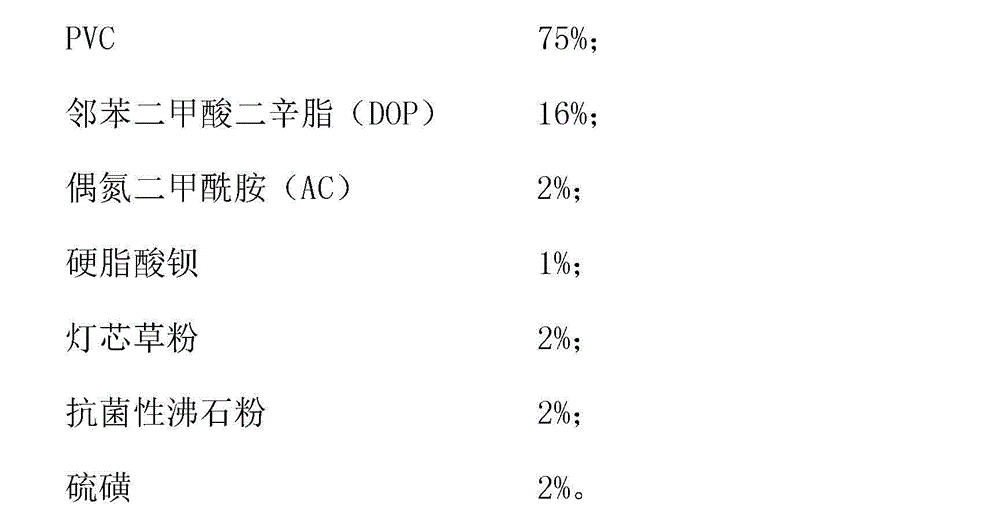

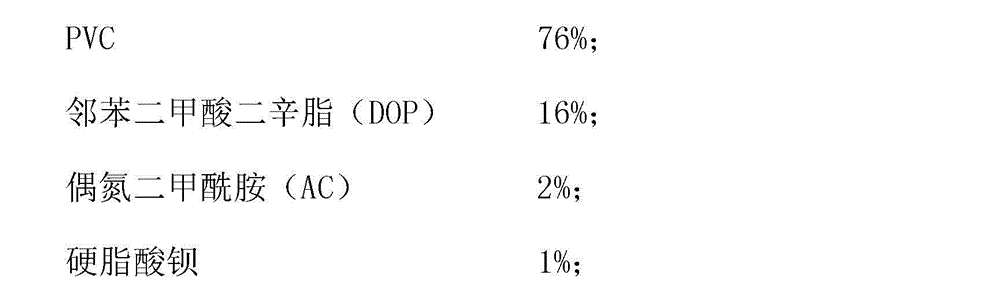

[0021] A kind of antibacterial and deodorizing PVC foam sole material comprises by weight percentage:

[0022]

[0023]

[0024] The preparation method is as follows:

[0025] (1) Accurately weigh according to the formula, fully mix PVC, DBP, and barium stearate into a drying oven at 100-110°C for pre-plasticization, and stir once every 5 minutes to make DBP completely absorbed by PVC. A pre-plasticized mixture is obtained.

[0026] (2) Put it into a double-roller plastic mixer (roller temperature is 110-120°C). After the material is completely wrapped and plasticized, add other additives and mix evenly, and knead to produce tablets.

[0027] (3) Take the material sheet and place it in a heating mold at 165°C, press it under the condition of 10MPa to make it foam, and cool it out of the mold to obtain an antibacterial and deodorizing PVC foam sole material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com