Starch microsphere and preparation method thereof

A technology of starch microspheres and amylase, which is applied in fermentation and other directions, can solve the problems of low porosity and unstable porous structure, and achieve the effect of large porosity, stable porous structure and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

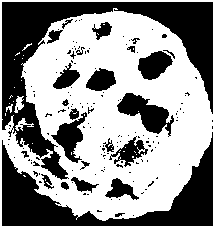

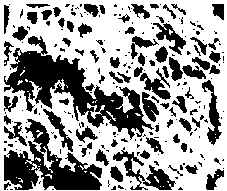

Image

Examples

Embodiment 1

[0042] A kind of starch microsphere, calculated by mass parts, its raw material composition and content are as follows:

[0043] Waxy corn starch 3.04 parts

[0044] Glucoamylase 0.010 parts

[0045] α-amylase 0.001 parts

[0046] Anhydrous calcium chloride 0.0015 parts

[0047] Citric acid 0.09 parts

[0048] Disodium hydrogen phosphate 0.06 parts

[0049] N'N-methylenebisacrylamide 0.32 parts

[0050] Cerium ammonium nitrate 0.017 parts

[0051] Division 60 0.489 parts

[0052] Tween 60 0.326 parts

[0053] Chloroform 24.13 parts

[0054] Cyclohexane 58.80 parts

[0055] 21.05 parts of deionized water.

[0056] The preparation method of above-mentioned a kind of starch microspheres specifically comprises the following steps:

[0057] (1) Add 3.04 parts of waxy corn starch, 0.010 parts of glucoamylase, 0.001 parts of α-amylase and 0.0015 parts of calcium chloride to the mixture prepared by 0.09 parts of citric acid, 0.06 parts of disodium hydrogen phosphate and 6.3...

Embodiment 2

[0063] A kind of starch microsphere, calculated by mass parts, its raw material composition and content are as follows:

[0064] Waxy corn starch 3.20 parts

[0065] Glucoamylase 0.027 part

[0066] α-amylase 0.020 parts

[0067] Anhydrous calcium chloride 0.0017 parts

[0068] 0.12 parts of citric acid

[0069] Disodium hydrogen phosphate 0.02 parts

[0070] N'N-methylenebisacrylamide 0.07 parts

[0071] Cerium ammonium nitrate 0.181 parts

[0072] Span 60 0.484 copies

[0073] Tween 60 0.322 parts

[0074] Chloroform 23.89 parts

[0075] Cyclohexane 50.30 parts

[0076] 20.85 parts of deionized water.

[0077] The preparation method of above-mentioned a kind of starch microspheres specifically comprises the following steps:

[0078] (1) Add 3.20 parts of waxy corn starch, 0.027 parts of glucoamylase, 0.020 parts of α-amylase and 0.0017 parts of calcium chloride to the mixture prepared by 0.12 parts of citric acid, 0.02 parts of disodium hydrogen phosphate and 6.32...

Embodiment 3

[0084] A kind of starch microsphere, calculated by mass parts, its raw material composition and content are as follows:

[0085] Waxy corn starch 3.35 parts

[0086] Glucoamylase 0.027 part

[0087] α-amylase 0.020 parts

[0088] Anhydrous calcium chloride 0.0017 parts

[0089] 0.12 parts of citric acid

[0090] Disodium hydrogen phosphate 0.02 parts

[0091] N'N-methylenebisacrylamide 0.15 parts

[0092] Cerium ammonium nitrate 0.014 parts

[0093] Span 60 0.484 copies

[0094] Tween 60 0.322 parts

[0095] Chloroform 23.89 parts

[0096] Cyclohexane 50.30 parts

[0097] 20.85 parts of deionized water.

[0098] The preparation method of above-mentioned a kind of starch microspheres specifically comprises the following steps:

[0099] (1) Add 3.35 parts of waxy corn starch, 0.027 parts of glucoamylase, 0.020 parts of α-amylase and 0.0017 parts of calcium chloride to the mixture prepared by 0.12 parts of citric acid, 0.02 parts of disodium hydrogen phosphate and 6.32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com