Apparatus and method for preparing olefin from methanol

A technology of methanol to olefins and reactors, which is applied in petrochemical equipment and olefins production fields, can solve the problems of expensive catalysts, high catalyst unit consumption, and affecting the economic benefits of olefins equipment, achieve reasonable and uniform reaction conditions, and solve reaction selectivity Low, the effect of reducing the amount of catalyst carried

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

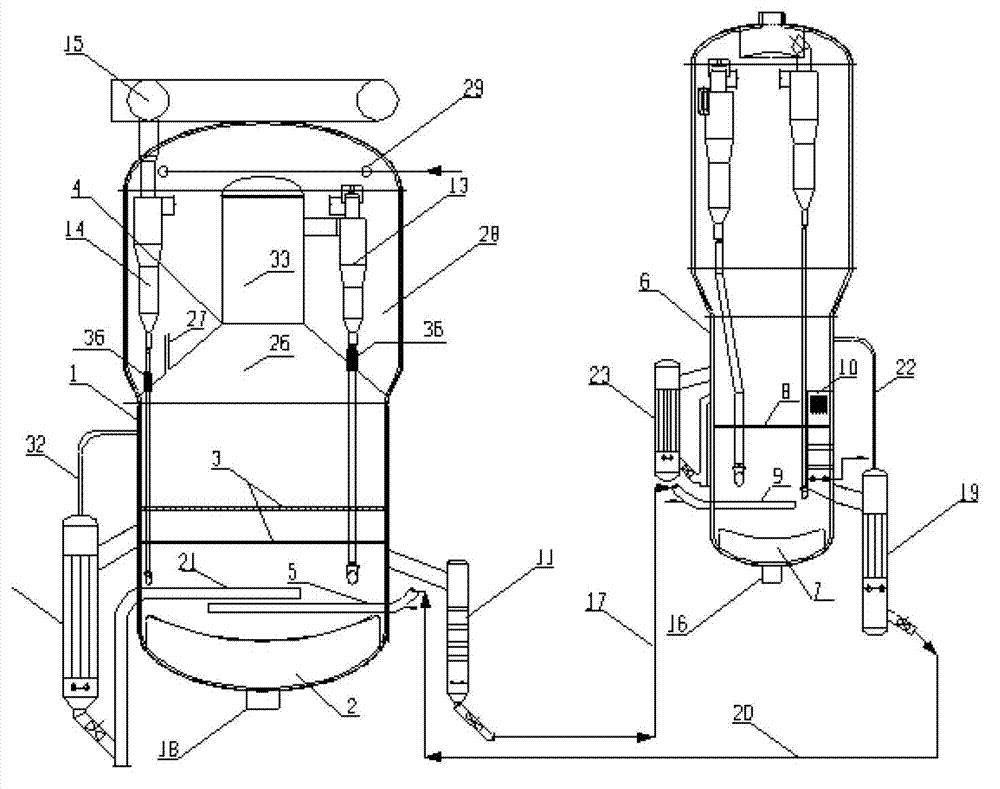

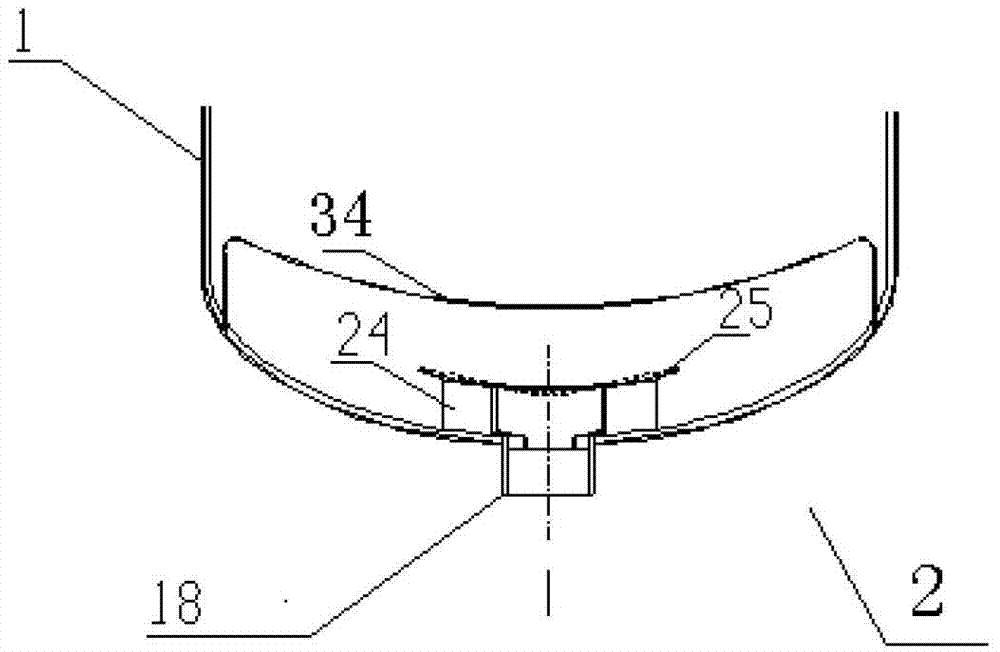

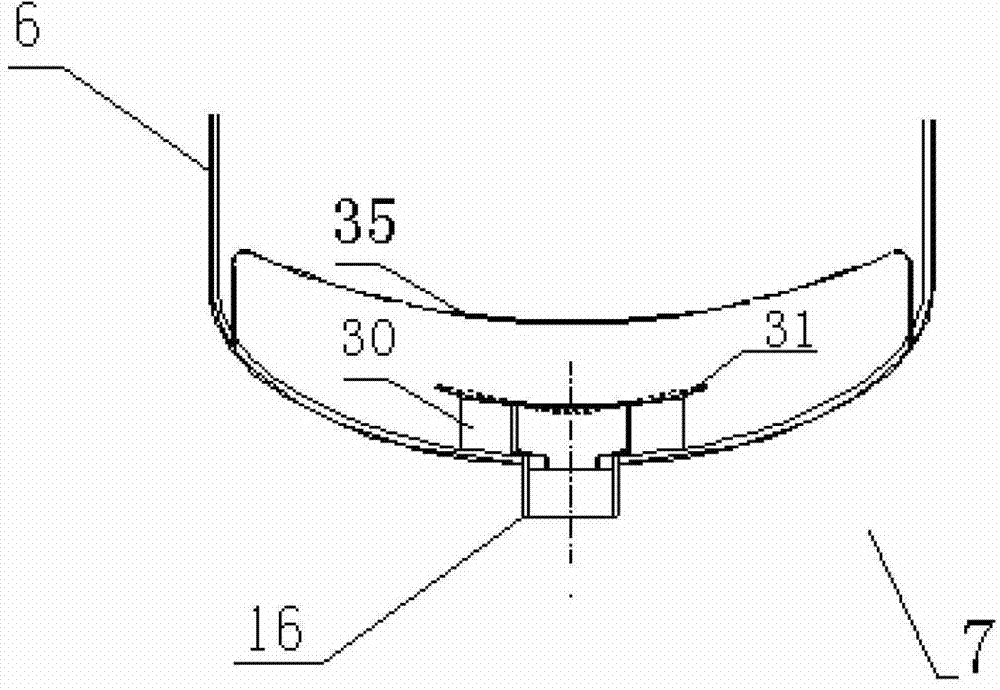

Embodiment 1

[0039] The methanol raw material is preheated to 170°C and enters the bottom of the reactor 1 bed. After the regenerated catalyst passes through the regenerated catalyst stripping section 10 and the regenerator cold cycle external heat extractor 19, it is distributed by the distributor 5 branched outside the cold regenerated catalyst In the lower part of reactor 1; under the conditions of reaction temperature 450°C and reaction pressure 0.2MPa(G), the methanol raw material contacts with the regenerated catalyst and reacts to generate a reaction gas rich in low-carbon olefins, and the excess heat of the reaction is taken from outside the reactor The heater 12 is taken away, and the returned cold catalyst is distributed to the middle of the bed of the reactor 1 through the catalyst distributor 21 of the external heater of the reactor; the reaction gas passes through the reactor grid 3 and enters the catalyst and reaction gas separation device 4 to realize the reaction gas Separat...

Embodiment 2

[0041] The production process is the same as that of Example 1, except that the methanol raw material is preheated to 200°C, the reaction temperature is controlled at 475°C, the reaction pressure is controlled at 0.1MPa (G), the regeneration temperature is controlled at 650°C, and the regeneration pressure is controlled at 0.08MPa (G), the mass space velocity of the reaction is controlled at 5h-1, and the temperature of the regenerated catalyst after cooling is 400°C (see Table 1). The test operation effect shows that the methanol conversion rate is 99.95%, the ethylene+propylene selectivity is 81%, the coke formation rate is 1.82%, and the catalyst unit consumption is 0.8kg / t ethylene+propylene (see Table 2).

Embodiment 3

[0043] The production process is the same as that of Example 1, except that the methanol raw material is preheated to 250°C, the reaction temperature is controlled at 490°C, the reaction pressure is controlled at 0.05MPa (G), the regeneration temperature is controlled at 640°C, and the regeneration pressure is controlled at 0.05MPa (G), the mass space velocity of the reaction is controlled at 2h -1 , the temperature of the regenerated catalyst after cooling is 500°C (see Table 1). The test operation effect shows that the methanol conversion rate is 99.97%, the ethylene+propylene selectivity is 80.5%, the coke formation rate is 1.8%, and the catalyst unit consumption is 0.8kg / t ethylene+propylene (see Table 2).

[0044] Table 1

[0045] operating parameters

Example 1

Example 2

Example 3

Methanol preheating temperature

170℃

200℃

250℃

temperature reflex

450℃

475℃

490℃

reaction pressure

0.2MPa(G)

0.1Mpa (G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com