processing container

A technology for processing containers and boxes, which is applied to used abrasive processing devices, abrasives, metal processing equipment, etc., can solve the problems of soft resin liner damage, seal leakage, easy hardening, etc., and achieve improved sealing and durability performance, ensuring the sealing state, and the effect of easy packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

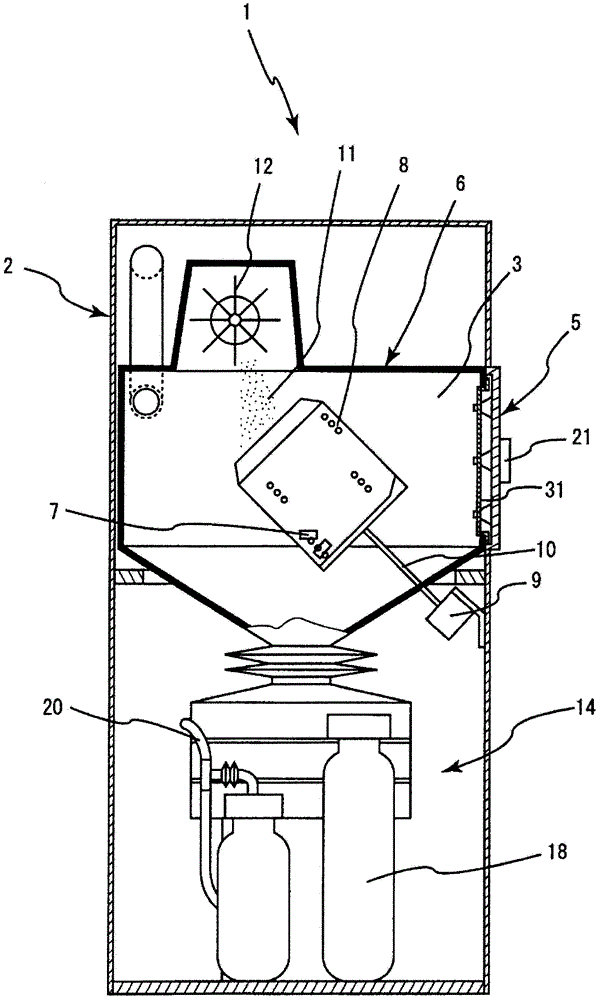

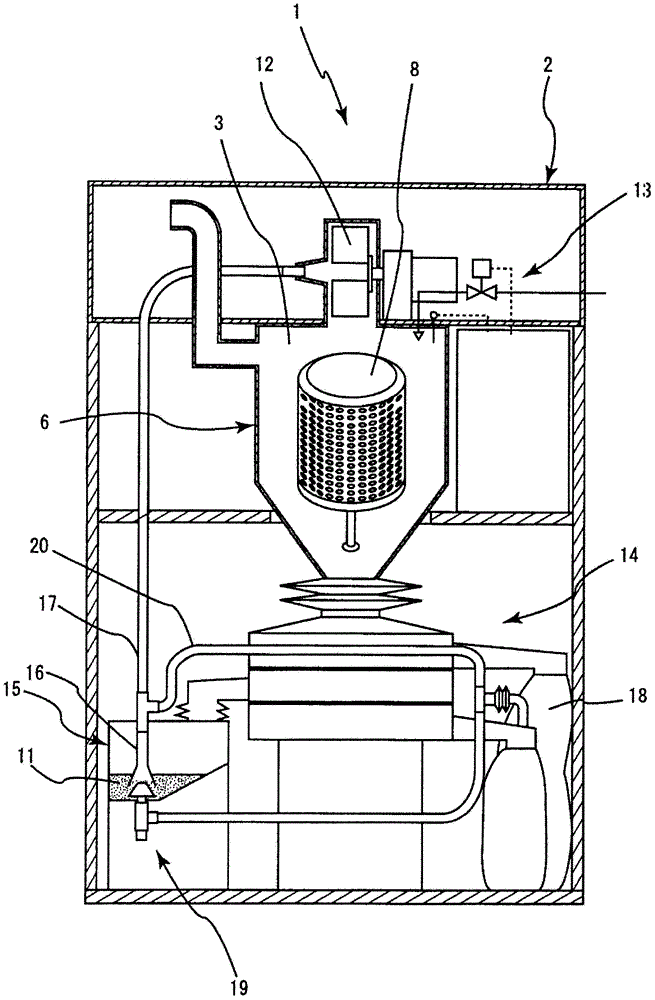

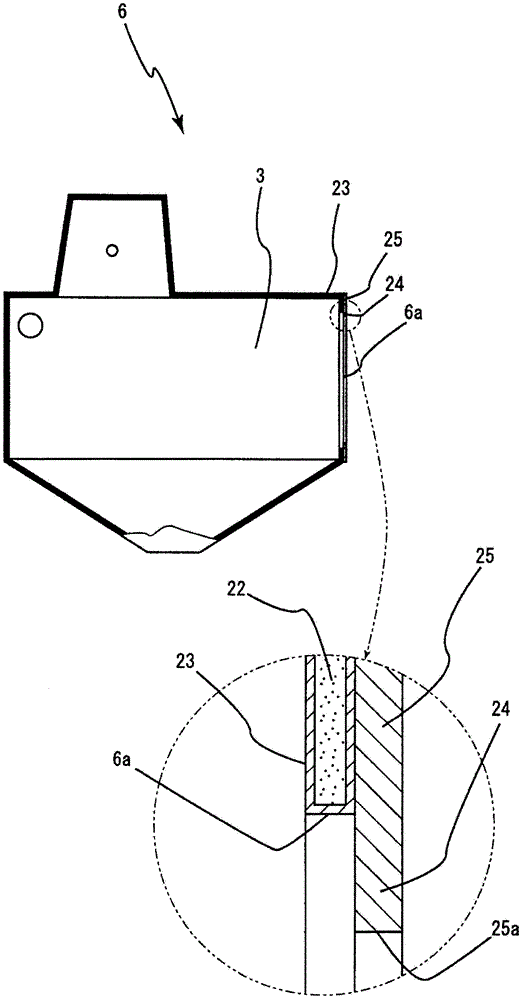

[0053] Hereinafter, the present invention will be described in detail using the modes for implementing the present invention shown in the drawings.

[0054] Figure 1 to Figure 8 Shown in the 1st mode for implementing the present invention, 1 is to use the shot blasting device of the present invention, and this shot blasting device 1 comprises: Machine frame 2; The upper part of frame 2 is formed with the spray treatment chamber 3 that the bottom surface is funnel-shaped, has the opening and closing door 5 that hinge part 4 is installed; The assembled and disassembled motor 9 drives the bucket 8 supporting the formed part 7 for deburring; the projection machine 12 is supported on the bucket support 10 installed on the top of the spray treatment box 6, and the projection material 11 is projected onto the formed part 7 for removing burrs; a refrigerant supply device 13, which supplies refrigerant into the spray treatment box 6; a screening device 14, which is installed in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com