General filter membrane cartridge assembly and its structure

A filter membrane and filter element technology, applied in the field of general filter membrane filter element components, can solve the problems of decreased filtration accuracy, increased membrane porosity, scrapped membrane elements, etc., and achieves the effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

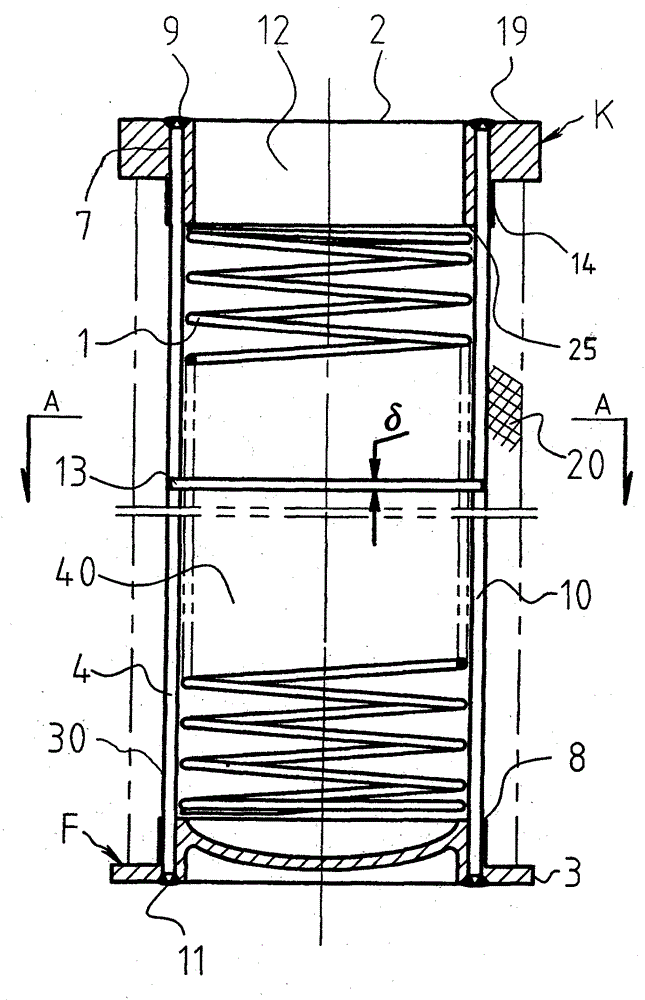

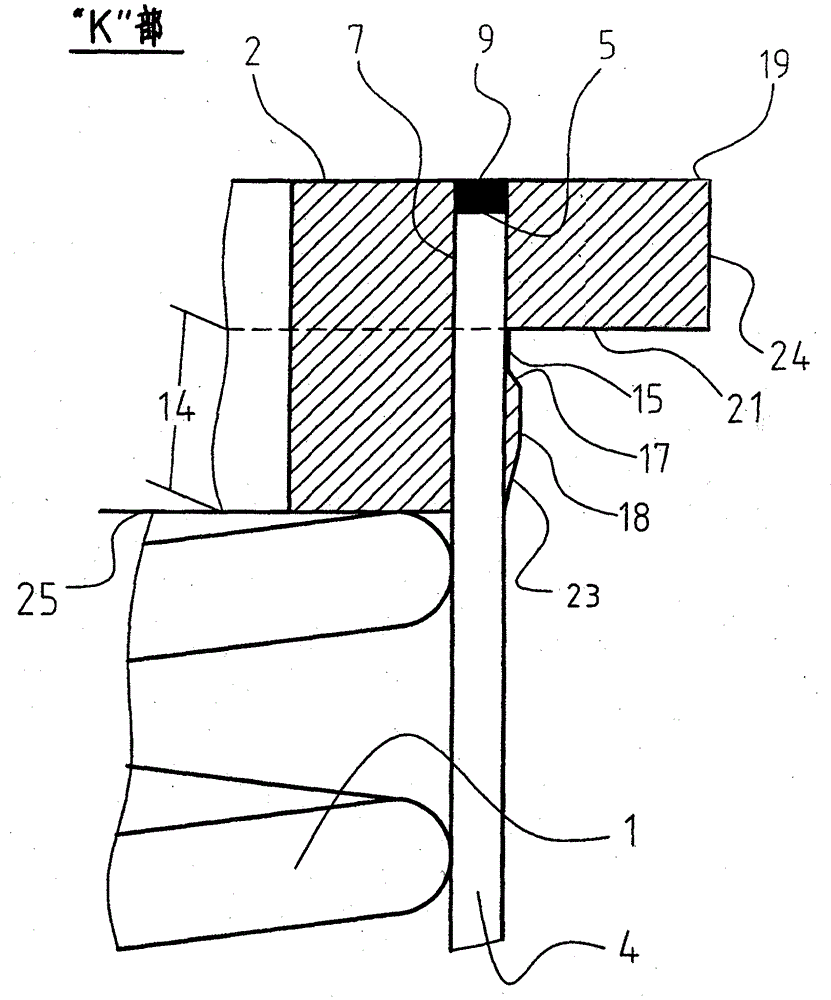

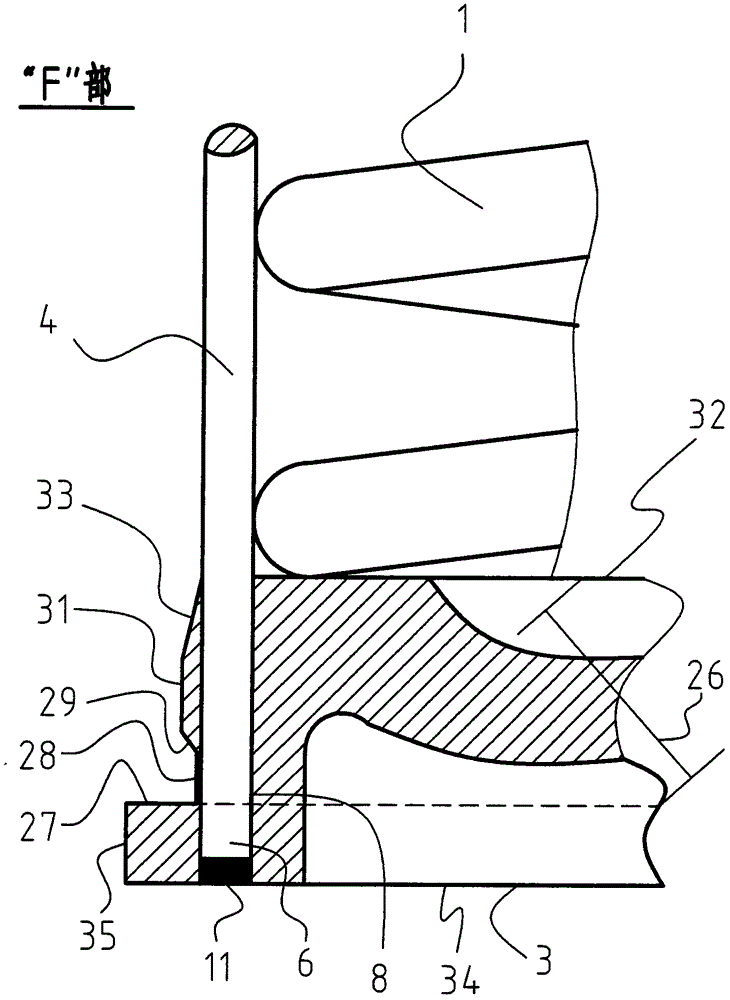

[0016] According to the above-mentioned universal filtration membrane filter element assembly structure of the present invention, a kind of general filtration membrane filter element assembly and its structure are embodied by the accompanying drawings, according to figure 1 The universal filtration membrane element assembly of the present invention is to use the cylindrical helical support spring 1 of the intermediate device as the support body, install the filter element head 2 at one end of the support spring 1, and install the filter element end cover at the other end of the support spring 1 3, and the support rod 4 is evenly arranged around the outer periphery of the support spring 1 in the axial direction. When the support rod 4 surrounds the support spring 1 in the fence formed by the support rod 4, the upper end of the support rod 4 The fixed end 9 is installed in the device hole 6 of the filter element head 2, the fixed end 11 of the lower end of the support rod 4 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com