Clamp conveying type plastic film residue recycling machine with field straw chopping and returning function

A straw pulverization, clamping and conveying technology, applied in collectors, harvesters, crop processors, etc., can solve the problems of difficult recovery of residual film, high impurity content of residual film, low operation efficiency, etc., and achieve the effect of stripping. Ideal, high residual film recovery rate, high operating speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

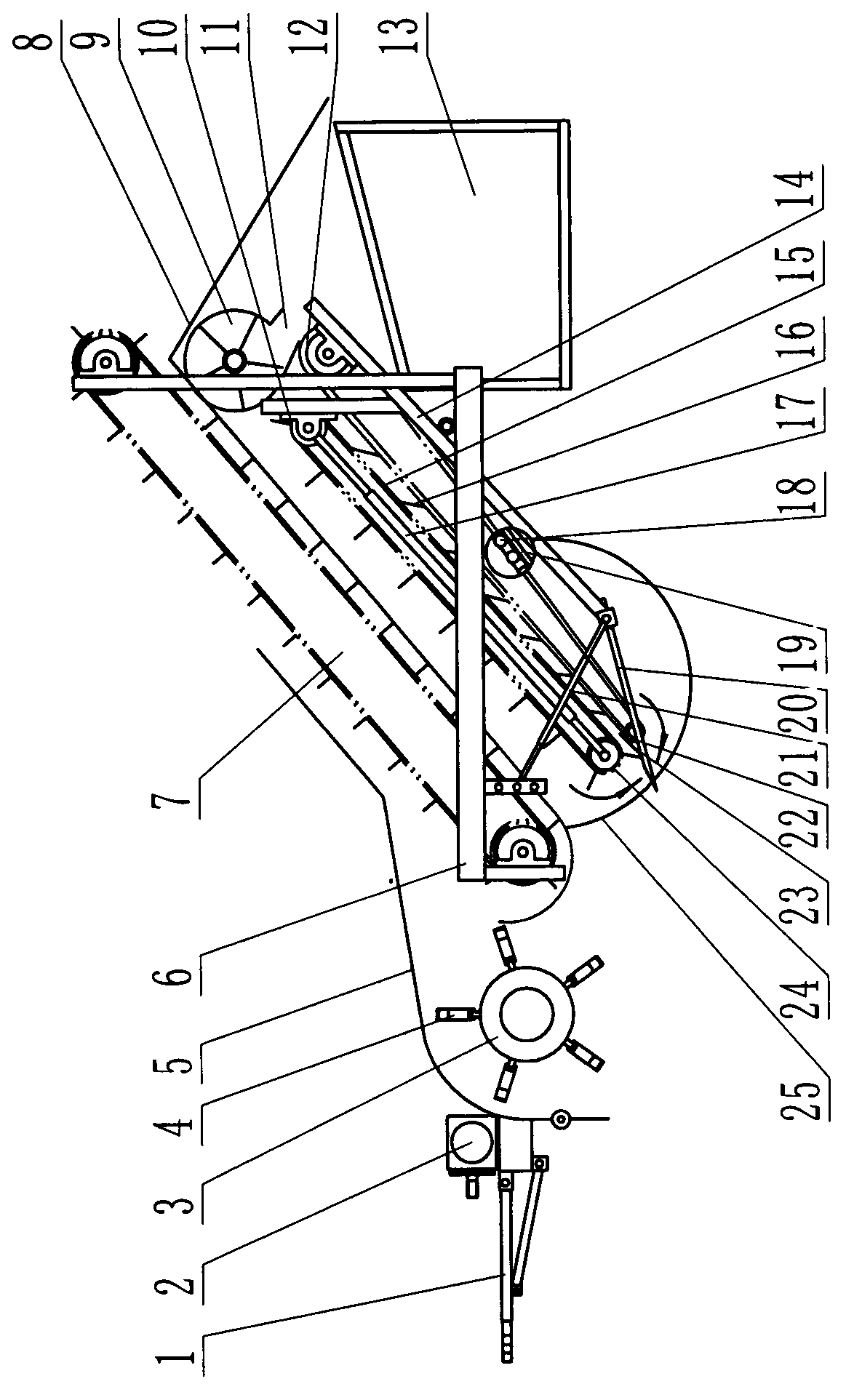

[0014] refer to figure 1 , is an embodiment of a straw crushing and returning to the field and clamping conveying type residual film recovery machine, including a traction device (1), a transmission system (2), a frame (6), a residual film box (13), and a walking wheel ( 25), straw crushing device, straw conveying device (7), residual film recovery device and film stripping device, the traction device (1) is arranged on the front side of the straw crushing device, and the straw conveying device (7) is arranged on the straw crushing device On the rear side, the tail slide plate (8) is arranged on the rear side of the straw conveying device (7), the residual film recycling device is arranged on the lower side of the straw conveying device (7), and the residual film box (13) is arranged behind the residual film recycling device Side, road wheel (25) is located on the frame (6). The straw crushing device is composed of a cutter shaft (3), a blade (4) and a shield (5), the blade (...

Embodiment 2

[0016] The difference between this embodiment and Embodiment 1 is that the clamping plate (16) of the residual film recovery device is toothed.

Embodiment 3

[0018] The difference between this embodiment and Embodiment 1 is that the tuyere (11) of the stripping device is arranged on the lower side of the conveying driving sprocket (12).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com