Heatable fluid line, use thereof and method for producing same

A technology of fluid conduit and heating conductor, applied in the direction of heating element shape, ohmic resistance heating, pipeline heating/cooling, etc., can solve the problems of insufficient isolation of the pipe body, high connection cost, etc., and achieve the effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] For the foregoing and especially the following description, it should be clearly emphasized that the present invention is not limited to the embodiments and is not limited to all or more features of the combination of technical features described here. Rather, this / each embodiment Each individual component feature (for example, referred to as a favorable parameter range for a particular material) can also be disconnected from all other features, thereby, the component feature itself and any other embodiment. Combinations of features are all inventive.

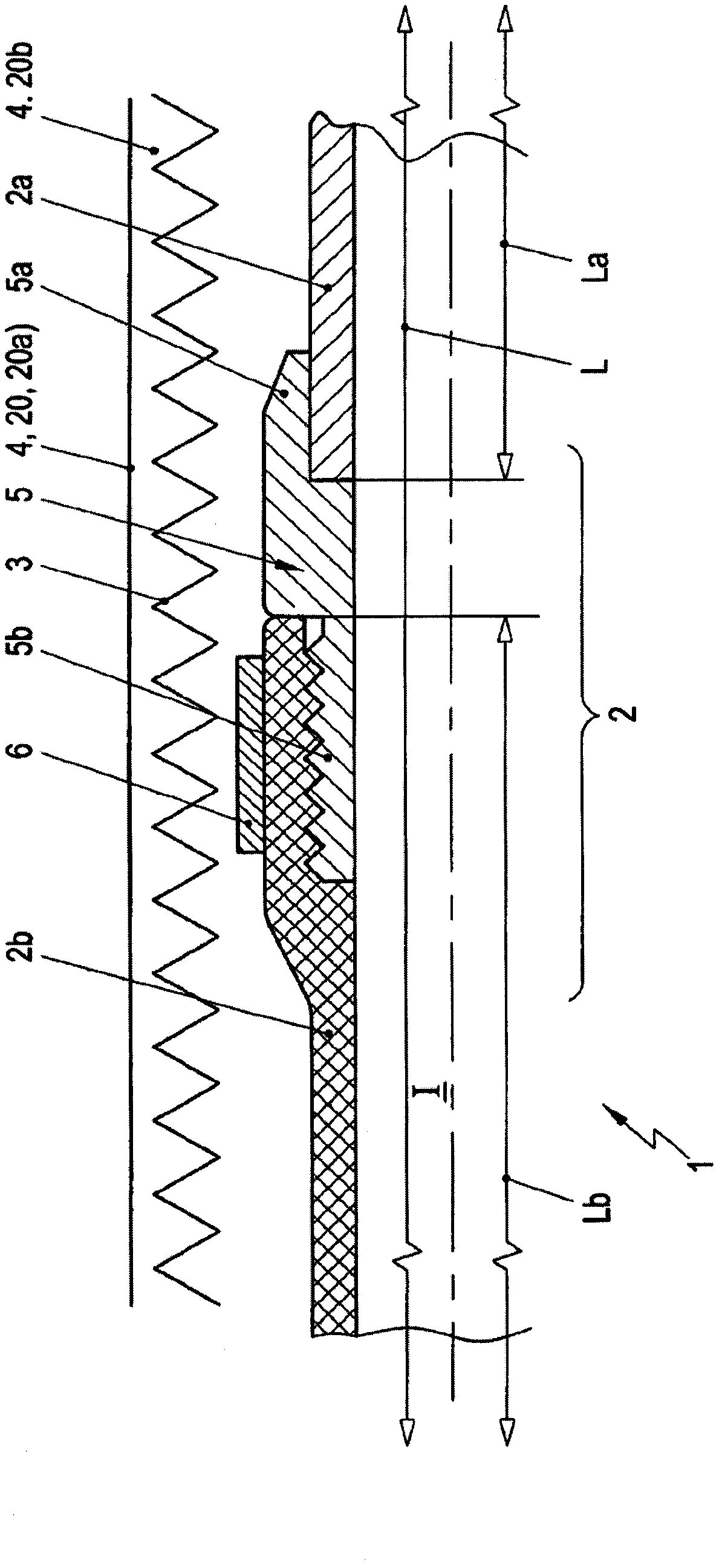

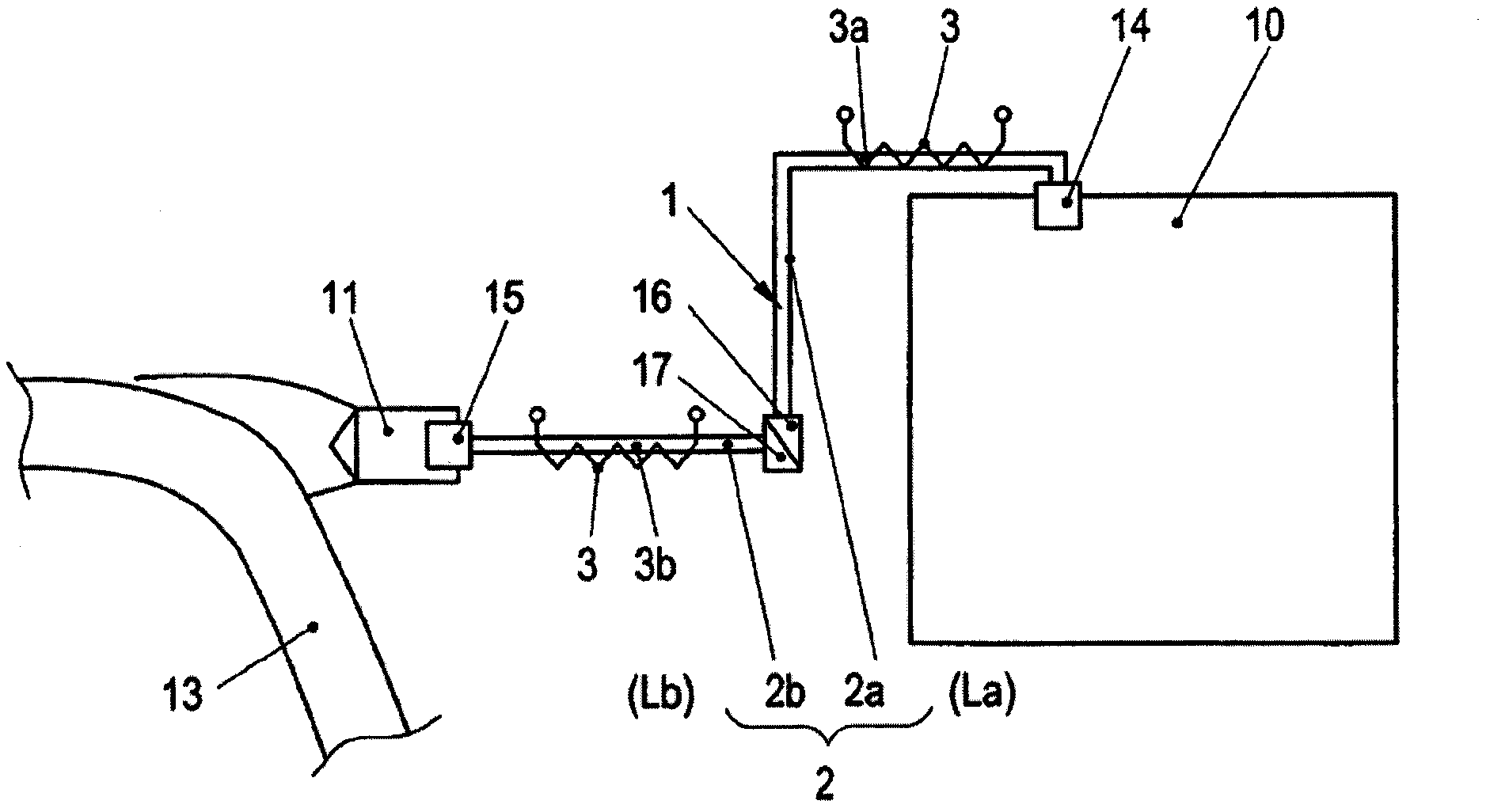

[0062] as first by figure 1 As follows, the heatable fluid conduit 1 according to the invention has at least one line 2 and at least one electrically heating conductor 3 extending at least over a partial region of the length L of the line. The heating conductor 3 , which may in particular be a stranded wire, is only shown as a highly simplified zigzag line. The heating conductor can surround the cylindrical surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com