Low-grade coal slurry production method, low-rade coal slurry production device, and low-grade coal gasification system

A technology of low-grade coal and manufacturing method, which can be applied in the manufacture of combustible gas, gasification process, granular/powder fuel gasification, etc., and can solve problems such as decreased energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

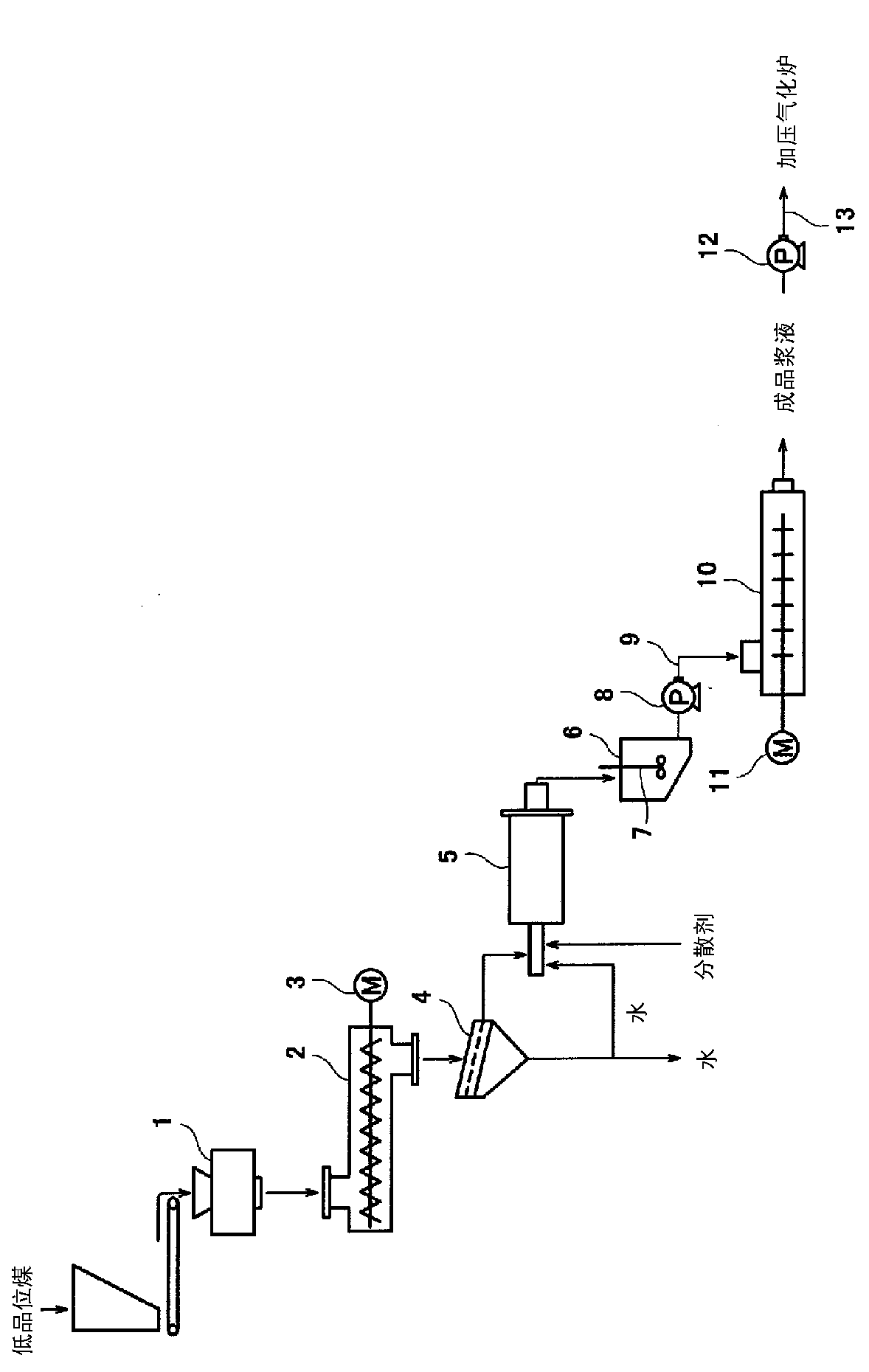

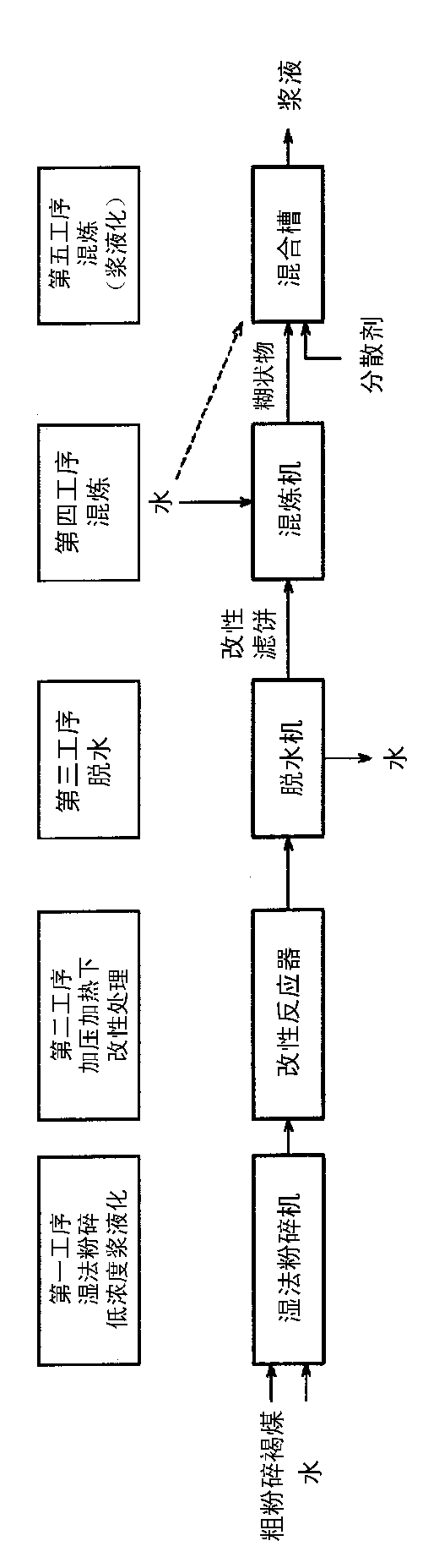

[0060] (first process)

[0061] The lignite (Loy Yang lignite) of the properties shown in Table 1 was coarsely pulverized using a jaw crusher so that particles with a particle size of 3 mm or less were 90% by weight or more (passed through a sieve with a mesh size of 3 mm). The particles are 90% by weight or more of the entire lignite). Water was added to the coarsely pulverized lignite to form a lignite-water mixture with 95% by weight of the lignite. 10 kg of this mixture was put into a high-temperature and high-pressure batch kneader with a volume of about 20 L equipped with a double-arm type kneading blade.

[0062] [Table 1]

[0063] .

[0064] Under the conditions of a pressure of 5.0 MPa and a temperature of 280° C., the lignite-water mixture was kneaded for one hour, and the lignite was subjected to non-evaporative dehydration and modification treatment. After the modification treatment, the lignite-water mixture (kneaded product) in a paste state is taken out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com