Electromagnetic shielding, sealing and waterproofing method for cabin body opening cover of airborne electronic pod

A technology of electromagnetic shielding and conductive sealing strips, which is applied in electromagnetic and protection, electromagnetic shielding and sealing and waterproofing, and mechanical fields. It can solve the problems of uneven surface of the mouth frame, narrow walls, and inability to set grooves, etc., to achieve good sealing and waterproof performance. Adhesive bonding is firm and durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0034] With reference to the above-mentioned drawings, the specific implementation methods of the sealing method of the existing airborne electronic pod cabin body cover and the airborne electronic pod cabin body cover sealing method provided by the present invention are described in detail.

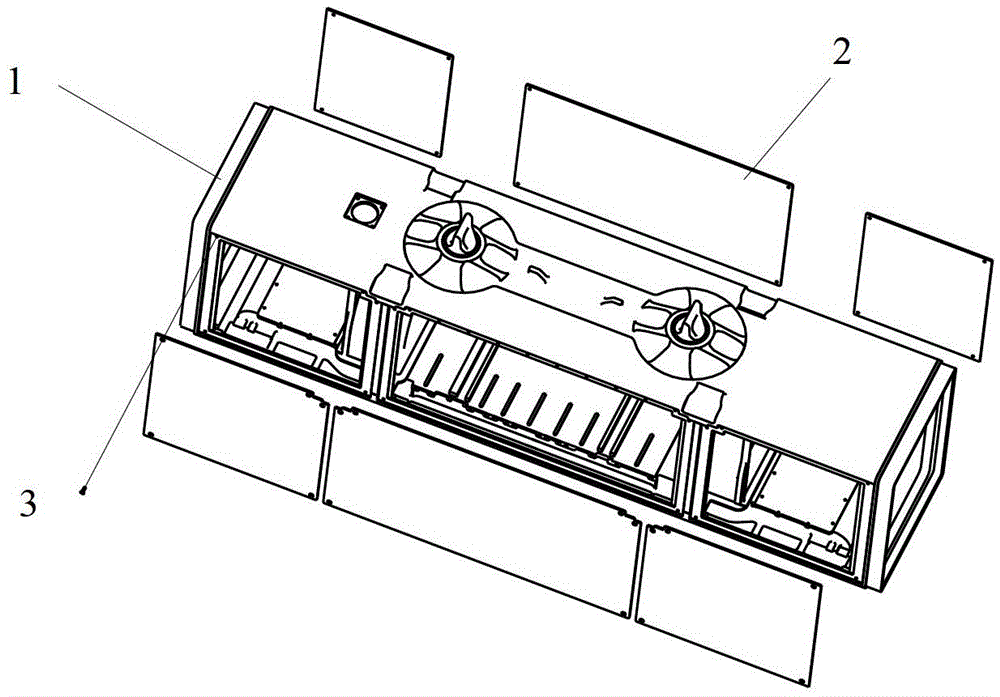

[0035] see figure 1 , the middle section of an airborne electronic pod cabin is composed of a cabin frame 1 and flaps 2 of different sizes and shapes, and the cabin skeleton 1 and flaps 2 of different sizes and shapes are connected by screws 3 made. During sealing installation, the mouth cover 2 is embedded in the mouth frame of the cabin frame 1, and after being tightened with the screw 3, the outer surface of the mouth cover 1 and the outer surface of the cabin frame 1 are on the same plane.

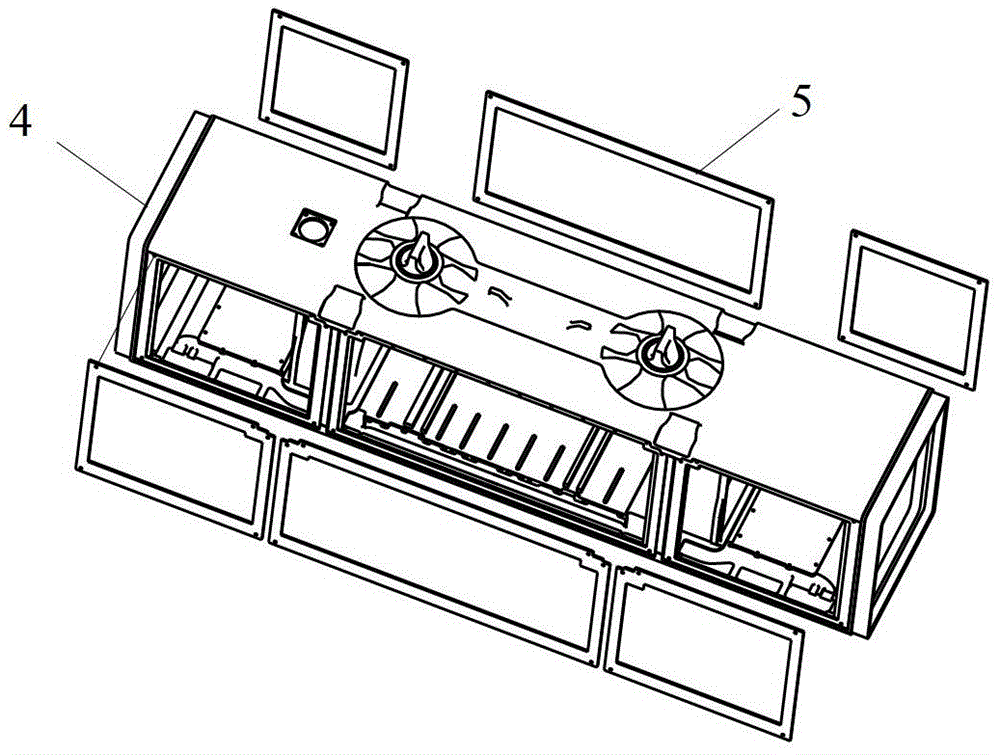

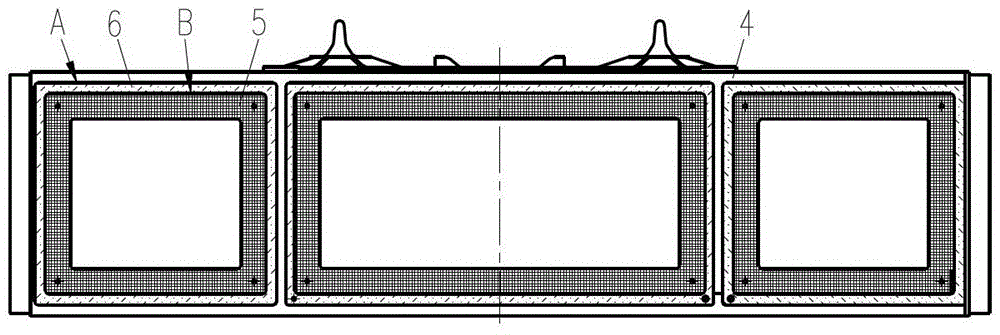

[0036] Sealing of existing methods see figure 2 , be to paste the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com