Magnetic wave instrument magnetic core forming machine

A molding machine and magnetic wave instrument technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem of damaging the thermal insulation film on the surface of the sensor antenna structure, and achieve reasonable design structure, high work efficiency, and mechanical error small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

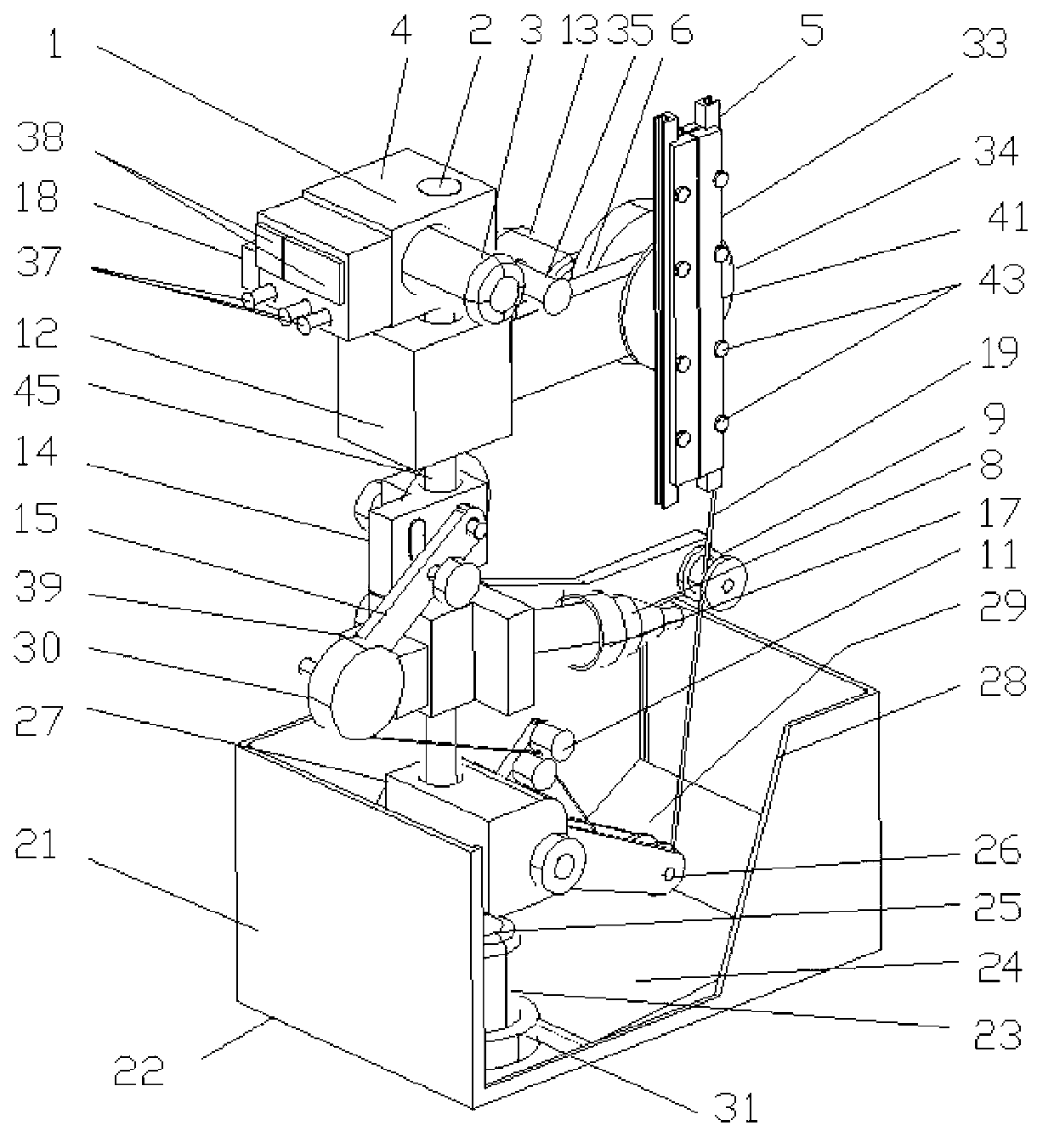

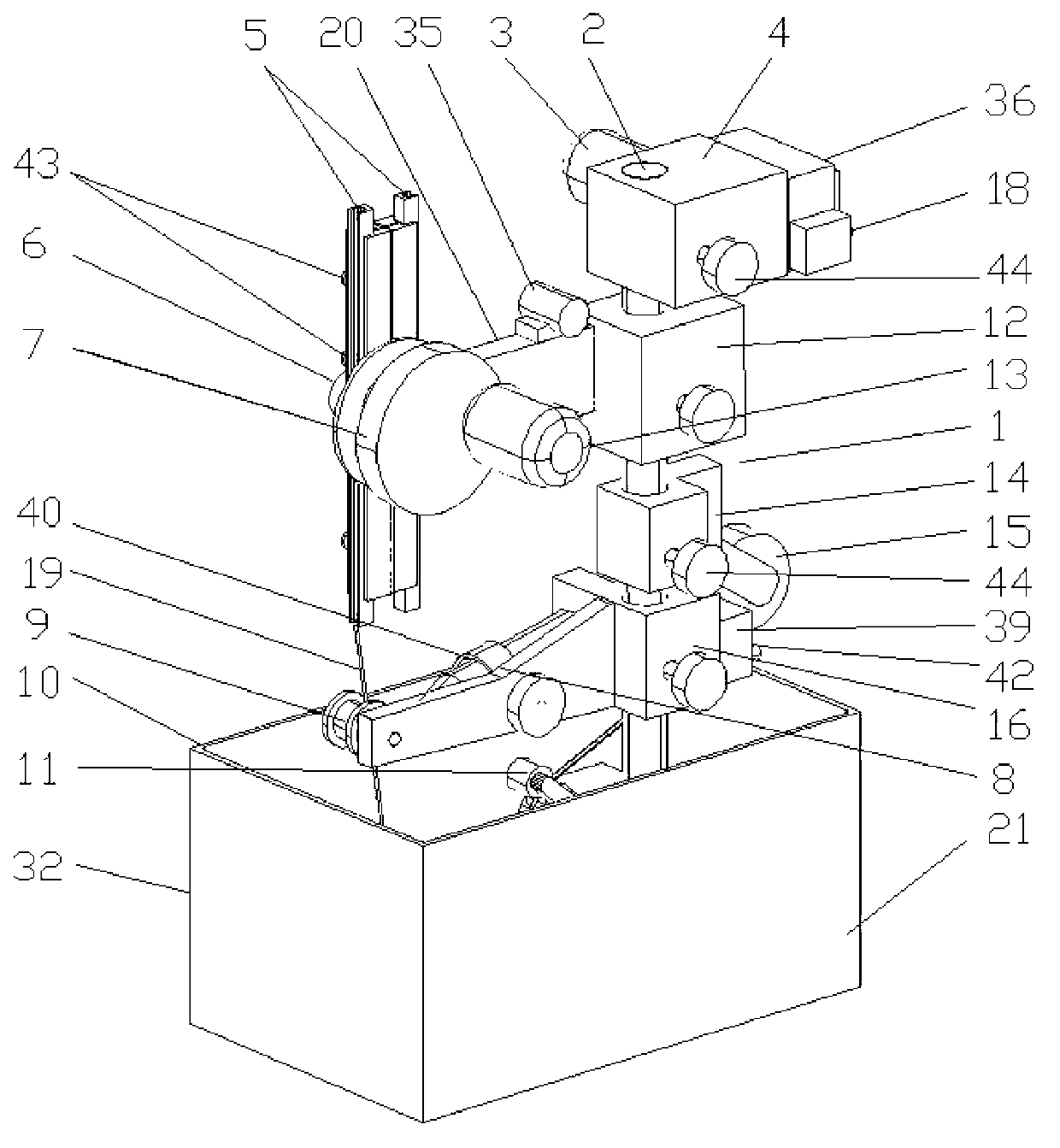

[0059] The magnetic wave instrument magnetic core molding machine of the present invention comprises parts such as rod-shaped magnetic core special-purpose heat treatment forming tank frame assembly device 6, magnetic core diaphragm band coating fluid container groove 21 and thermal drying device 8, such as figure 1 and figure 2 shown.

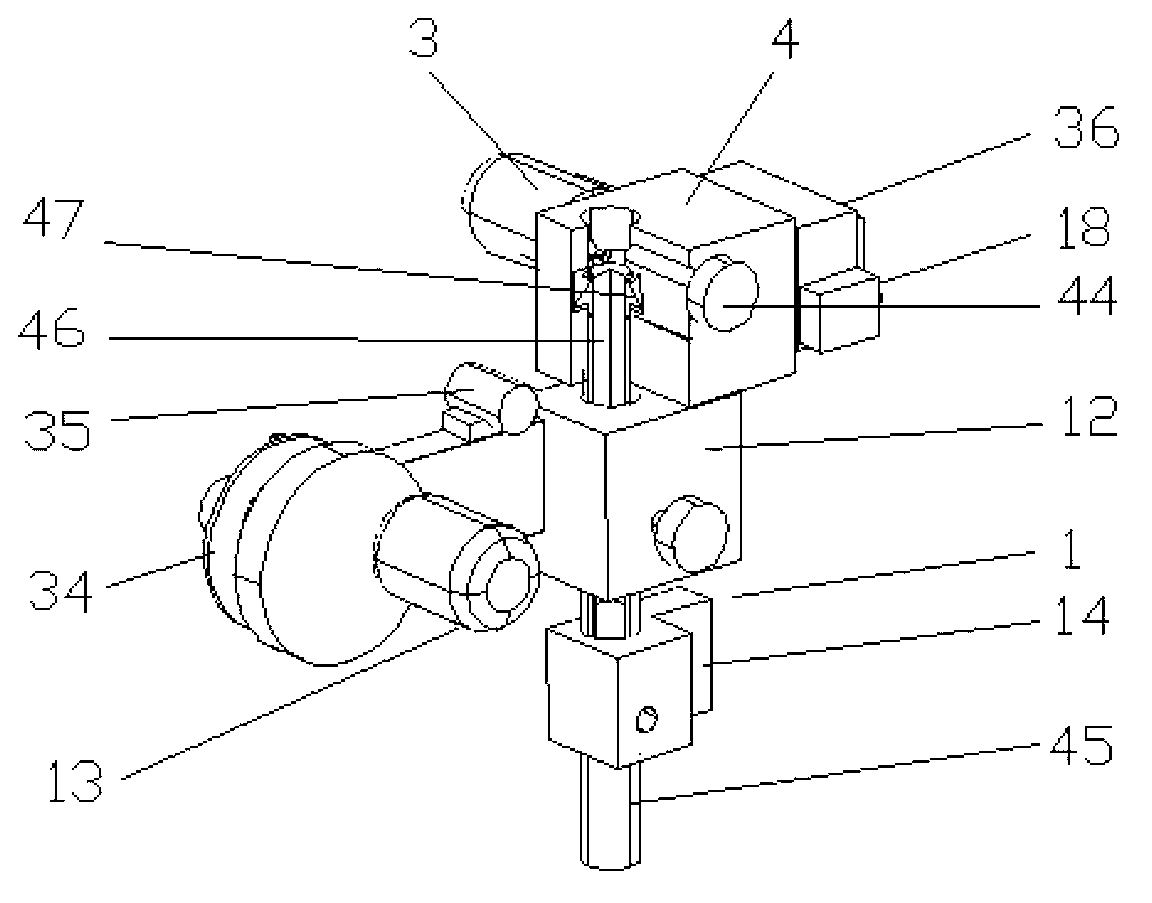

[0060] The magnetic core forming groove frame fixing frame 41 fixed in pairs on the rotating shaft chuck 34 with a diameter of 75 mm has a size of 235 × 78 × 62 mm, and the magnetic core forming groove frame 5 is arranged on the rectangular section of the magnetic core forming groove frame fixing frame 41 In the card slot, the size of the cross section of the card slot is within 32×48 mm, and the length of the card slot is 235 mm, which is 4 / 5 of the length of the magnetic core forming slot frame 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com