Surface modification method for M40J graphite fibers

A surface modification, graphite fiber technology, applied in fiber treatment, textile and papermaking, physical treatment, etc., can solve the problems of difficult surface modification treatment of M40J graphite fiber, less heteroatom content, less relative active points, etc. Interfacial bonding ability, increasing bonding effect, reducing the effect of interfacial stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

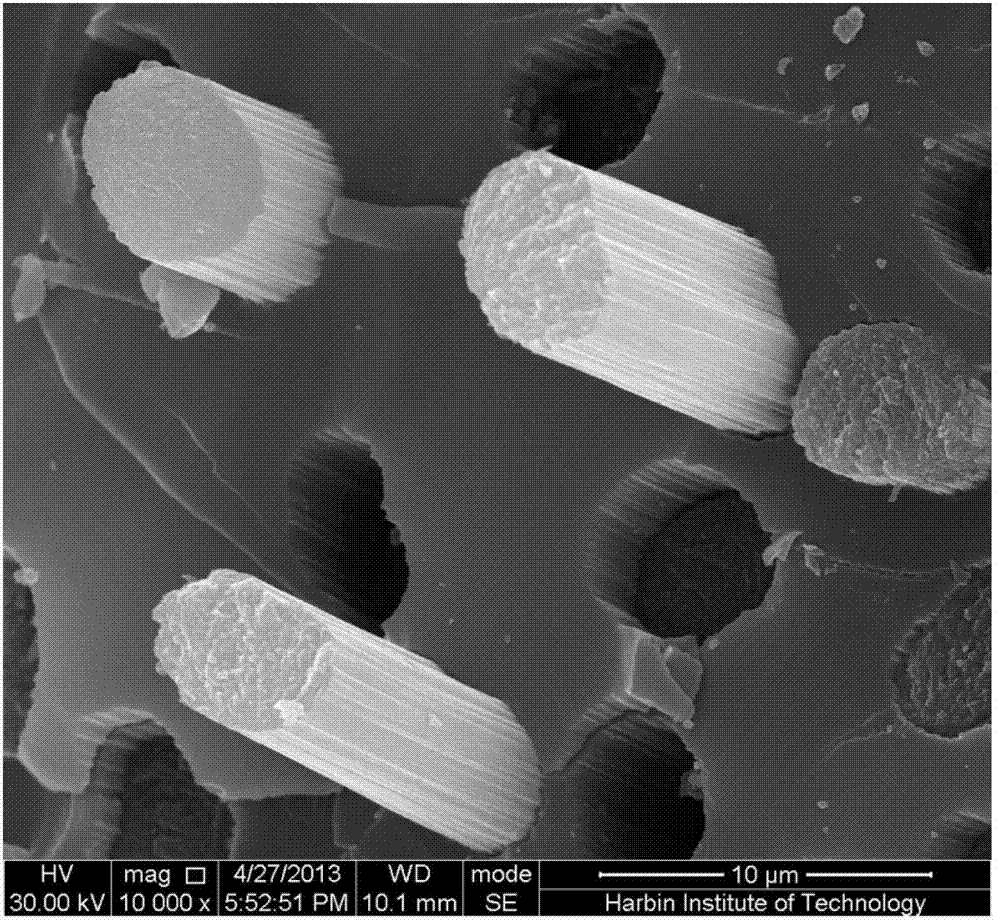

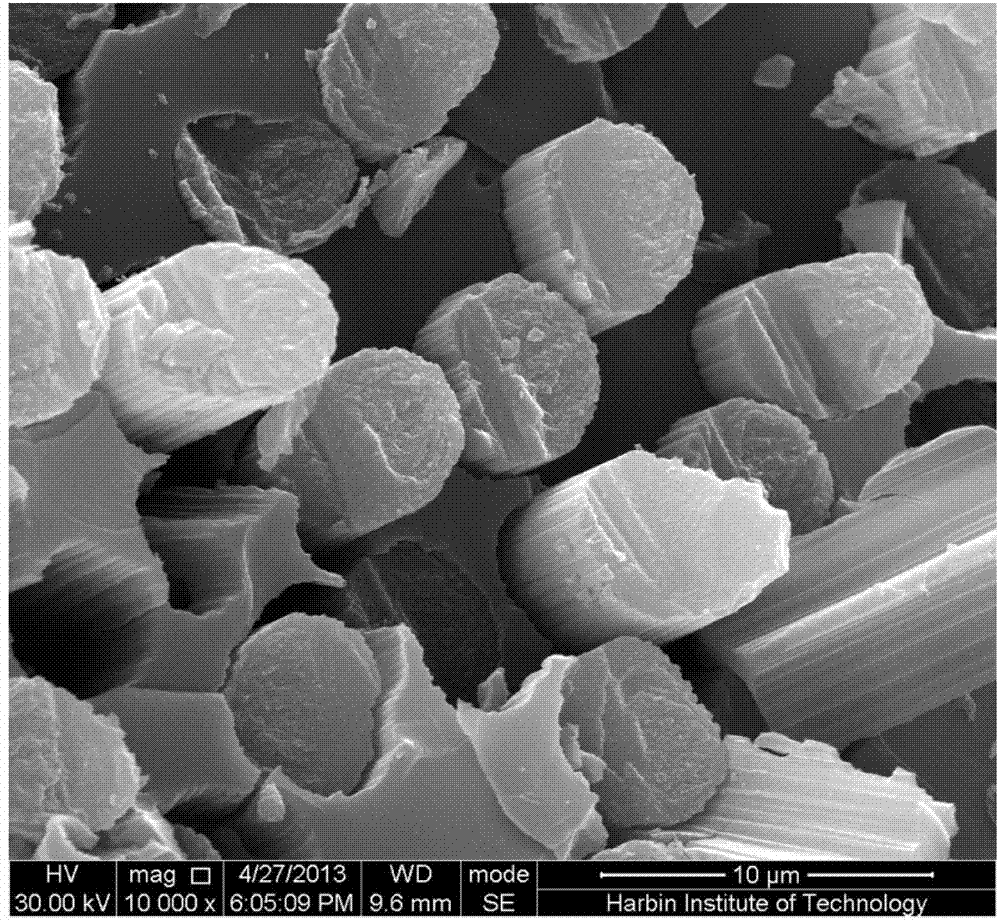

[0022] Specific embodiment one: present embodiment a kind of M40J graphite fiber surface modification method, it is realized by following steps:

[0023] 1. Disperse graphene oxide in E-51 epoxy resin-acetone solution to make slurry;

[0024] 2. Put the M40J graphite fiber into the slurry obtained in step 1 for dip coating;

[0025] 3. The M40J graphite fiber dip-coated in step 2 is irradiated with gamma rays under inert gas or vacuum conditions to complete the surface modification of the M40J graphite fiber;

[0026] Wherein, the mass concentration of graphite oxide in the slurry described in step 1 is 2% to 5%, and the mass concentration of E-51 epoxy resin-acetone solution is 10% to 30%;

[0027] The irradiation dose described in step 3 is 50-100KGy, and the irradiation dose rate is 6.0-10.0KGy / h.

[0028] This embodiment includes the following beneficial effects:

[0029] 1. M40J graphite fiber is a high-modulus and high-strength fiber. Compared with other ordinary fibe...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the gamma rays described in step three are 60 Co gamma-rays. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the irradiation dose in Step 3 is 60-80KGy. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com