Preparation method of molecular colloidal photonic crystal beads

A colloidal photonic crystal and microbead technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as limiting the practical application of colloidal photonic crystal microbeads, and achieve integration and miniaturization, particle size distribution Uniform, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

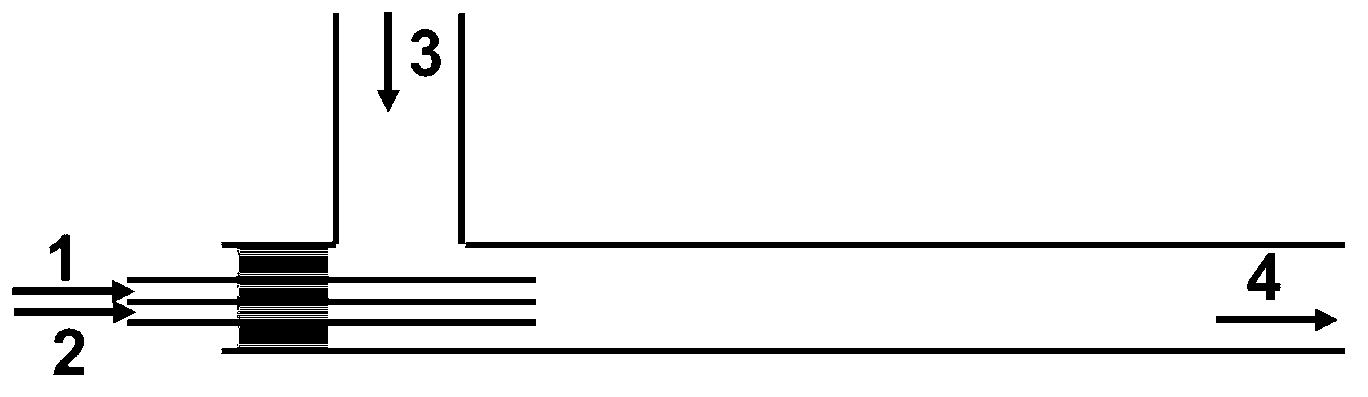

[0034] 1. Configure the dispersion of monodisperse polystyrene microspheres with a particle size of 226nm and a mass fraction of 30% as the first dispersed phase. After the dispersion is sucked into the syringe, it is connected to a micro-injection pump and the flow rate is set at 0.2mL h -1

[0035] 2. Configure the EO3-TMPTA solution mixed with 0.2wt% ferric oxide nanoparticles as the second dispersed phase, draw the solution into the syringe and connect it to a micro-injection pump to set the flow rate to 0.2mL h -1

[0036] 3. Select methyl silicone oil as the continuous phase solution, and connect it to a micro-injection pump after sucking it into a syringe, and set the flow rate to 2mL h -1

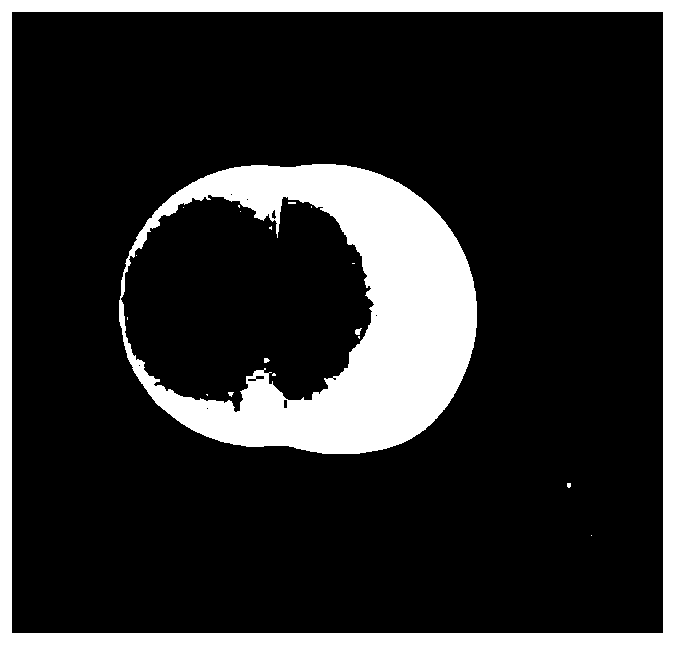

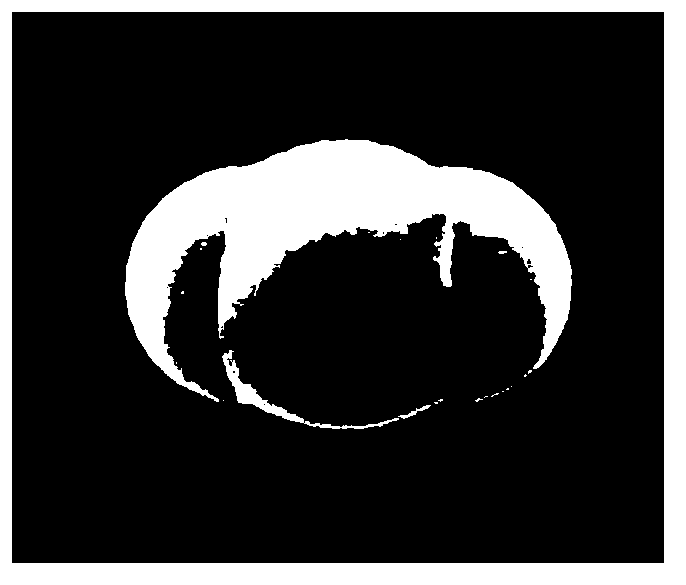

[0037] 4. Start the three-phase microfluidic device: After the continuous phase methyl silicone oil is completely filled with the soft rubber tube, start the injection pumps of the two dispersed phases at the same time. After the flow rate is stable, a stable and uniform droplet t...

Embodiment 2

[0042] 1. Configure the dispersion of monodisperse silica microspheres with a particle size of 300nm and a mass fraction of 30% as the first dispersed phase, draw the dispersion into a syringe and connect it to a micro-injection pump and set the flow rate to 0.2mL h -1

[0043] 2. Configure the EO3-TMPTA solution mixed with 0.2wt% ferric oxide nanoparticles as the second dispersed phase, draw the solution into the syringe and connect it to a micro-injection pump to set the flow rate to 0.2mL h -1

[0044] 3. Select base silicone oil as the continuous phase solution, and connect it to a micro-injection pump after sucking it into a syringe, and set the flow rate to 2mL h -1

[0045] 4. Start the three-phase microfluidic device: After the continuous phase methyl silicone oil is completely filled with the soft rubber tube, start the injection pumps of the two dispersed phases at the same time. After the flow rate is stable, a stable and uniform droplet template with a double-sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com