Novel door body structure of vacuum film plating equipment

A technology of coating equipment and door body, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of many peripheral components and pipelines, affecting the overall appearance of the equipment, high labor intensity, etc., to achieve universal Good performance, convenient layout and hidden pipelines, neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

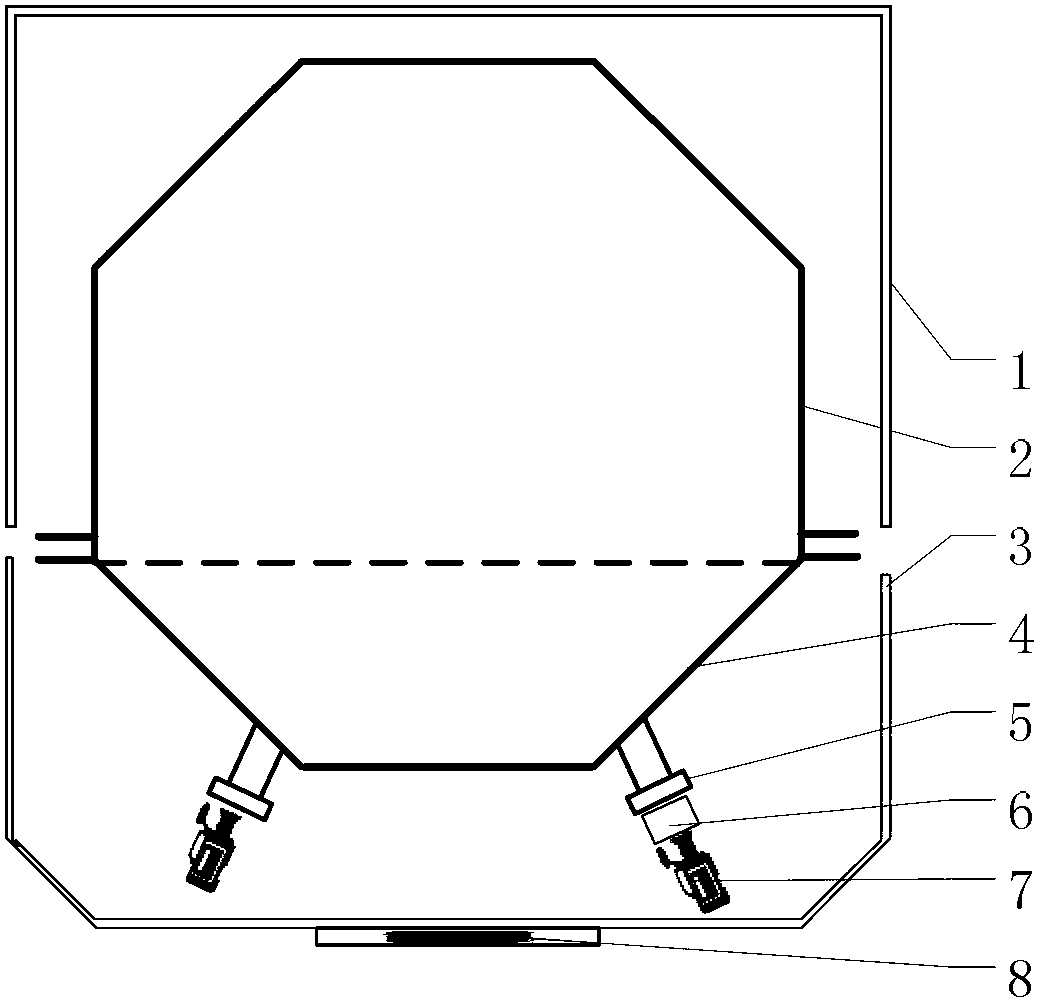

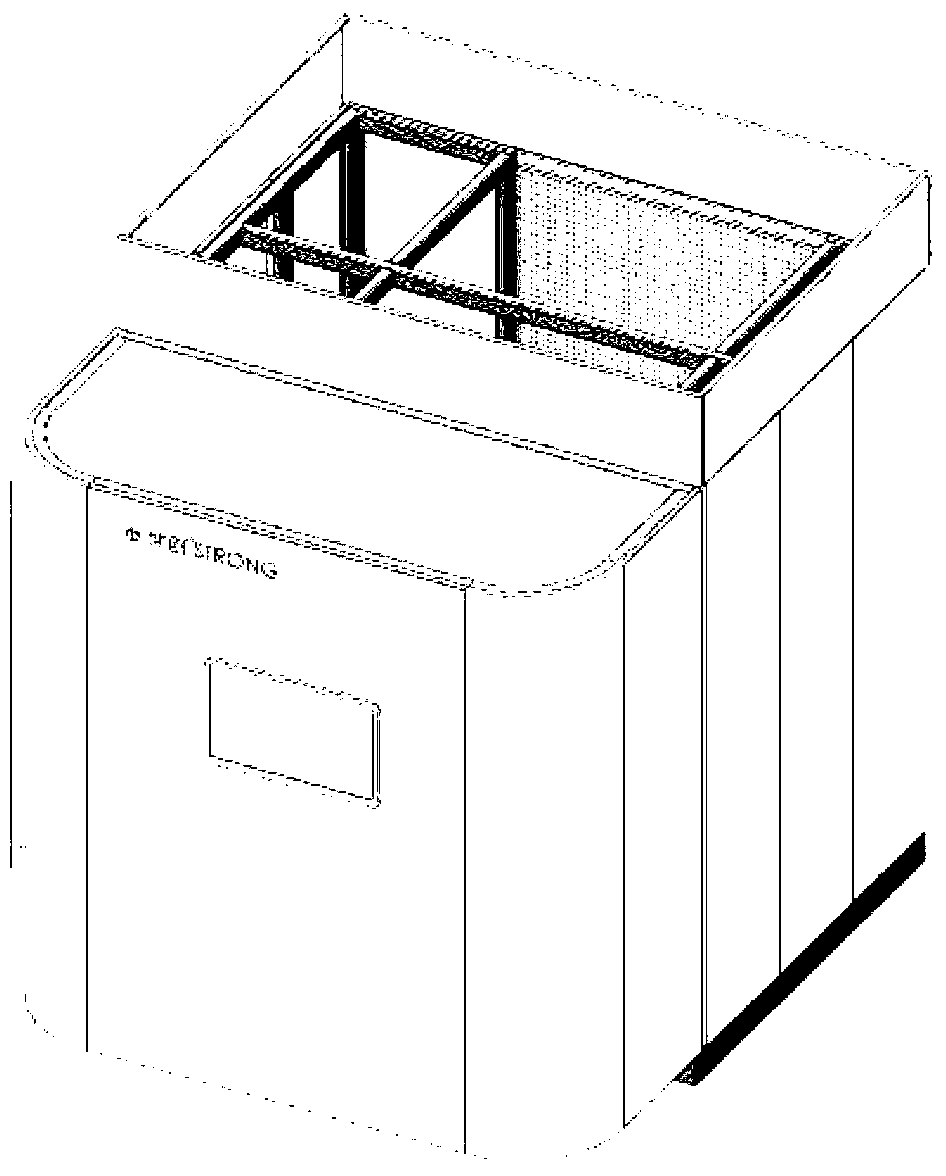

[0016] refer to figure 1 and figure 2 , the door body structure of the coating equipment involved in this embodiment includes a vacuum door body 4 and a vacuum chamber door cover 3, and the vacuum door body 4 is sealed and connected with the vacuum chamber cavity 2 to form a sealed vacuum chamber with a cylindrical structure; A vacuum chamber body cover 1 is provided on the outer surface of the vacuum chamber body 2, and the vacuum chamber is enclosed as a whole by the vacuum chamber door cover 3 and the vacuum chamber body cover 1 to form a vacuum chamber enclosure structure; the vacuum chamber body 4 includes Two or more facades are provided with observation windows 5 on the facades, and camera devices 7 are installed on the observation windows 5; on the front of the vacuum chamber door cover 3, a display screen 8 is installed for video monitoring and process monitoring. .

[0017] In this example:

[0018] An infrared temperature measuring device 6 may be provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com