Modified silica gel material, preparation method and applications thereof

A modified technology of silica gel, applied in the field of silica gel, can solve problems such as limited effects, and achieve the effects of stabilizing the body, relieving muscle soreness, and adjusting the balance of body functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

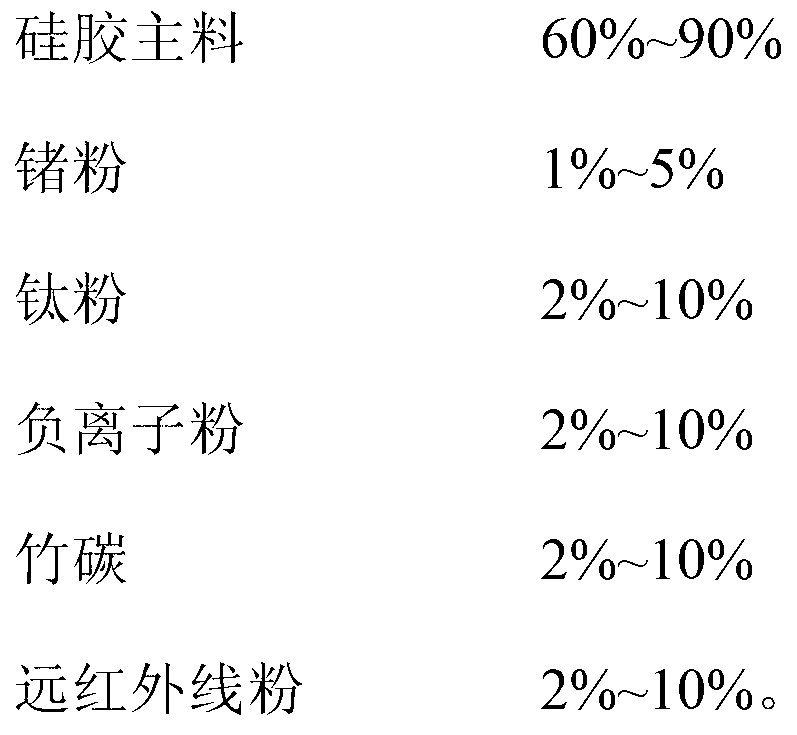

[0036] A modified silica gel material consists of the following components by weight percentage:

[0037]

[0038] The method comprises the steps of:

[0039] (1) Raw material preparation: mix the raw materials according to the weight percentage, fully stir evenly, depressurize and remove air bubbles;

[0040] (2) Molding or injection molding: Put or inject the prepared raw materials into the preset mold, heat the temperature to 220°C, and heat for 380s, and the modified silicone material can be obtained after the mold is released.

Embodiment 2

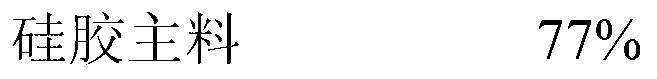

[0042] A modified silica gel material consists of the following components by weight percentage:

[0043]

[0044]

[0045] The method comprises the steps of:

[0046] (1) Raw material preparation: mix the raw materials according to the weight percentage, fully stir evenly, depressurize and remove air bubbles;

[0047] (2) Molding or injection molding: Put or inject the prepared raw materials into the preset mold, heat the temperature to 210°C, and heat for 580s, and the modified silicone material can be obtained after the mold is released.

Embodiment 3

[0049] A modified silica gel material consists of the following components by weight percentage:

[0050]

[0051] The method comprises the steps of:

[0052] (1) Raw material preparation: mix the raw materials according to the weight percentage, fully stir evenly, depressurize and remove air bubbles;

[0053] (2) Molding or injection molding: Put or inject the prepared raw materials into the preset mold, heat the temperature to 230°C, and heat for 400s, and the modified silicone material can be obtained after the mold is released.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com