A method for extracting two secondary salts from coke oven gas desulfurization salty waste liquid

A coke oven gas and salt-containing waste liquid technology, applied in the direction of thiosulfate/dithionite/polythionate, ammonium sulfate, thiocyanate, etc., can solve the problem of inability to purify economic value thiosulfate Ammonium sulfate, high crystallization concentration and temperature control requirements, low economic value of ammonium sulfate, etc., to achieve the effect of large treatment process flexibility, avoiding secondary pollution, and large production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

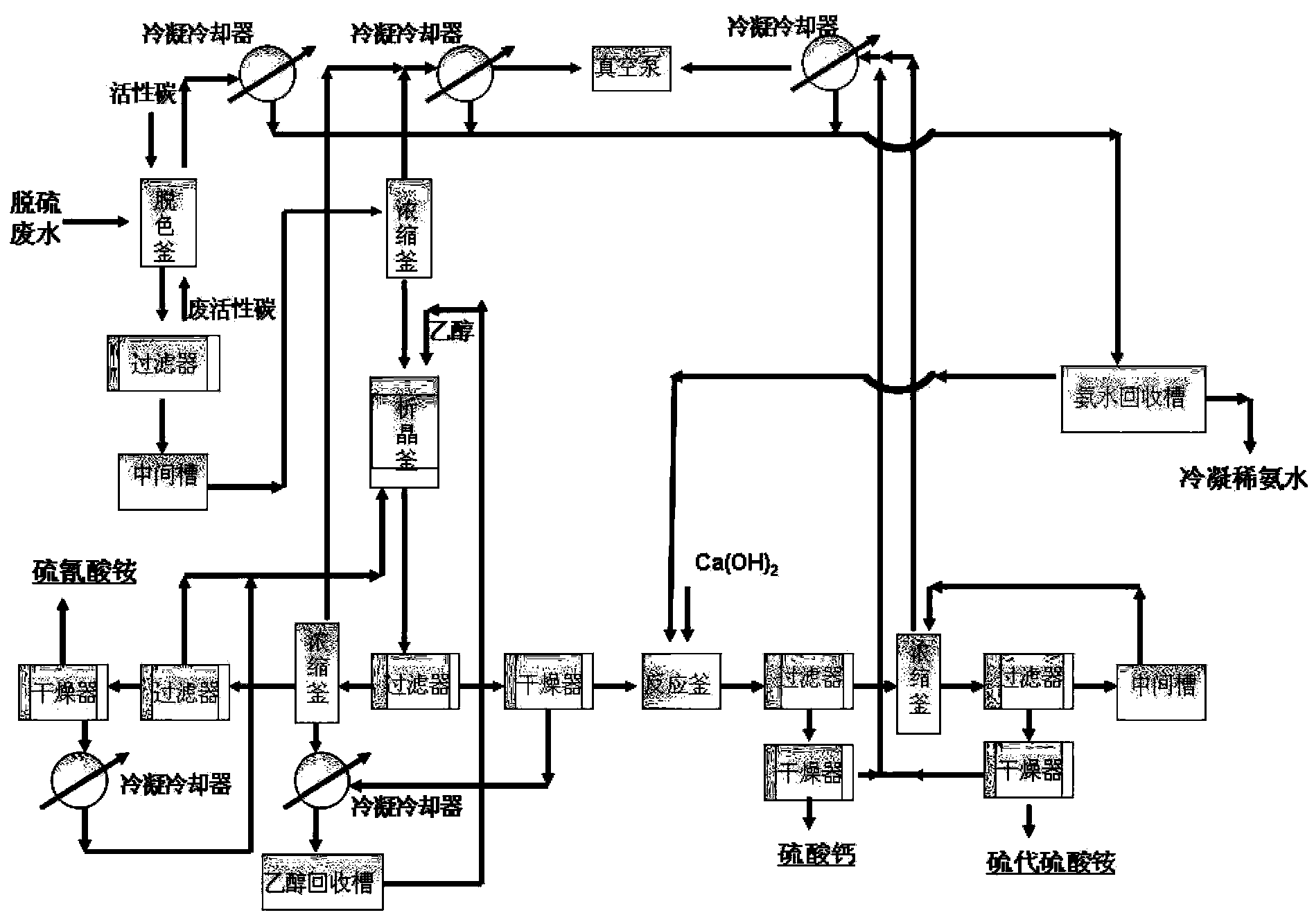

[0047] Embodiment 1: refer to figure 1 The process flow of salt extraction from desulfurization waste liquid is shown

[0048] 1000kg of coke oven gas desulfurization and decyanation waste liquid from sulfur paste (containing about 13% ammonium thiocyanate, 9% ammonium thiosulfate, and 8% ammonium sulfate)

[0049] Step 1: Decolorization and impurity removal: add 1kg of 0.1% (w / w) activated carbon to the desulfurization waste liquid, keep it warm at 100°C for 30 minutes, and then filter to obtain the decolorized filtrate and activated carbon filter cake (the activated carbon filter cake will be sent to a professional recycling enterprise for regeneration treatment ).

[0050] Step 2: Concentrate the decolorized solution under reduced pressure: Concentrate the filtrate of step 1 under reduced pressure at 70°C (vacuum degree 70mmHg) until the specific gravity of the system is 1.24. Stop concentration (water content is 18% (w / w)), and the concentrated The system is kept warm an...

Embodiment 2

[0057] Embodiment 2: refer to figure 1 The process flow of salt extraction from desulfurization waste liquid is shown

[0058] 1000kg of coke oven gas desulfurization and decyanation waste liquid from sulfur paste (containing about 15% ammonium thiocyanate, 6% ammonium thiosulfate, and 9% ammonium sulfate)

[0059] Step 1: Decolorization and impurity removal: add 5kg of 0.5% (w / w) activated carbon to the desulfurization waste liquid, heat it at 80°C for 45 minutes, and then filter to obtain the decolorized filtrate and activated carbon filter cake (the activated carbon filter cake will be sent to a professional recycling enterprise for regeneration treatment ).

[0060] Step 2: Concentrate the decolorized solution under reduced pressure: Concentrate the filtrate of step 1 under reduced pressure at 80°C (vacuum degree 90mmHg) until the specific gravity of the system is 1.22. Stop concentrating (water content is 20% (w / w)). The system is kept warm and transferred to the crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com