Catalyst for preparing propylene by disproportionation of ethylene and butane and preparation method of catalyst

A catalyst, butene technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as large gaps, unindustrialization, and no industrialization reports , to achieve the effect of improving the utilization rate and improving the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

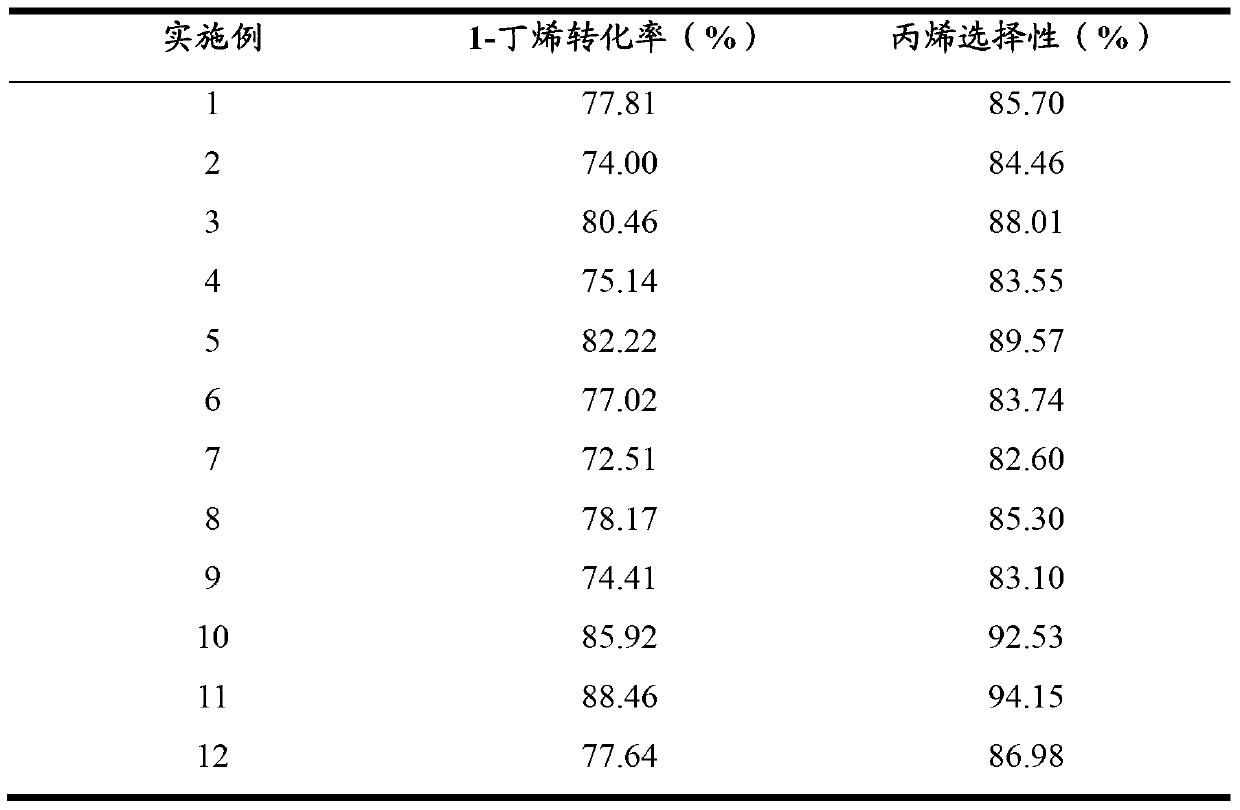

Examples

Embodiment 1

[0026] Weigh 19g specific surface area is 300m 2 / g SiO 2 , baked at 550 ° C for 4h. After dissolving 0.53g of zirconium nitrate in 20ml of water, impregnate the calcined silica for 2 hours, then place it in an oven at 100°C for 10 hours, and then bake it at 550°C for 4 hours in an air atmosphere to obtain SiO 2 -ZrO 2 Carrier, where ZrO 2 The mass fraction is 1%. Weigh 2.413g of ammonium tungstate, 0.324g of ammonium molybdate, and 0.016g of ammonium perrhenate according to the ratio of tungsten, molybdenum and rhenium oxides, heat and dissolve with 200ml of deionized water and impregnate them into SiO 2 -ZrO 2 Carrier, after impregnation for 5 hours, put it into an oven and dry it for 12 hours at 100°C. Prepare another 1mol / L nitric acid solution, impregnate the above-mentioned dried catalyst into the nitric acid solution, and wash it with a large amount of deionized water after soaking for 1 to 2 minutes, and wash it for 5 to 10 times. If it is 5-7, it is considered ...

Embodiment 2

[0029] Weigh 19g specific surface area is 400m 2 / g SiO 2 , roasted at 550°C for 4h, dissolved 0.53g of zirconium nitrate in 20ml of water, impregnated on the calcined silica for 2h, then put it in an oven at 100°C and dried for 10 hours, under air atmosphere, Calcined at 550°C for 4h to prepare SiO 2 -ZrO 2 Carrier, where ZrO 2 The mass fraction is 1%. Weigh ammonium tungstate, ammonium molybdate and ammonium perrhenate according to the ratio of oxides in Example 1, heat and dissolve with 200ml deionized water and impregnate them into SiO 2 -ZrO 2 Carrier, after impregnation for 5 hours, put it into an oven and dry it for 12 hours at 100°C. Prepare another 1mol / L nitric acid solution, impregnate the above-mentioned dried catalyst into the nitric acid solution, and wash it with a large amount of deionized water after soaking for 1 to 2 minutes, and wash it for 5 to 10 times. If it is 5-7, it is considered that the cleaning is complete, and then put it in an oven at 100°...

Embodiment 3

[0032] Weigh 19g specific surface area is 300m 2 / g SiO 2 , roasted at 550°C for 4h, dissolved 1.62g of zirconium nitrate in 20ml of water, impregnated on the calcined silica for 2h, then put it in an oven at 100°C and dried for 10 hours, under air atmosphere, 550 ℃ calcination for 4h to prepare SiO 2 -ZrO 2 Carrier, where ZrO 2 The mass fraction is 3%. Weigh 2.418g of ammonium tungstate, 0.331g of ammonium molybdate, and 0.017g of ammonium perrhenate according to the ratio of tungsten, molybdenum and rhenium oxides, heat and dissolve with 200ml of deionized water and impregnate them into SiO 2 -ZrO 2 Carrier, after impregnated for 5h, put it into 100℃ oven and dry for 12h. Prepare another 1mol / L nitric acid solution, impregnate the above-mentioned dried catalyst into the nitric acid solution, soak for 1 to 2 minutes, then quickly wash with a large amount of water for 5 to 10 times, and then put it in a 100°C oven for drying. Finally, the above prepared sample was place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com