Self-dispersion nanofluid heat pipe

A nanofluid, self-dispersing technology, applied in the directions of dissolution, mixer, chemical instruments and methods, can solve the problems of high heat and mass transfer performance, low viscosity, reduced dispersion stability of nanofluids, weakening the excellent characteristics of nanofluids, etc. Achieve the effect of improving stability and reliability and improving dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

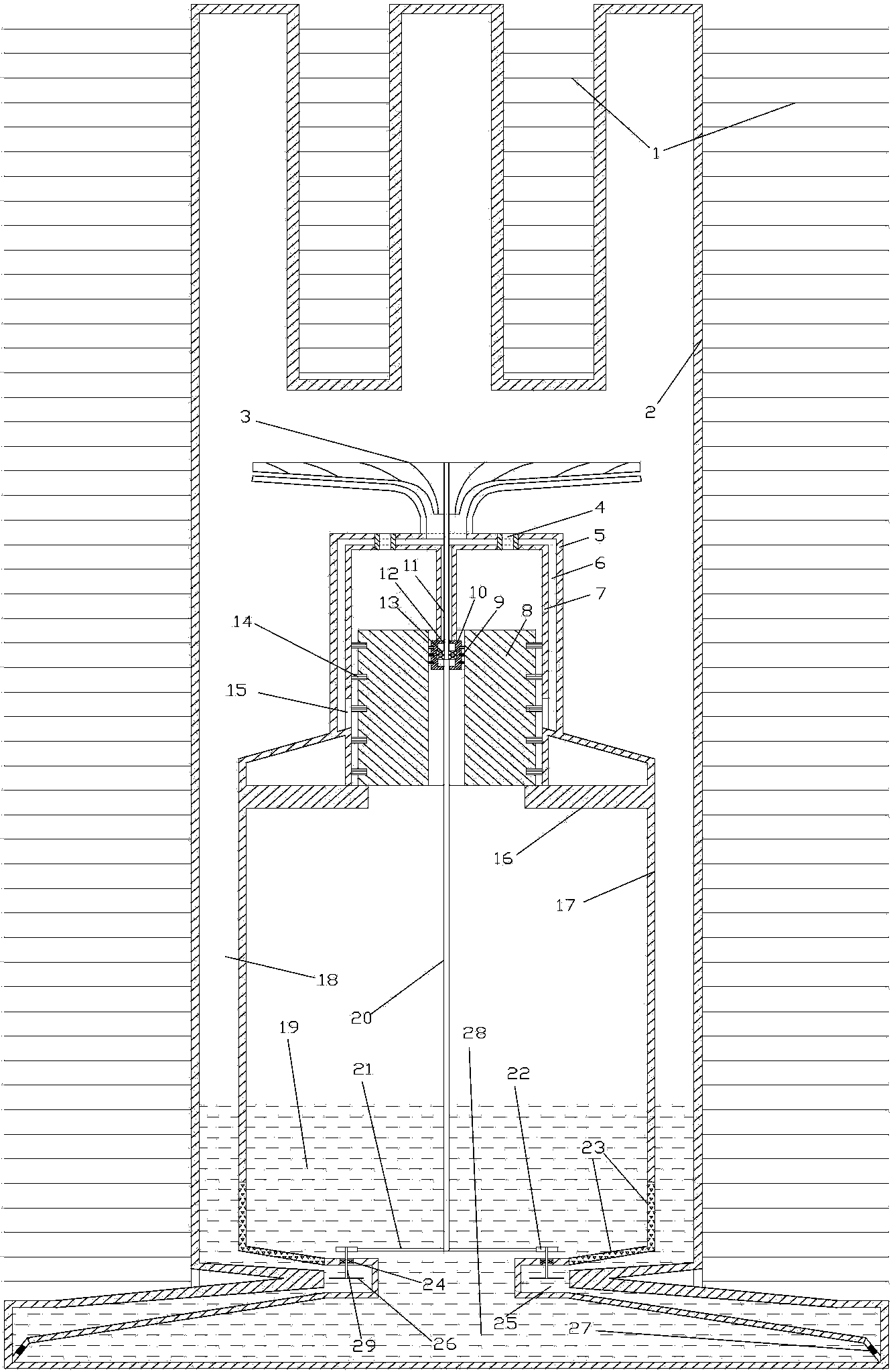

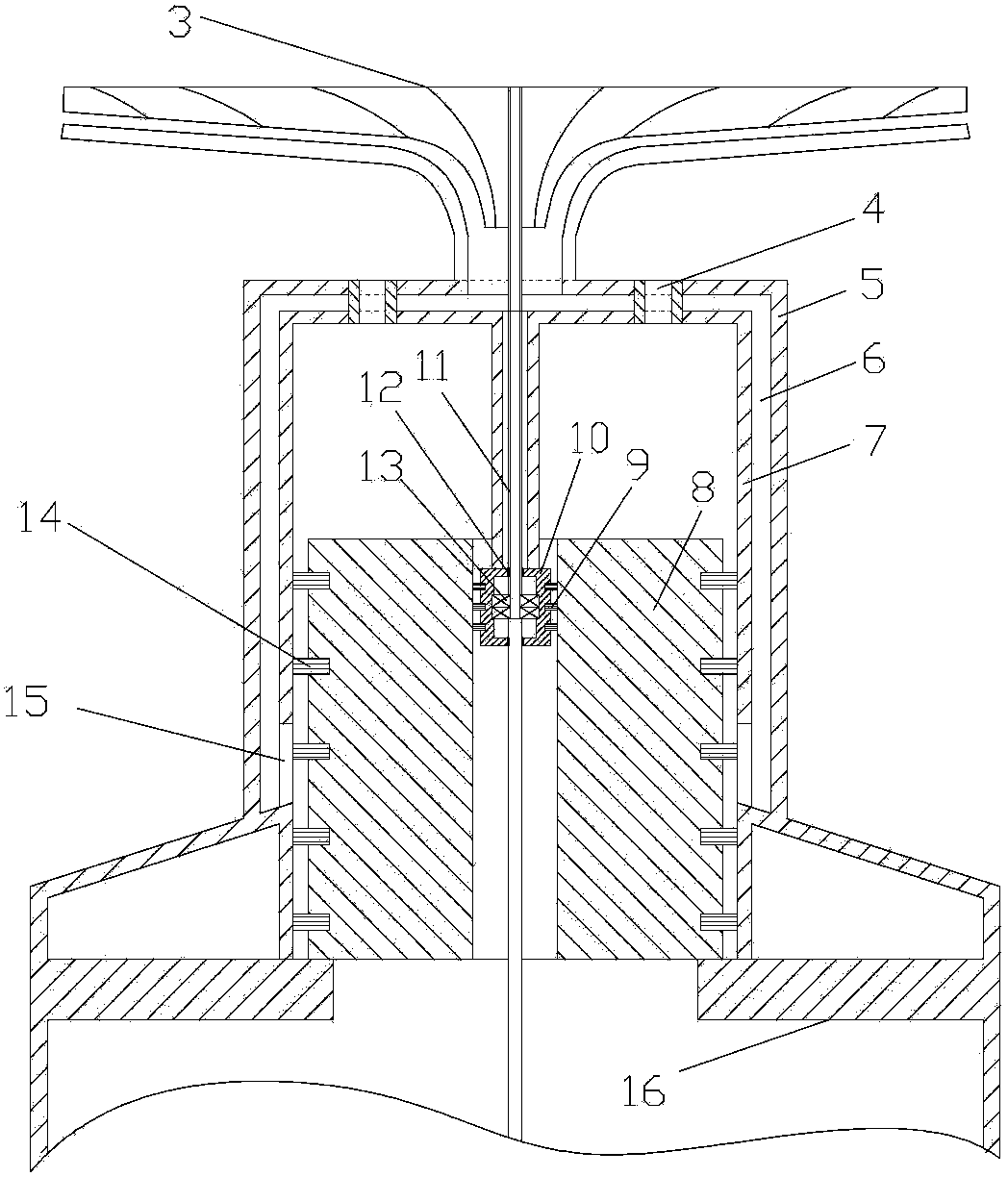

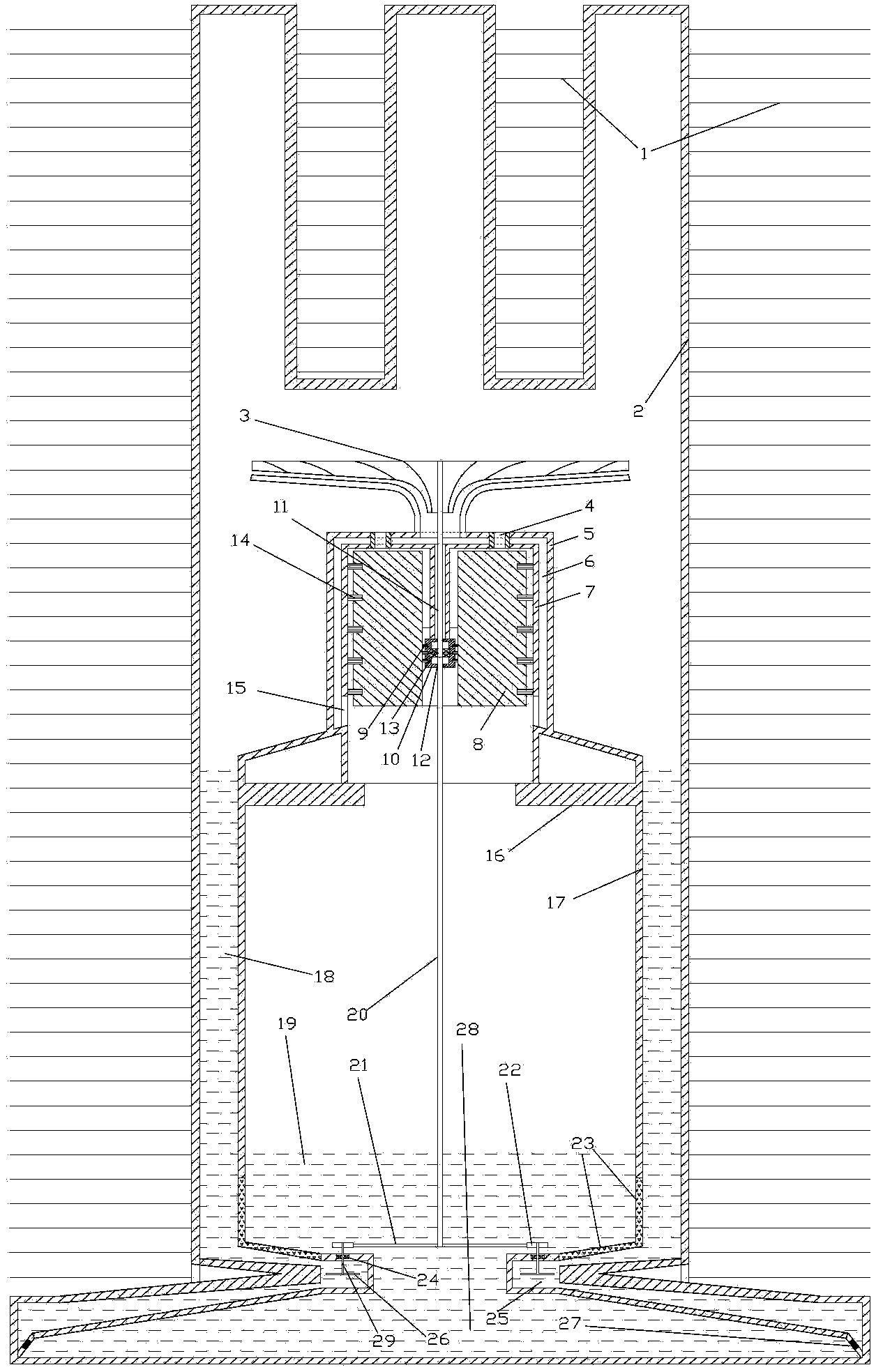

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, a self-dispersing nanofluid heat pipe of the present invention includes heat dissipation fins 1, heat pipe shell 2, and an impeller 3 located inside the heat pipe shell 2, an air injection channel 6, a piston chamber 7, a pressurization chamber 17, and a return flow channel 18 , nanofluid 19, rotating shaft 20, first gear 21, second gear 22, shear chamber 25, shear blade 26 and boiling pool 28. The cooling fins 1 are fixedly connected to the outer wall of the heat pipe housing 2 . The jet channel 6 is located outside the piston chamber 7 . An air injection channel 6 is formed between the outer wall surface 5 of the air injection channel and the wall surface of the piston chamber 7 . A bypass hole 4 is provided between the top of the outer wall surface 5 of the jet passage and the top of the wall surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com